Pulsed Laser Cleaning: The Future of Precision Cleaning Across Industries

Imagine a cleaning solution that combines pinpoint precision, environmental responsibility, and efficiency—all in one. Pulsed laser cleaning is not just a technological advancement; it is a revolutionary approach to surface preparation and restoration that spans across industries. From removing rust and coatings to preparing delicate surfaces for further processing, this method is redefining what’s possible in the world of industrial cleaning.

What is Pulsed Laser Cleaning?

Pulsed laser cleaning uses short bursts of high-energy laser light to remove contaminants from surfaces without damaging the base material. Unlike continuous wave lasers, pulsed lasers emit light in rapid, controlled bursts, offering unparalleled precision. This method is effective on a variety of surfaces, including metals, plastics, ceramics, and more.

The ability to adjust pulse duration and energy makes it highly adaptable, ensuring optimal performance for tasks ranging from heavy-duty rust removal to delicate artifact restoration.

How Does Pulsed Laser Cleaning Work?

The science behind pulsed laser cleaning lies in laser ablation. When a laser beam interacts with a surface, it heats the contaminants, causing them to expand, vaporize, or detach from the substrate. Here’s how the process works:

1. Emission of Pulsed Light:The laser generates high-intensity light pulses targeted at the contaminants.

2. Thermal and Mechanical Effects:The energy disrupts the bonds between the contaminant and the surface.

3. Controlled Cleaning:The short pulses allow precise cleaning without overheating or damaging the base material.

4. Residue-Free Process:No chemicals or abrasive materials are needed, making the process clean and environmentally friendly.

This unique mechanism ensures that pulsed laser cleaning can handle even the most challenging cleaning tasks with ease and efficiency.

Benefits of Pulsed Laser Cleaning

1. Precision and Control

The pulsed nature of the laser allows for unmatched control, enabling selective removal of contaminants without harming the underlying material.

2. Eco-Friendly Technology

Unlike traditional cleaning methods, pulsed laser cleaning eliminates the need for chemicals, abrasives, or water. This significantly reduces environmental impact and complies with modern sustainability goals.

3. Versatile Applications

From industrial equipment maintenance to heritage restoration, pulsed laser cleaning adapts to a wide range of surfaces and contaminants.

4. Minimal Downtime

The process is fast and efficient, reducing downtime in industrial settings and improving overall productivity.

5. Cost-Effective in the Long Run

While the initial investment in pulsed laser cleaning equipment may be higher, the reduced need for consumables and lower maintenance costs result in significant long-term savings.

Applications of Pulsed Laser Cleaning

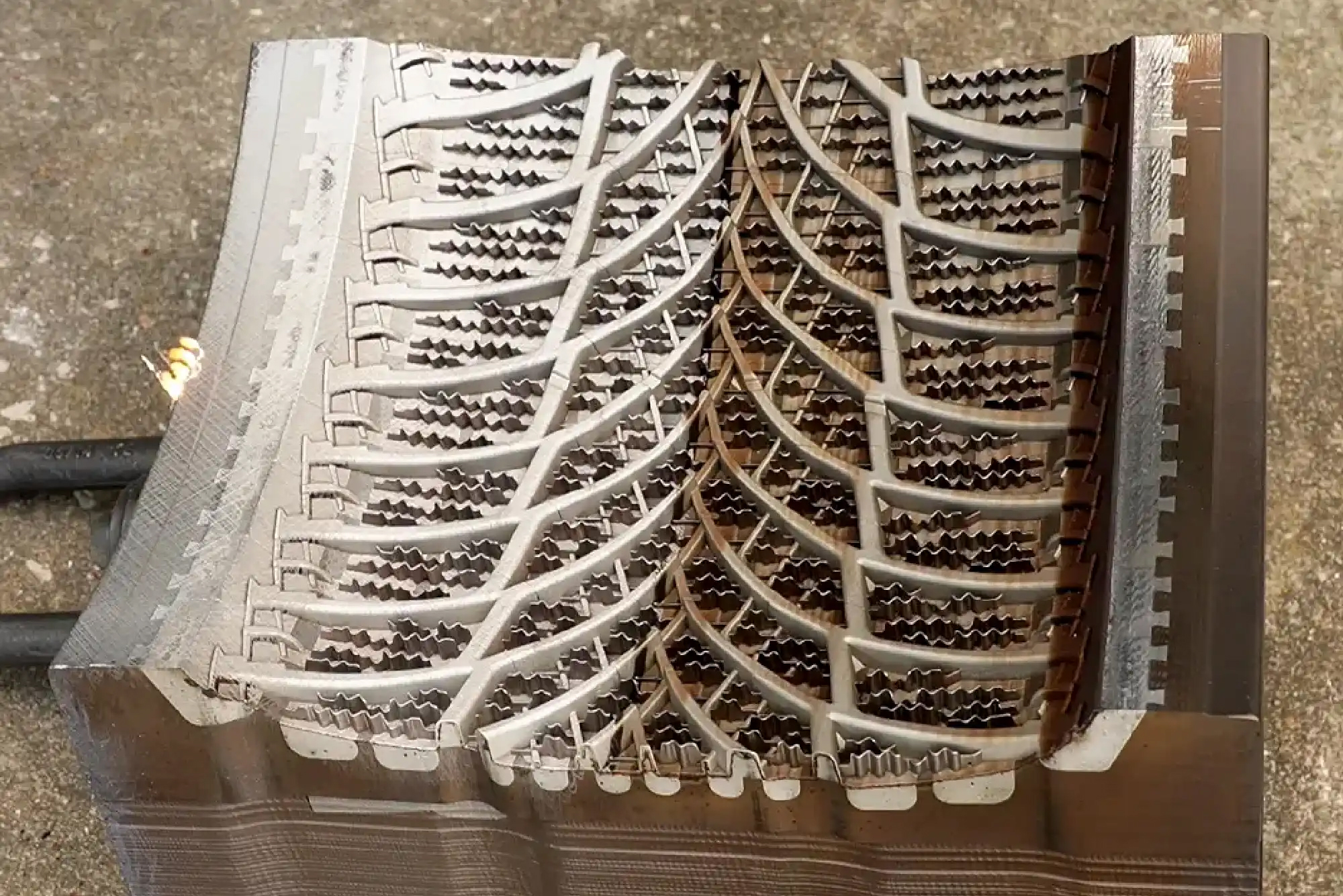

1. Rust Removal in Industrial Settings

Pulsed lasers effectively remove rust from metal surfaces, ensuring clean and smooth finishes for further processing or coating.

2. Paint and Coating Removal

This method excels at stripping paint and coatings from surfaces without damaging the substrate, making it ideal for automotive and aerospace applications.

3. Cultural Heritage Restoration

Restoration experts rely on pulsed lasers to clean delicate artifacts and sculptures, preserving their historical and aesthetic value.

4. Aerospace Component Preparation

In aerospace, precision is critical. Pulsed laser cleaning ensures that components are free of contaminants, ready for assembly or repair.

5. Medical Device Cleaning

The precision and cleanliness of pulsed laser cleaning make it suitable for cleaning sensitive medical equipment.

Factors to Consider When Choosing Pulsed Laser Cleaning Equipment

1. Material Compatibility

Different materials respond differently to laser cleaning. Ensure the equipment you choose is compatible with the surfaces you need to clean.

2. Power and Pulse Duration

The power and duration of the laser pulses should match the cleaning requirements, whether it’s heavy-duty rust removal or delicate surface preparation.

3. Portability and Flexibility

For on-site cleaning tasks, portable pulsed laser cleaning systems provide added convenience and adaptability.

4. Cost and Return on Investment

Evaluate the initial investment against the long-term savings in labor, consumables, and maintenance.

5. Training and Safety Measures

Proper training ensures operators can use the equipment safely and effectively, maximizing its benefits.

The Environmental Impact of Pulsed Laser Cleaning

Traditional cleaning methods often rely on harsh chemicals, abrasives, or water, generating significant waste and environmental hazards. Pulsed laser cleaning offers a sustainable alternative:

• No Chemical Waste:The process eliminates the need for harmful chemicals.

• Energy Efficiency:Pulsed lasers consume less energy compared to traditional methods.

• Reduced Carbon Footprint:By minimizing waste and energy consumption, laser cleaning supports global efforts to combat climate change.

This eco-friendly approach aligns with modern industrial practices and regulatory standards, making pulsed laser cleaning an environmentally responsible choice.

Frequently Asked Questions

Q: Can pulsed laser cleaning be used on sensitive surfaces?

A: Yes, the adjustable pulse duration and intensity make it ideal for cleaning delicate surfaces without causing damage.

Q: Is pulsed laser cleaning faster than traditional methods?

A: In most cases, pulsed laser cleaning is significantly faster, especially for intricate or large-scale tasks.

Q: What industries benefit the most from pulsed laser cleaning?

A: Industries such as automotive, aerospace, manufacturing, cultural heritage, and healthcare see the most benefits from this technology.

Q: How does pulsed laser cleaning compare in cost?

A: While the initial investment is higher, the long-term savings on consumables and maintenance make it a cost-effective solution.

The Future of Pulsed Laser Cleaning

As laser technology continues to evolve, pulsed laser cleaning is becoming more accessible and versatile. Future advancements may include:

• AI Integration:Smarter systems capable of optimizing cleaning parameters automatically.

• Compact Designs:Portable systems for easier use in diverse environments.

• Increased Efficiency:Higher energy efficiency and faster cleaning speeds.

Pulsed laser cleaning is more than just a cleaning method—it’s a transformative technology shaping the future of surface preparation and restoration. For industries seeking precision, sustainability, and efficiency, this innovative approach offers a cleaner, greener way forward.