Introduction

Precision laser cleaning is a game-changer. Imagine a technology so accurate that it can strip away years of corrosion, remove microscopic layers of contaminants, or prepare delicate surfaces—all without causing any harm to the material beneath. In a world where efficiency, sustainability, and accuracy are paramount, precision laser cleaning emerges as the gold standard for surface treatment. This comprehensive guide delves into the technology, its applications, and why industries are rapidly adopting it as the ultimate cleaning solution.

1. What is Precision Laser Cleaning?

Precision laser cleaning is a non-contact method that uses focused laser beams to remove unwanted materials from surfaces. Unlike abrasive or chemical cleaning methods, it offers unparalleled accuracy, making it ideal for sensitive and intricate surfaces.

Key Features:

1. Non-Destructive: Maintains the integrity of the underlying material.

2. Eco-Friendly: Eliminates the need for harmful chemicals or abrasives.

3. Highly Accurate: Targets specific areas without affecting adjacent surfaces.

2. How Does Precision Laser Cleaning Work?

The process of precision laser cleaning relies on laser ablation. The laser energy heats and vaporizes contaminants, leaving a clean surface without any mechanical or chemical damage.

Step-by-Step Process:

1. Laser Emission: A concentrated laser beam is directed at the surface.

2. Energy Absorption: Contaminants absorb the energy, converting it into heat.

3. Vaporization: The heat causes contaminants to vaporize or disintegrate.

4. Residue-Free Surface: The underlying material remains untouched and clean.

Technical Advantages:

• Adjustable Parameters: Control power, wavelength, and focus for optimal results.

• Wide Applicability: Suitable for metals, plastics, ceramics, and even glass.

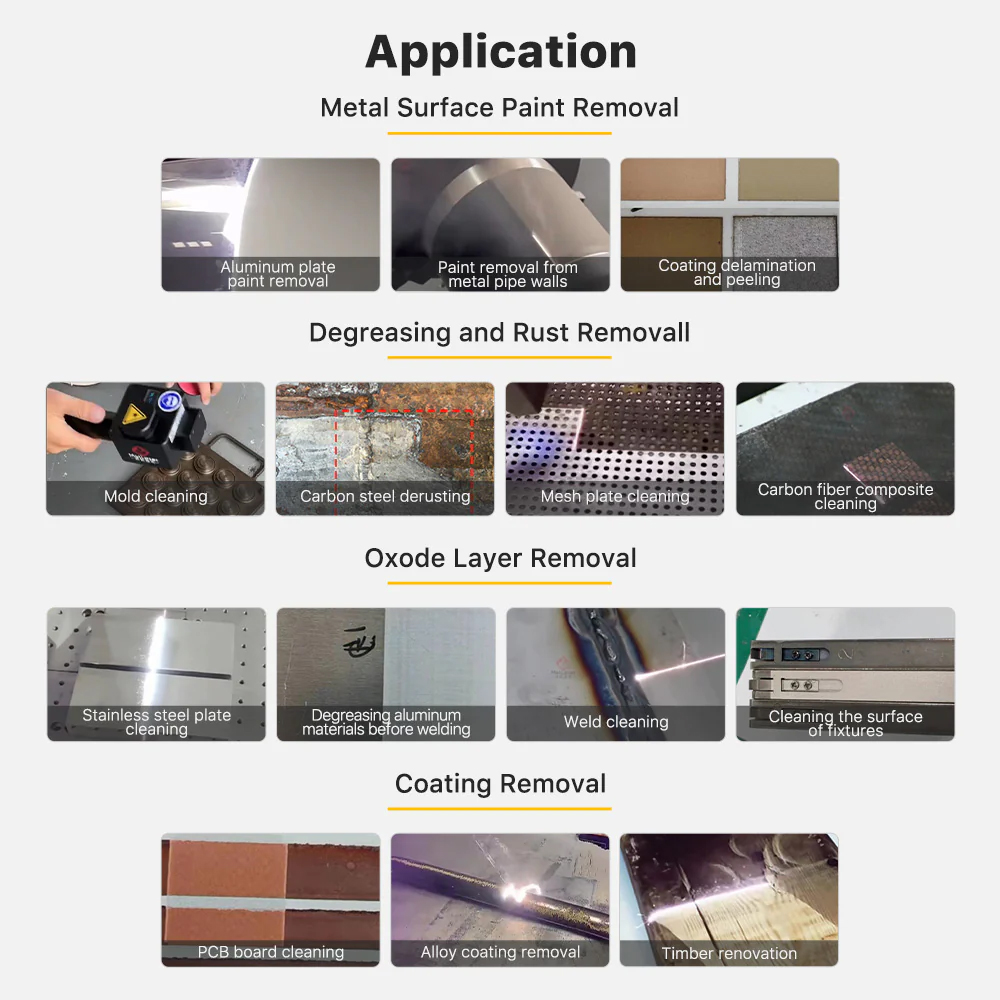

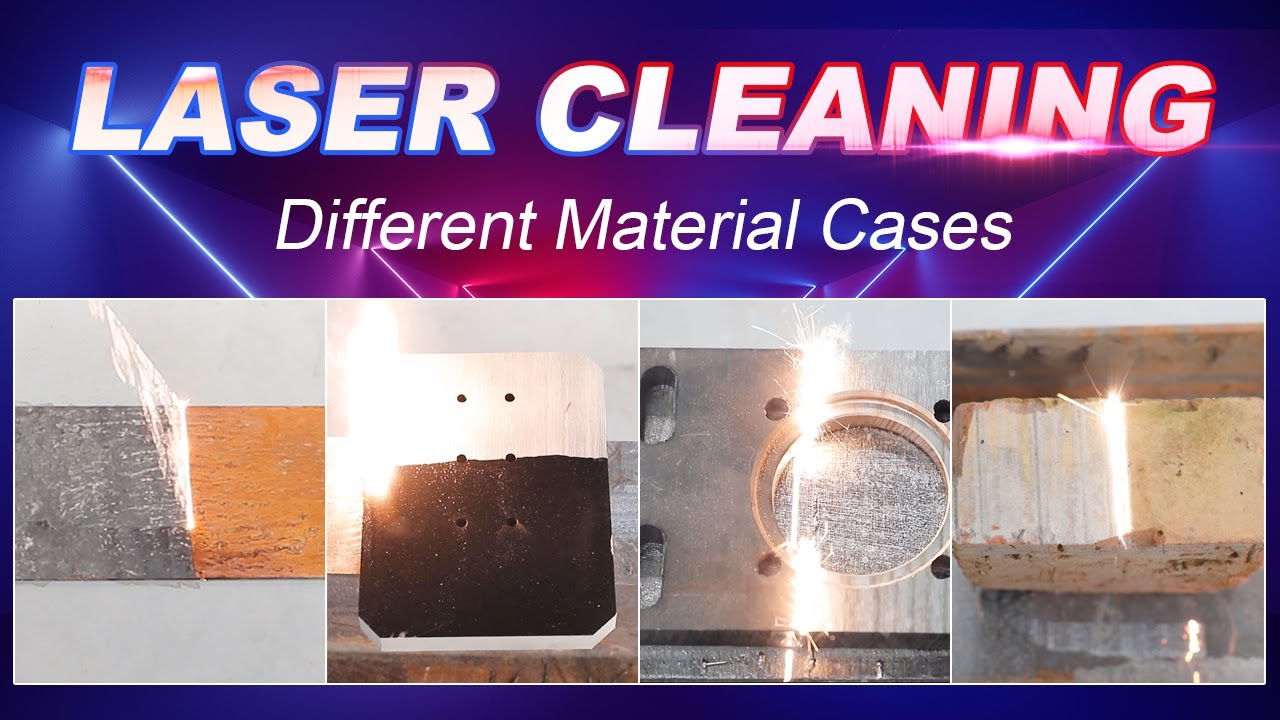

3. Applications of Precision Laser Cleaning

Precision laser cleaning is versatile and finds applications in diverse industries.

Aerospace and Defense

• Paint and Coating Removal: Prepares surfaces for inspection or re-coating.

• Debris Cleaning: Removes contaminants from critical components.

Automotive Industry

• Rust and Corrosion Removal: Restores metal parts without damaging them.

• Surface Preparation: Cleans surfaces before welding or bonding.

Electronics Manufacturing

• Circuit Board Cleaning: Removes residues without affecting sensitive components.

• Delicate Surface Treatment: Cleans intricate parts like connectors and sensors.

Cultural Heritage Preservation

• Artifact Restoration: Removes dirt and pollutants from delicate sculptures and paintings.

• Non-Invasive Cleaning: Ensures the preservation of historic materials.

Medical Industry

• Sterilization: Cleans surgical tools and medical devices.

• Microscopic Cleaning: Prepares surfaces for high-precision applications.

4. Benefits of Precision Laser Cleaning

Unmatched Precision

• Targets specific contaminants without collateral damage.

• Suitable for intricate or hard-to-reach areas.

Environmentally Friendly

• No chemicals, abrasives, or waste materials are required.

• Minimal energy consumption compared to traditional methods.

Cost-Effective

• Reduces operational costs by minimizing labor and consumables.

• Long-term savings due to lower maintenance requirements.

Increased Efficiency

• Significantly faster than manual or chemical cleaning methods.

• Improves productivity in industrial settings.

Safety and Reliability

• Non-contact operation reduces the risk of material damage.

• Automated options ensure consistent and repeatable results.

5. How to Choose the Right Precision Laser Cleaning System

When selecting a precision laser cleaning system, consider the following factors:

Key Considerations:

1. Material Type: Different materials require specific laser wavelengths and power levels.

2. Cleaning Requirements: Determine the level of precision needed for your application.

3. Portability: Handheld systems are ideal for on-site work, while stationary units suit factory settings.

4. Safety Features: Opt for systems with protective enclosures and emergency shut-offs.

5. Budget: Balance your needs with available funding to select the most cost-effective solution.

Example Use Case:

A museum restoring a centuries-old artifact can benefit from a low-power, precision laser cleaning system to safely remove dirt and grime without harming the original material.

6. Comparing Precision Laser Cleaning to Traditional Methods

Traditional Methods:

• Chemical Cleaning: Risk of residue and environmental damage.

• Abrasive Cleaning: Potential to damage sensitive surfaces.

• Manual Scrubbing: Labor-intensive and inconsistent results.

Precision Laser Cleaning:

• Non-contact and residue-free cleaning.

• Environmentally sustainable and energy-efficient.

• Delivers consistent, high-quality results across applications.

7. Advancements in Precision Laser Cleaning Technology

Precision laser cleaning continues to evolve, offering even greater efficiency and applicability.

Emerging Trends:

• AI Integration: Intelligent systems that adapt to material and contamination levels.

• Portable Designs: Lightweight and compact systems for increased mobility.

• Automation: Robotic laser cleaning for industrial-scale operations.

Future Potential:

• Cleaning applications in renewable energy sectors, such as solar panels and wind turbines.

• Enhanced precision for cleaning medical devices and pharmaceutical equipment.

8. Frequently Asked Questions About Precision Laser Cleaning

Q1: Is precision laser cleaning safe?

Yes, when operated correctly, it is completely safe and highly effective.

Q2: Can it clean all types of materials?

Precision laser cleaning works on a wide range of materials, but settings must be adjusted based on the material’s properties.

Q3: How much does a precision laser cleaning system cost?

Costs vary depending on power, features, and intended applications, ranging from affordable entry-level models to advanced industrial systems.

Q4: How does laser cleaning affect surface integrity?

It preserves surface integrity by focusing only on contaminants, leaving the material beneath untouched.

Final Thoughts

Precision laser cleaning represents a significant leap forward in surface cleaning technology. Its unparalleled accuracy, environmental sustainability, and cost efficiency make it a preferred choice across industries. Whether you’re restoring historical artifacts, preparing surfaces for manufacturing, or cleaning delicate electronic components, precision laser cleaning offers a solution that combines advanced technology with practical efficiency. Explore its potential today to revolutionize your cleaning processes.