Multi Surface Laser Cleaner: Revolutionizing Cleaning for Versatile Applications

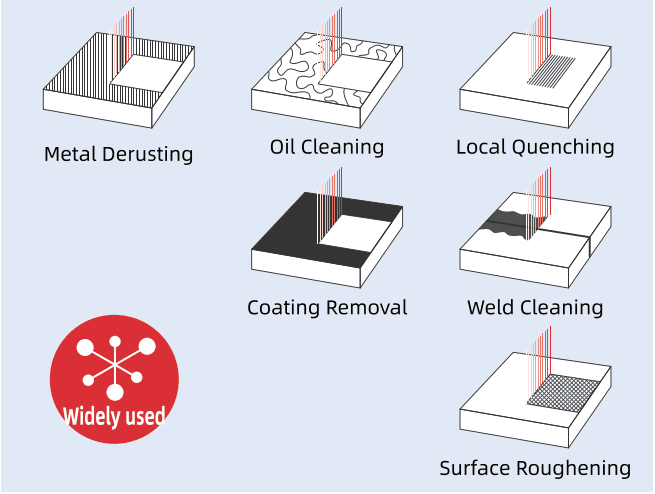

Cleaning industrial surfaces has long been a challenge, especially when dealing with diverse materials, intricate designs, and stubborn contaminants like rust, grease, and old coatings. Enter the multi surface laser cleaner—a groundbreaking solution that combines precision, versatility, and sustainability. This technology is reshaping how industries approach surface cleaning, providing an efficient, eco-friendly alternative to traditional methods.

What is a Multi Surface Laser Cleaner?

A metal laser cleaning machine is a device that uses high-energy laser beams to clean surfaces by vaporizing or breaking down contaminants. Unlike traditional cleaning methods, which rely on abrasives or chemicals, laser cleaning is a contactless process, ensuring the metal underneath remains undamaged.

This innovation eliminates the need for abrasive blasting, chemical solvents, or manual scrubbing, making it a preferred choice across industries like manufacturing, automotive, aerospace, and even cultural heritage restoration.

How Does a Multi Surface Laser Cleaner Work?

The functionality of a multi surface laser cleaner is rooted in laser ablation, a process where the laser beam interacts with surface contaminants to break them down or vaporize them.

Here’s a step-by-step breakdown of the process:

1. Laser Beam Generation:The device generates a focused beam of light.

2. Thermal Effect:The contaminants absorb the laser’s energy, causing them to disintegrate or evaporate.

3. Selective Removal:The cleaner targets only the unwanted material, preserving the surface underneath.

4. Residue-Free Finish:Unlike traditional methods, the process leaves no waste or residue, ensuring a clean and polished result.

This adaptability allows the cleaner to work on multiple surfaces without requiring significant adjustments, making it a highly versatile tool.

Benefits of Using a Multi Surface Laser Cleaner

1. Versatility Across Materials

Whether it’s removing rust from steel, cleaning grease from aluminum, or stripping paint from ceramics, a multi surface laser cleaner handles it all with ease.

2. Eco-Friendly Technology

Unlike chemical cleaning methods, laser cleaning produces no hazardous waste. The process aligns with sustainability goals, reducing the environmental impact of industrial operations.

3. Cost-Effective Operations

While the initial cost of a laser cleaner might be high, the absence of consumables, minimal maintenance needs, and faster cleaning times result in long-term savings.

4. Safety and Cleanliness

The contactless nature of laser cleaning minimizes risks to operators. Additionally, the lack of dust or toxic residues creates a safer and cleaner working environment.

5. Precision Cleaning

The machine’s precision ensures that only contaminants are removed, leaving the base material intact. This is especially useful for delicate components or high-value items.

Key Applications of Multi Surface Laser Cleaners

1. Industrial Manufacturing

Factories use these cleaners for mold cleaning, surface preparation, and removing stubborn residues from production machinery.

2. Automotive Sector

In the automotive industry, laser cleaners remove rust, paint, and grease from vehicle components, ensuring they are ready for repair or assembly.

3. Aerospace Engineering

Precision cleaning is critical in aerospace applications. Laser cleaners remove coatings, contaminants, and oxidation from sensitive parts like turbines and fuselage components.

4. Marine Industry

Ship maintenance benefits greatly from laser technology, which efficiently removes biofouling, rust, and old paint from hulls and equipment.

5. Cultural Heritage Preservation

Laser cleaners are non-invasive, making them ideal for restoring historical artifacts, sculptures, and monuments without causing damage.

The Science Behind Multi Surface Laser Cleaning

The core principle of laser cleaning lies in the interaction between the laser beam and the material surface. When the laser is directed at a contaminant, it generates a rapid thermal expansion that breaks the bond between the contaminant and the surface.

Factors influencing the cleaning process include:

• Laser Wavelength:Determines the type of materials and contaminants that can be effectively cleaned.

• Pulse Duration:Short pulses are ideal for precision cleaning, while longer pulses handle larger contaminants.

• Beam Intensity:Adjustable to suit different surfaces and cleaning requirements.

This adaptability ensures optimal performance across various applications.

How to Choose the Right Multi Surface Laser Cleaner

When selecting a laser cleaner, consider the following factors:

1. Material Compatibility

Ensure the device can handle the types of surfaces you intend to clean, from metals to non-metallic materials.

2. Portability

For on-site operations or frequent mobility, portable laser cleaners provide unmatched convenience.

3. Power Output

Higher power levels are suitable for industrial tasks, while lower levels are better for delicate or intricate work.

4. Budget and ROI

Analyze long-term cost savings against the upfront investment to ensure the machine meets your financial goals.

5. Ease of Use

Opt for models with user-friendly interfaces and automated settings to simplify operation.

The Environmental Benefits of Multi Surface Laser Cleaning

Traditional cleaning methods often involve chemicals, abrasives, and significant waste. In contrast, a multi surface laser cleaner offers a sustainable solution by eliminating harmful substances and minimizing energy consumption.

This eco-friendly approach not only reduces the carbon footprint of industrial operations but also aligns with global efforts to promote green technologies.

Frequently Asked Questions

Q: Can a multi surface laser cleaner handle sensitive materials?

A: Yes, the adjustable settings allow precise cleaning of delicate materials without causing damage.

Q: Is laser cleaning faster than traditional methods?

A: In most cases, laser cleaning is significantly faster, especially for complex or large-scale tasks.

Q: Does laser cleaning require special training?

A: While the operation is straightforward, proper training ensures optimal results and safety.

Q: What maintenance does a laser cleaner require?

A: Laser cleaners are low-maintenance devices, requiring periodic checks and cleaning of optical components.

The Future of Multi Surface Laser Cleaning

With ongoing advancements in laser technology, the capabilities of multi surface laser cleaners continue to expand. Innovations like AI integration, enhanced portability, and improved energy efficiency are making these devices more accessible and versatile.

As industries prioritize sustainability and precision, the demand for laser cleaning solutions is set to grow. Whether you’re an industrial operator, a preservation expert, or an automotive professional, a multi surface laser cleaner offers a transformative approach to surface cleaning that is efficient, safe, and environmentally responsible.

This versatile technology is not just a cleaning tool; it’s a glimpse into the future of sustainable and efficient industrial practices.