Introduction

Metal cleaning laser—three words that signify precision, efficiency, and innovation. Imagine a tool that can effortlessly remove rust, oil, paint, or other contaminants from metal surfaces while preserving the material’s integrity. The metal cleaning laser does exactly that, revolutionizing industries with its eco-friendly and highly effective cleaning process. This comprehensive guide explores the technology, applications, and benefits of metal cleaning lasers, providing you with a clear understanding of how this cutting-edge solution can transform your operations.

1. What is a Metal Cleaning Laser?

A metal cleaning laser is a device that uses focused laser beams to clean metal surfaces by removing unwanted contaminants. Unlike traditional methods, this process is non-abrasive, chemical-free, and highly precise.

Key Features:

1. Non-Contact Cleaning: Prevents damage to the underlying metal.

2. Eco-Friendly Technology: No harmful chemicals or waste byproducts.

3. Versatility: Suitable for various metals and applications.

Why It's Revolutionary:

• Enhances cleaning precision.

• Reduces environmental impact and operational costs.

2. How Does Metal Cleaning Laser Technology Work?

The cleaning process leverages laser ablation, where contaminants absorb the laser energy and are vaporized or disintegrated without affecting the metal underneath.

Step-by-Step Process:

1. Emission: A focused laser beam is directed onto the surface.

2. Absorption: Contaminants absorb the energy, converting it into heat.

3. Vaporization: The heat breaks down contaminants into harmless particles.

4. Surface Retention: The underlying metal remains intact and residue-free.

Technical Insights:

• Adjustable Power Levels: Customize for different metals and cleaning needs.

• Beam Precision: Allows for targeted cleaning of intricate areas.

3. Applications of Metal Cleaning Lasers

Metal cleaning lasers are used across various industries due to their adaptability and efficiency.

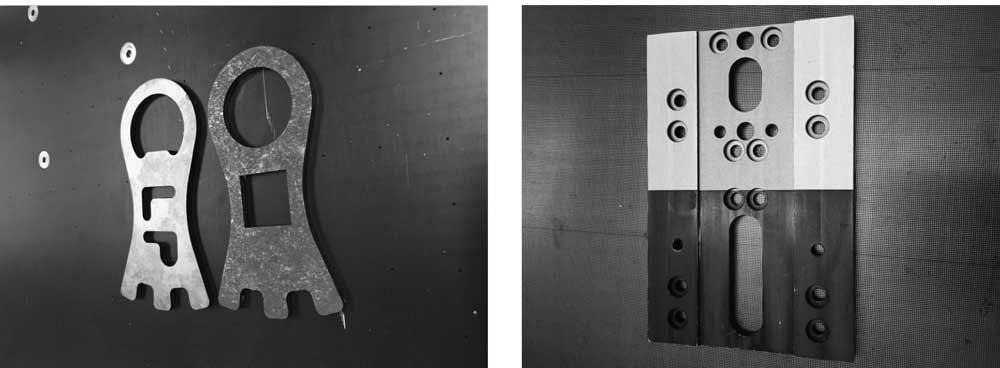

Rust Removal

Easily remove rust from steel, iron, and other metals without compromising the material’s strength.

Paint and Coating Removal

Ideal for stripping paint or coatings during surface preparation or refurbishment projects.

Surface Preparation

Prepare metal surfaces for welding, bonding, or coating by removing oil, grease, or oxides.

Industrial Maintenance

Clean machinery, tools, and parts in manufacturing environments to maintain efficiency.

Cultural Heritage Preservation

Restore historical metal artifacts without causing damage to the original material.

4. Benefits of Metal Cleaning Lasers

Precision Cleaning

• Targets contaminants without harming the base material.

• Perfect for detailed and intricate surfaces.

Eco-Friendly Operation

• Eliminates the need for harmful chemicals.

• Produces no secondary waste, making disposal easier.

Cost Efficiency

• Reduces labor and material costs.

• Long-term savings due to minimal maintenance and consumable requirements.

Speed and Efficiency

• Cleans faster than traditional methods.

• Minimizes downtime in industrial applications.

Safety and User-Friendliness

• Non-contact operation ensures operator safety.

• Automated systems reduce the risk of errors.

5. Factors to Consider When Choosing a Metal Cleaning Laser

Selecting the right laser depends on your specific requirements and budget.

Key Considerations:

1. Power Output: High power for industrial tasks; lower power for detailed work.

2. Portability: Handheld models for flexibility; stationary systems for large-scale operations.

3. Adjustability: Machines with customizable settings for beam focus and intensity.

4. Safety Features: Ensure the laser includes safety mechanisms like enclosures and emergency shut-offs.

Example Use Case:

A manufacturing facility cleaning metal molds should opt for a high-power, stationary laser with advanced controls for optimal efficiency.

6. Price Ranges for Metal Cleaning Lasers

Metal cleaning lasers vary in cost based on their features, power, and intended use.

Entry-Level Models:

• Price Range: $5,000 – $10,000

• Use Case: Small-scale or personal projects.

Mid-Range Models:

• Price Range: $10,000 – $30,000

• Use Case: Medium-sized industrial applications.

High-End Models:

• Price Range: $30,000+

• Use Case: Large-scale or highly specialized tasks.

7. Comparing Metal Cleaning Lasers to Traditional Methods

Traditional Cleaning Methods:

• Chemical Cleaning: Risk of environmental damage and hazardous waste.

• Abrasive Techniques: Potential to damage the metal surface.

• Manual Scrubbing: Labor-intensive and inconsistent results.

Metal Cleaning Lasers:

• Non-contact and non-abrasive, ensuring surface integrity.

• Environmentally friendly with no secondary waste.

• Faster, safer, and more precise than conventional methods.

8. Common Questions About Metal Cleaning Lasers

Q1: Are metal cleaning lasers safe to use?

Yes, modern machines include safety features like enclosures and emergency shut-offs to protect users.

Q2: Can lasers clean all types of metal?

Yes, but the machine settings need to be adjusted based on the type and condition of the metal.

Q3: How much maintenance do these machines require?

Minimal maintenance compared to traditional cleaning equipment, making them cost-effective in the long run.

Q4: Are they suitable for outdoor use?

Portable models can be used outdoors for on-site cleaning tasks.

Final Reflections

Metal cleaning lasers represent a significant leap in surface cleaning technology. Their precision, efficiency, and eco-friendliness make them indispensable across industries, from manufacturing to cultural restoration. By understanding their capabilities and applications, businesses can harness this innovative technology to improve processes, reduce costs, and contribute to a sustainable future. Explore the potential of metal cleaning lasers and elevate your operations today.