Unlocking the Power of Laser Welding Solutions

Laser welding solutions represent the pinnacle of precision and efficiency in modern manufacturing. As industries evolve, the demand for tailored welding systems capable of addressing complex challenges continues to grow. This article examines the innovative world of laser welding solutions, focusing on their applications, benefits, and how they drive industrial transformation.

Why Laser Welding Solutions Matter

In an era where precision, speed, and adaptability are critical, laser welding has emerged as a game-changer. This technology offers unparalleled accuracy, minimal thermal distortion, and compatibility with a wide range of materials.

Key Features of Laser Welding Solutions

1. Precision Engineering: Achieve micron-level accuracy.

2. Minimal Heat-Affected Zone (HAZ): Preserve material integrity and aesthetics.

3. Speed and Efficiency: Reduce cycle times and boost productivity.

4. Versatility: Seamlessly weld different metals and alloys.

5. Automation-Friendly: Integrate with advanced robotic systems.

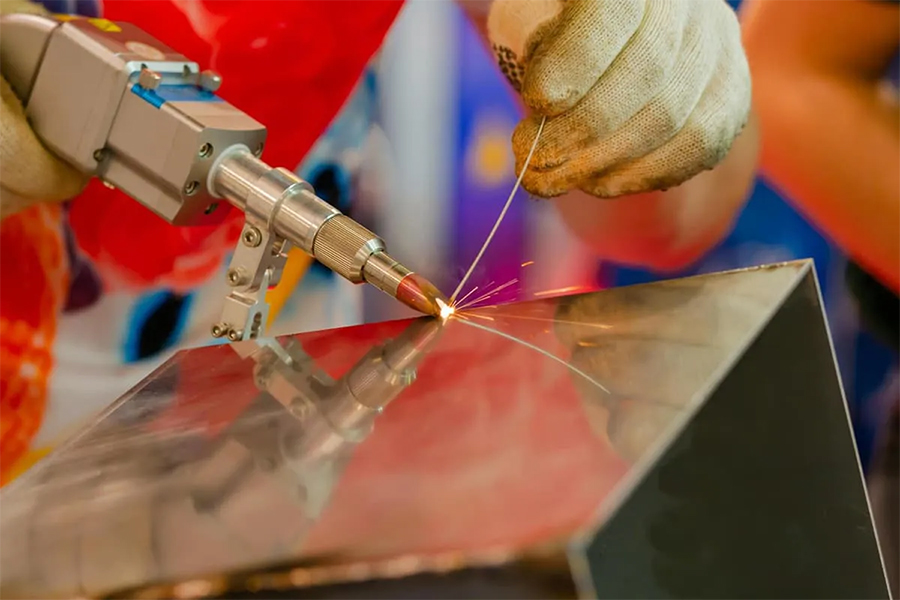

The Mechanics Behind Laser Welding

Understanding how laser welding solutions work helps highlight their advantages.

Core Components

• Laser Source: Generates the concentrated light beam.

• Delivery System: Guides the beam to the workpiece using optics.

• Cooling Mechanism: Maintains optimal temperatures for equipment longevity.

The Process in Action

Laser welding works by focusing a high-intensity beam of light onto a small area, melting the material and forming a precise weld. Keyhole welding and heat conduction welding are the two main techniques used, each suited for specific applications.

Applications of Laser Welding Solutions

Laser welding solutions have revolutionized industries ranging from aerospace to medical technology.

1. Aerospace and Defense

Precision and reliability are critical in aerospace manufacturing. Laser welding ensures defect-free joins in components exposed to extreme conditions.

2. Automotive Industry

The automotive sector benefits from laser welding’s ability to handle lightweight materials and produce consistent results for chassis and battery assemblies.

3. Medical Devices

Laser welding is indispensable in manufacturing surgical instruments and implants, where precision and biocompatibility are non-negotiable.

4. Electronics

In microelectronics, laser welding provides the precision needed to assemble delicate components like circuit boards and sensors.

5. Jewelry and Luxury Goods

Laser welding offers seamless repairs and intricate designs in high-value items, preserving their aesthetic appeal.

Benefits of Adopting Laser Welding Solutions

1. Enhanced Product Quality

Laser welding produces smooth, defect-free welds with minimal distortion, ensuring superior product quality.

2. Cost Efficiency

While the initial investment may be significant, reduced rework, lower material wastage, and higher throughput offset costs in the long run.

3. Sustainability

Laser welding is an eco-friendly option, generating minimal waste and reducing energy consumption compared to traditional methods.

4. Scalability

From small-scale prototypes to large-volume production, laser welding solutions adapt to different manufacturing needs.

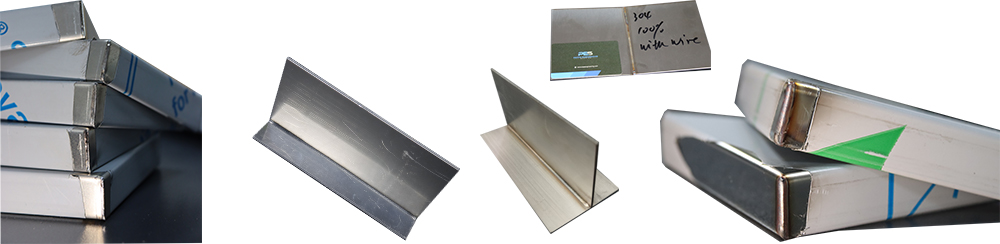

Customizing Laser Welding Solutions

1. Tailored System Design

Customized systems meet the specific requirements of industries, whether for micro-welding in electronics or high-power applications in aerospace.

2. Material Compatibility

Advanced laser systems accommodate a variety of materials, including exotic alloys and non-metals.

3. Integration with Automation

Pairing laser welding with robotics streamlines production lines, enhancing efficiency and consistency.

4. Modular Configurations

Modular designs allow for easy upgrades and adjustments as production demands evolve.

Trends Shaping the Future of Laser Welding

1. AI and Machine Learning

Artificial intelligence optimizes welding parameters in real-time, reducing errors and improving productivity.

2. Portable Welding Solutions

Compact systems bring laser welding capabilities to remote locations, opening new possibilities for fieldwork.

3. Green Manufacturing

Laser welding aligns with sustainability goals by reducing material and energy usage, making it a preferred choice for eco-conscious industries.

4. Hybrid Welding Systems

Combining laser welding with other methods creates versatile solutions for complex projects.

How to Choose the Right Laser Welding Solution

1. Assess Application Needs

Identify the specific requirements of your project, including material type, thickness, and production volume.

2. Evaluate System Capabilities

Ensure the chosen system can deliver the required precision, speed, and scalability.

3. Consider Maintenance and Support

Opt for solutions that offer reliable technical support and easy maintenance to minimize downtime.

4. Factor in Long-Term Value

Focus on systems that balance upfront costs with operational savings and enhanced productivity.

Laser welding solutions redefine the standards of manufacturing excellence. Their precision, efficiency, and adaptability make them indispensable tools for industries striving for innovation and sustainability. With the right approach, adopting laser welding can unlock unparalleled opportunities for growth and success.