The Power of Laser Welding and Cutting Machines: A Comprehensive Guide

In the dynamic world of manufacturing, the laser welding and cutting machine stands as a beacon of innovation. Combining precision with versatility, these machines are transforming how industries approach metalwork and fabrication. This guide delves into the capabilities, applications, and benefits of laser welding and cutting machines, offering insights to help professionals and hobbyists alike.

What is a Laser Welding and Cutting Machine?

A laser welding and cutting machine is an advanced tool that utilizes concentrated laser beams to weld or cut materials with exceptional accuracy. These machines are renowned for their ability to handle intricate designs and demanding projects, offering a seamless blend of speed, precision, and reliability.

Features of Laser Welding and Cutting Machines

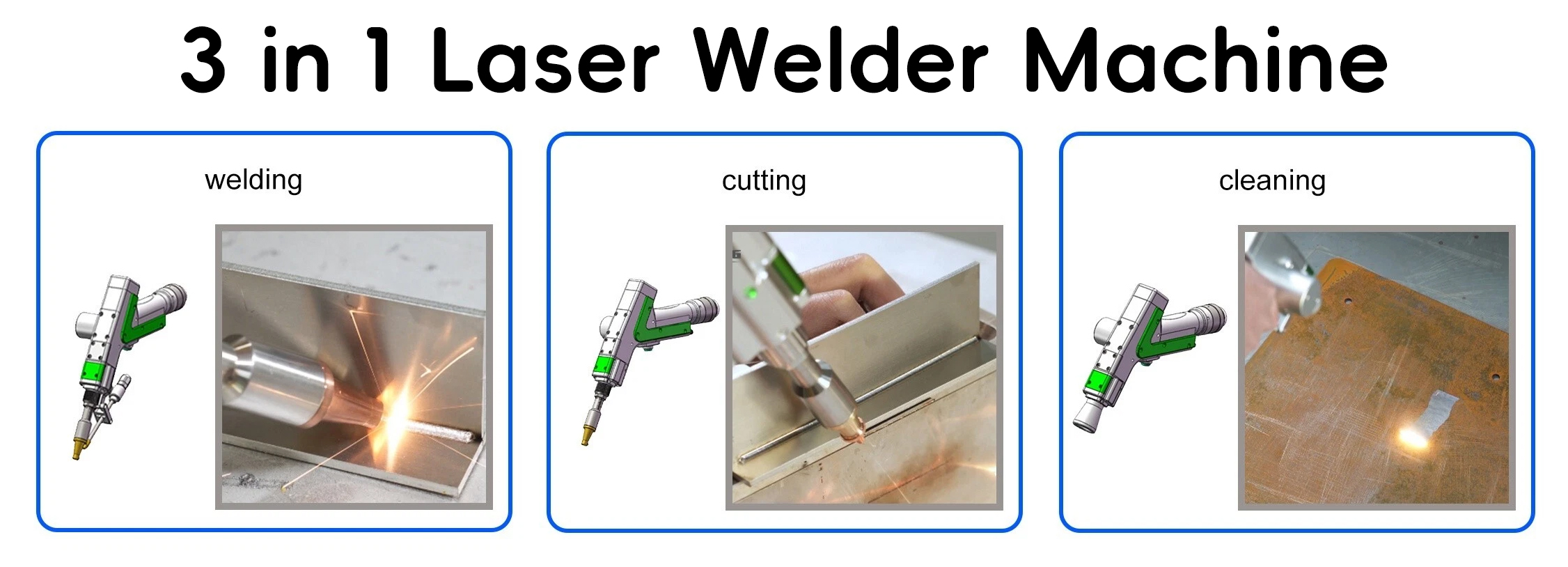

Dual Functionality

Combining welding and cutting in a single machine, these tools streamline operations and eliminate the need for separate equipment.

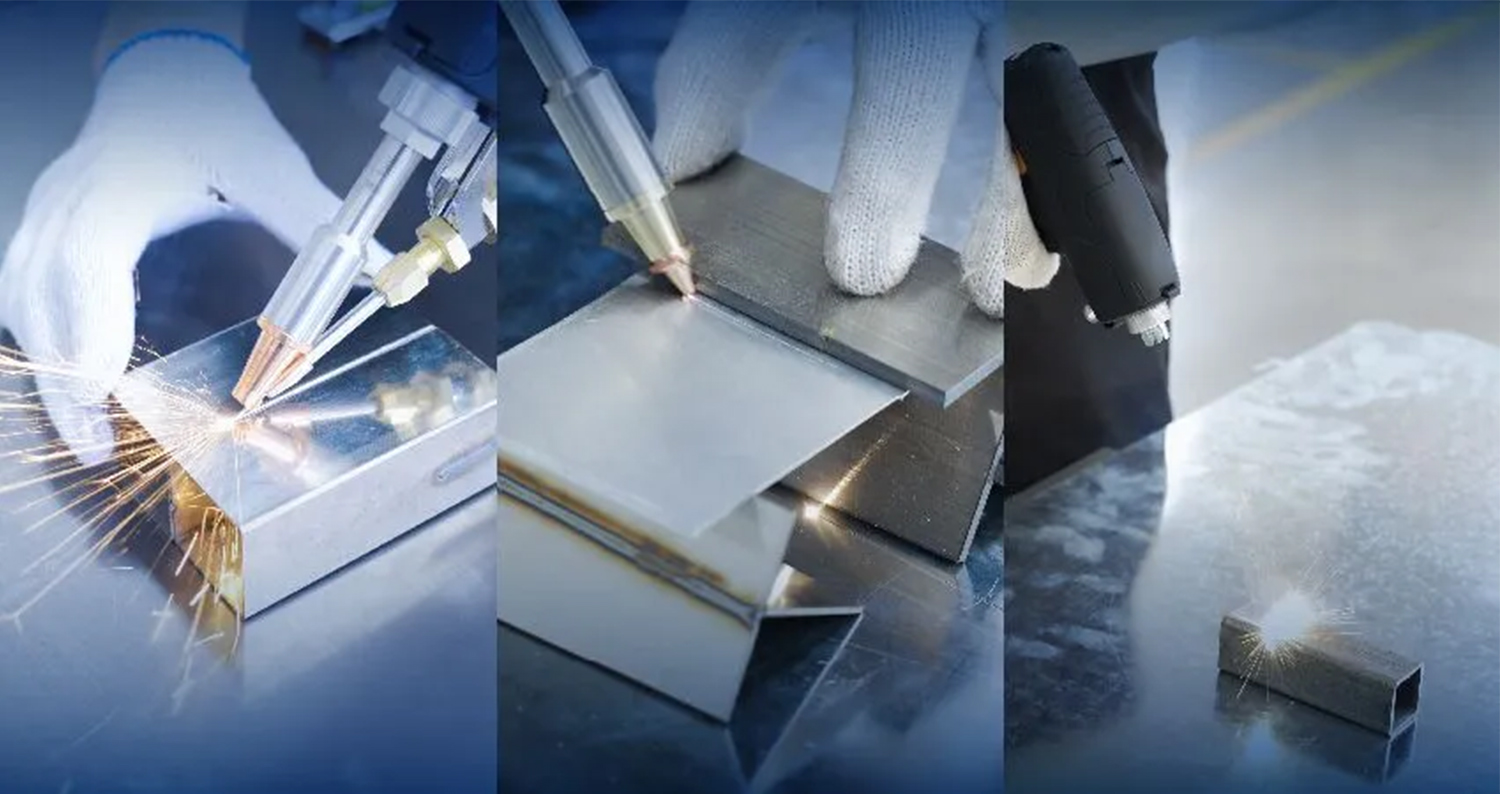

Precision Engineering

The laser beam’s concentrated energy ensures clean cuts and strong welds, even on delicate or complex materials.

Energy Efficiency

Compared to traditional methods, laser machines minimize energy waste, reducing operational costs significantly.

Material Compatibility

Whether it’s stainless steel, aluminum, or advanced composites, these machines handle a diverse range of materials with ease.

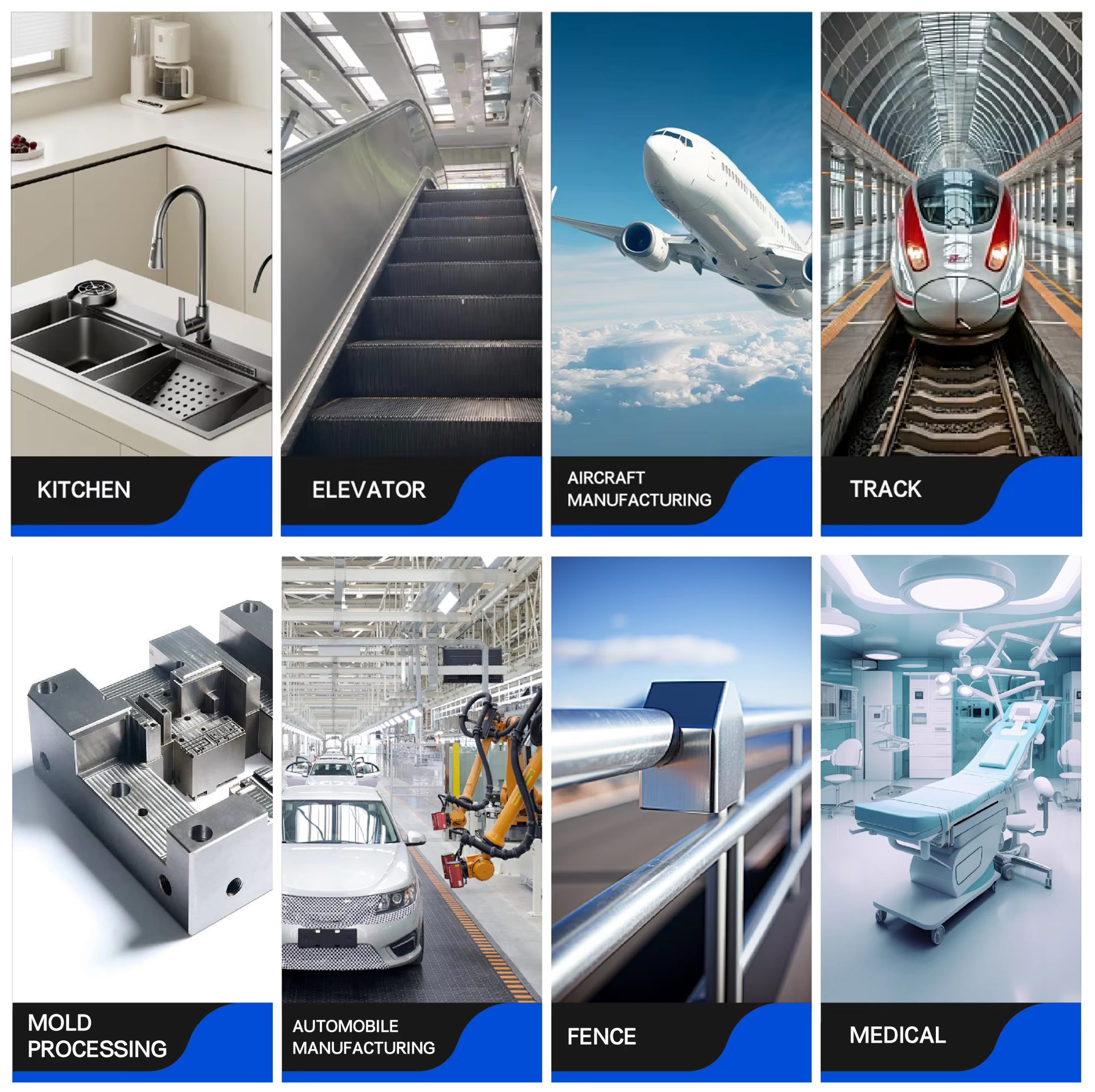

Applications Across Industries

Laser welding and cutting machines find use in various industries due to their versatility:

• Automotive Manufacturing: Crafting lightweight components and intricate designs.

• Aerospace Engineering: Ensuring precision in parts critical to safety and performance.

• Medical Device Production: Creating micro welds for surgical instruments and implants.

• Electronics: Achieving detailed cuts for circuit boards and connectors.

• Art and Design: Enabling creative freedom in sculpture and decorative elements.

Advantages Over Traditional Methods

When compared to conventional welding and cutting techniques, laser machines offer several distinct advantages:

| Feature | Laser Machines | Traditional Methods |

|---|---|---|

| Precision | Exceptional | Moderate |

| Heat-Affected Zone | Minimal | Extensive |

| Material Deformation | Rare | Common |

| Speed | High | Variable |

| Post-Processing | Minimal or none | Often required |

How to Choose the Right Machine

Selecting the best laser welding and cutting machine involves assessing specific needs:

Power Output

The machine’s wattage determines its capability to handle various materials and thicknesses.

Work Area Size

Choose a machine with a work area suited to your project dimensions.

Software Compatibility

Modern machines often integrate with CAD and other design software for enhanced functionality.

Cooling Mechanism

Ensure the machine has an efficient cooling system to prevent overheating during prolonged use.

Ease of Use

User-friendly controls and interfaces simplify operation, even for beginners.

Maintenance Tips for Longevity

Proper maintenance ensures your laser machine delivers optimal performance over time:

• Regularly clean the optics and lens to maintain beam quality.

• Inspect and replace consumables like nozzles and mirrors as needed.

• Calibrate the machine periodically to ensure accuracy.

• Keep the machine in a clean, dust-free environment to prevent contamination.

Future of Laser Welding and Cutting Machines

As technology evolves, laser machines are expected to incorporate advanced features such as AI-based control systems and predictive maintenance. These innovations will further enhance their efficiency, making them indispensable in smart manufacturing and sustainable production practices.

Final Thoughts

Laser welding and cutting machines are redefining possibilities in fabrication and metalwork. Their ability to deliver precise results, coupled with efficiency and versatility, makes them an invaluable asset across industries. Whether you’re a seasoned professional or exploring these machines for the first time, investing in laser technology is a step toward innovation and excellence in production.

For further exploration or guidance, continue researching trusted sources and seek expert consultations tailored to your specific needs.