The Art and Science of Laser Micro Welding

Laser micro welding stands at the forefront of precision engineering, bridging gaps and fusing materials with microscopic accuracy. It is a transformative technology that has found its way into industries demanding unparalleled precision, such as electronics, medical devices, and aerospace.

What is Laser Micro Welding?

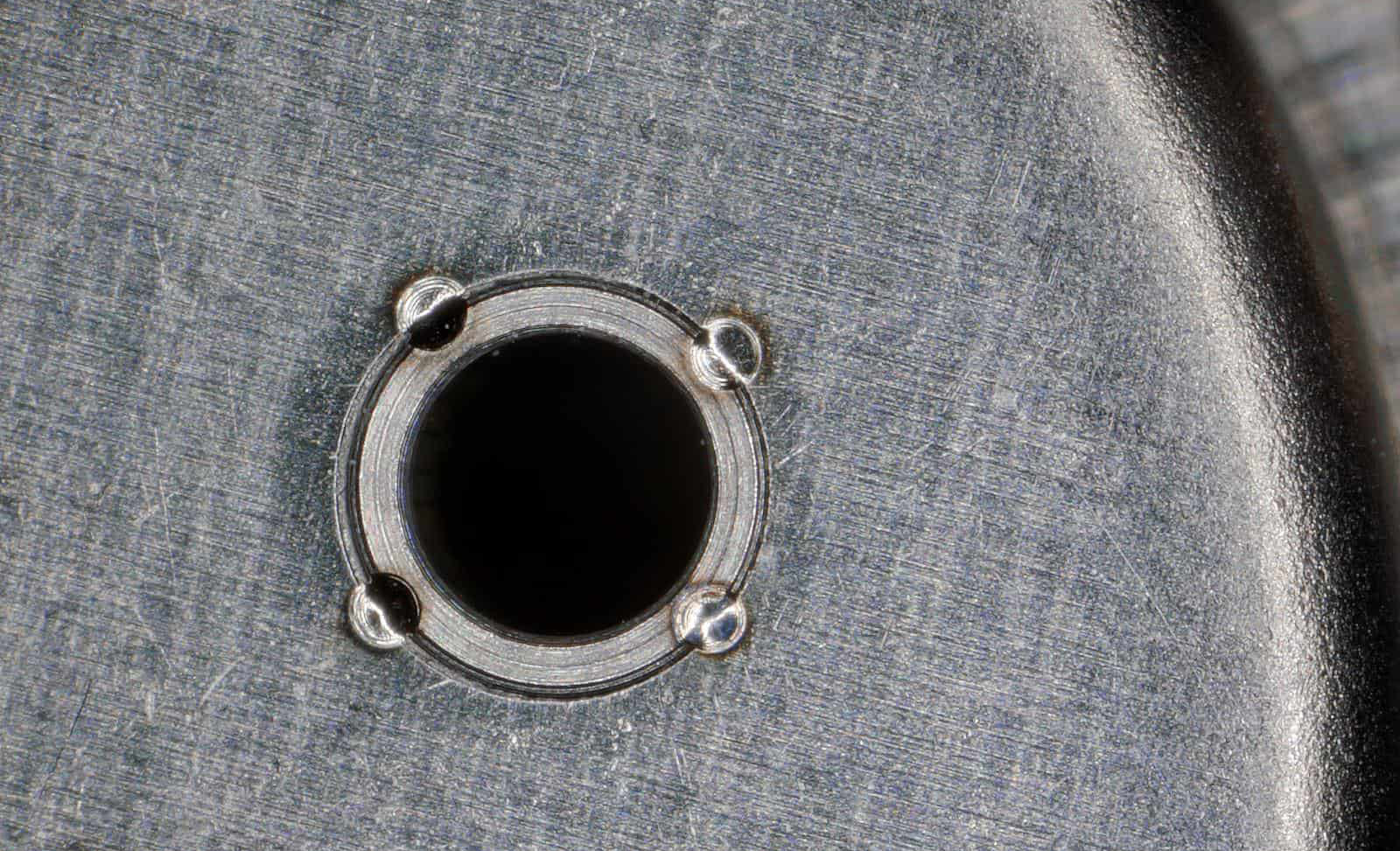

Laser micro welding is a technique that utilizes highly focused laser beams to join materials at a microscopic scale. This process enables the creation of strong, precise welds, often invisible to the naked eye, making it ideal for intricate components and assemblies.

How Does Laser Micro Welding Work?

1. Laser Source Generation

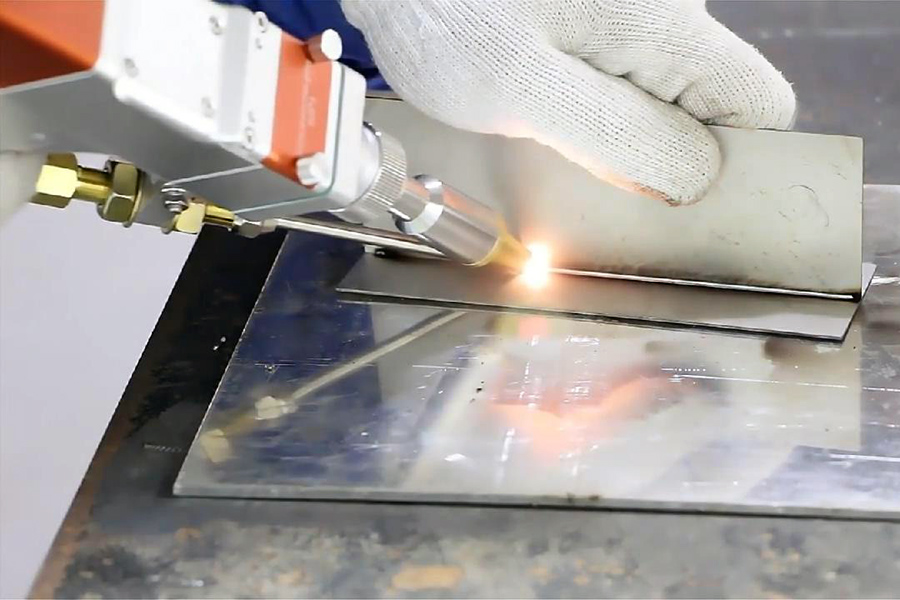

The process begins with a laser source, typically a fiber or pulsed laser, which emits a highly focused beam of light.

2. Beam Focus

The laser beam is directed through optical lenses to concentrate its energy onto a specific point.

3. Heat Application

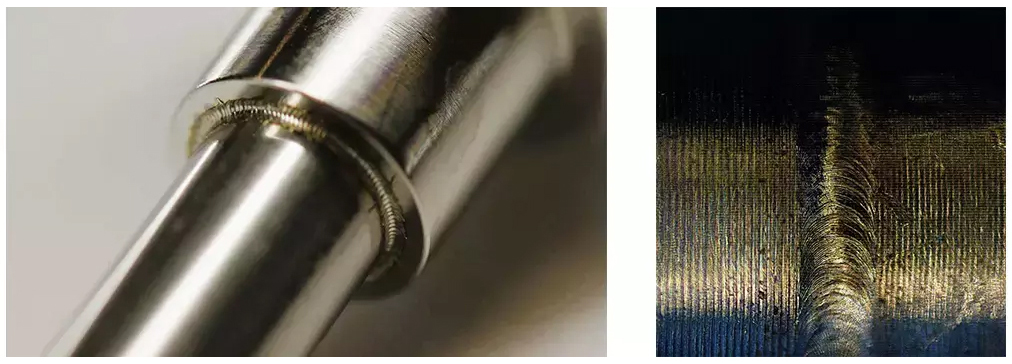

The intense heat generated by the laser melts the material surfaces at the joint, creating a molten pool.

4. Material Fusion

As the molten material cools and solidifies, a strong and seamless weld is formed.

5. Monitoring and Control

Advanced systems monitor parameters such as beam intensity, duration, and focus to ensure consistency.

Key Features of Laser Micro Welding

1. Precision

Laser micro welding achieves sub-micron accuracy, allowing for the creation of delicate and intricate welds.

2. Minimal Heat-Affected Zone (HAZ)

The focused heat minimizes thermal damage to surrounding areas, preserving the integrity of the material.

3. Non-Contact Process

The laser never touches the material, reducing wear and the need for physical tools.

4. Versatility

It works effectively with a wide range of materials, including metals, alloys, and even dissimilar materials.

Applications of Laser Micro Welding

1. Electronics Industry

Used for assembling miniature components like microchips, sensors, and circuit boards.

2. Medical Devices

Enables the production of surgical tools, implants, and other critical devices.

3. Aerospace Engineering

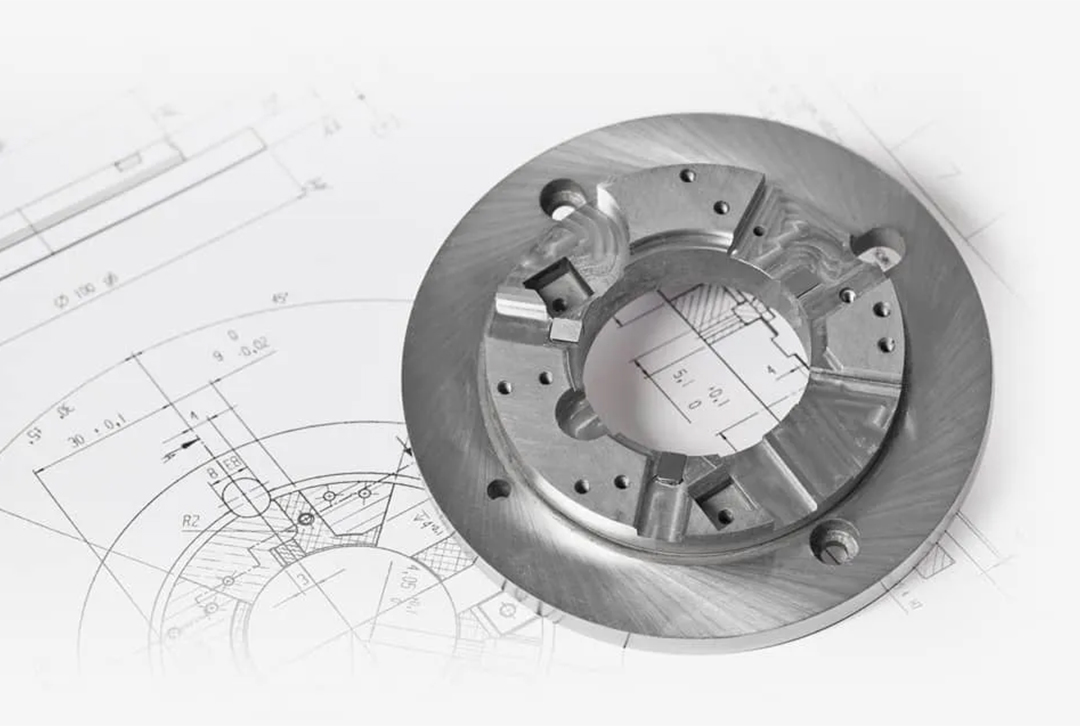

Ideal for creating lightweight, durable components for spacecraft and aircraft.

4. Jewelry and Luxury Goods

Allows for precision repairs and custom designs without visible seams.

5. Automotive Industry

Essential for micro-welding sensors and small parts in modern vehicles.

Benefits of Laser Micro Welding

1. High Strength Welds

Produces welds with superior mechanical properties, ensuring long-lasting performance.

2. Reduced Material Waste

The precision of the process minimizes excess material usage.

3. Increased Productivity

Automated systems allow for faster production cycles without compromising quality.

4. Environmental Friendliness

The process is energy-efficient and produces minimal waste, aligning with sustainable practices.

Challenges in Laser Micro Welding

1. High Initial Costs

The equipment required for laser micro welding can be expensive, though long-term benefits often justify the investment.

2. Operator Training

Specialized skills are needed to operate and maintain the equipment effectively.

3. Material Compatibility

Some materials may require additional preparation or surface treatments to ensure successful welding.

Innovations in Laser Micro Welding

1. AI-Driven Systems

Artificial intelligence is being integrated to optimize weld quality and adjust parameters in real-time.

2. Hybrid Welding Techniques

Combining laser micro welding with other welding methods enhances flexibility and capabilities.

3. Compact and Portable Designs

Newer machines are designed to be smaller and more mobile, increasing accessibility.

4. Advanced Cooling Mechanisms

Improved cooling systems ensure prolonged operation without overheating.

Choosing the Right Laser Micro Welding Machine

1. Application Requirements

Understand the specific needs of your projects, such as material type and weld size.

2. Power and Precision

Select a machine with the appropriate power output and precision capabilities for your applications.

3. Scalability

Choose equipment that can grow with your business and handle increasing demands.

4. Budget Considerations

Balance initial costs with long-term benefits, including maintenance and operational efficiency.

Environmental Impact

Laser micro welding contributes to sustainable manufacturing by reducing energy usage and material waste. Its precision also supports the production of energy-efficient devices and lightweight components.

Future Trends in Laser Micro Welding

1. Advanced Materials

Research is focused on expanding the range of compatible materials, including composites and bio-compatible substances.

2. IoT Integration

The use of IoT in welding machines allows for remote monitoring and diagnostics.

3. Full Automation

Automation continues to enhance productivity and reduce human error in micro welding processes.

4. Cost Reduction

Technological advancements are expected to make laser micro welding more affordable for small and medium enterprises.

Insights for Industry Professionals

For professionals in manufacturing and precision industries, mastering laser micro welding can lead to greater efficiency and innovation. By understanding the capabilities and potential of this technology, businesses can maintain a competitive edge while meeting the growing demands for precision and sustainability.