The Future of Precision Cleaning: An In-Depth Look at Fiber Laser Cleaning

Fiber laser cleaning is reshaping how industries approach surface cleaning and restoration. Combining unparalleled precision, environmental sustainability, and efficiency, it stands as the gold standard for advanced cleaning solutions. This article provides a detailed exploration of fiber laser cleaning technology, its applications, advantages, and the factors to consider when adopting it.

What is Fiber Laser Cleaning?

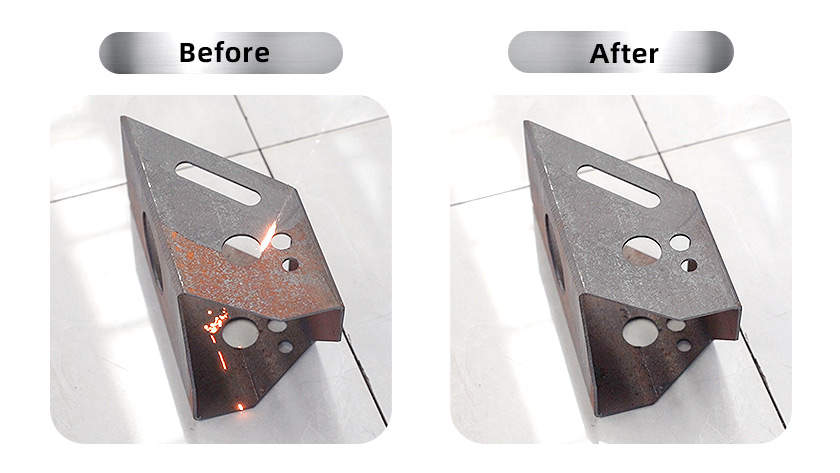

Fiber laser cleaning is an innovative cleaning technology that utilizes high-intensity laser beams to remove contaminants such as rust, paint, oil, and dirt from a wide range of surfaces. Unlike traditional cleaning methods, fiber laser cleaning is non-contact, environmentally friendly, and exceptionally precise.

Key Characteristics

1. Non-Abrasive: Prevents damage to delicate or high-value surfaces.

2. Environmentally Sustainable: Eliminates the need for chemicals or abrasives.

3. High Precision: Cleans specific areas without affecting surrounding materials.

4. Versatile: Suitable for metals, ceramics, and composites.

How Fiber Laser Cleaning Works

The technology operates on the principle of laser ablation, where high-energy laser beams interact with surface contaminants, vaporizing or dislodging them without harming the base material.

The Science Behind It

• Selective Absorption: The laser selectively targets contaminants based on their thermal absorption properties.

• Ablation Process: The high energy breaks down contaminants into vapor or particulates, leaving a clean surface.

Applications of Fiber Laser Cleaning

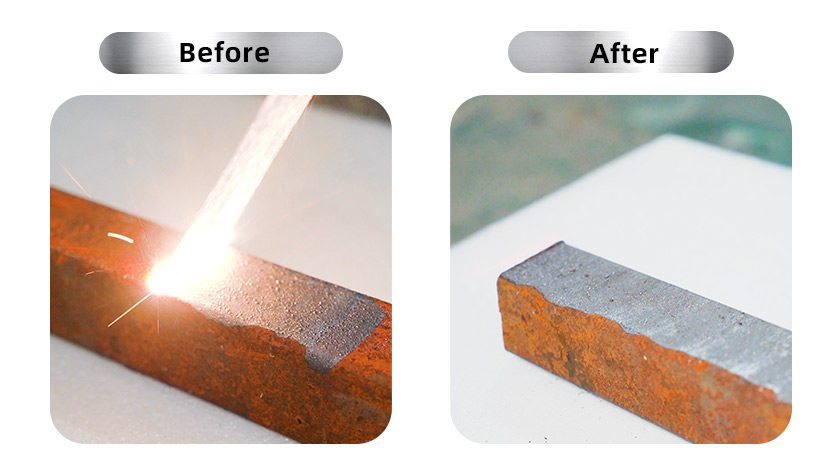

1. Industrial Maintenance

Remove rust, grease, and dirt from machinery to enhance efficiency and extend lifespan.

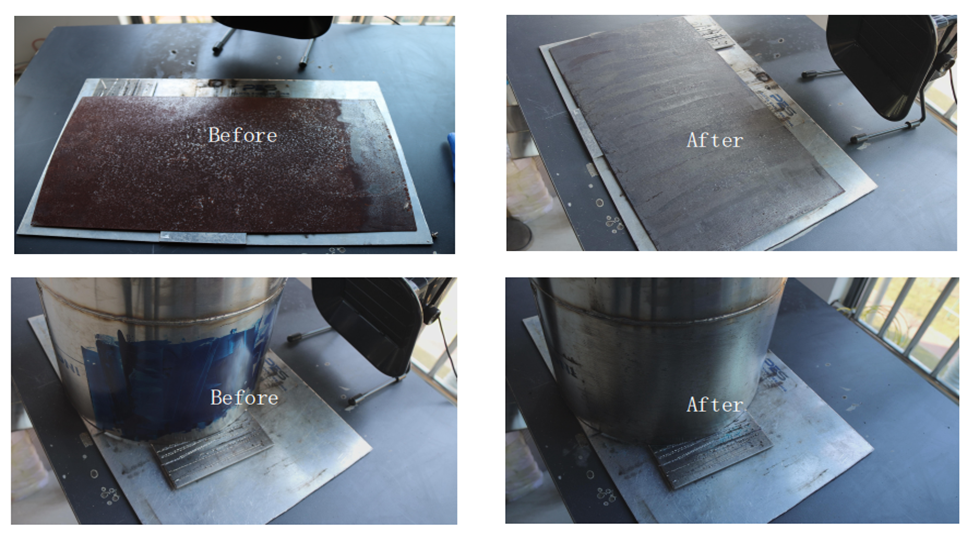

2. Paint and Coating Removal

Effectively strip paint and coatings from vehicles, aircraft, and industrial surfaces without damaging the underlying material.

3. Heritage and Art Conservation

Delicately clean historical artifacts, sculptures, and artworks without causing surface damage.

4. Electronics Manufacturing

Clean sensitive electronic components, ensuring optimal performance without abrasives or chemicals.

5. Surface Preparation

Prepare surfaces for welding, coating, or bonding by removing contaminants and ensuring better adhesion.

Advantages of Fiber Laser Cleaning

1. Environmental Sustainability

• No use of chemicals or abrasives.

• Generates minimal waste, making it eco-friendly.

2. Precision and Control

• Allows for targeted cleaning of specific areas.

• Ideal for delicate or high-value materials.

3. Cost Efficiency

• Reduces the need for consumables and labor.

• Offers long-term savings despite the initial investment.

4. Speed and Efficiency

• Significantly faster than traditional cleaning methods.

• Reduces downtime in industrial operations.

Key Factors to Consider Before Investing in Fiber Laser Cleaning

1. Cleaning Requirements

Identify the materials and contaminants you’ll be working with to ensure compatibility.

2. Power Output

Higher wattage systems provide faster cleaning but may not be necessary for all applications.

3. System Portability

Portable systems are ideal for on-site cleaning, while stationary systems suit factory settings.

4. Cost

Evaluate both upfront costs and long-term savings.

5. After-Sales Support

Ensure the manufacturer offers training, maintenance, and access to spare parts.

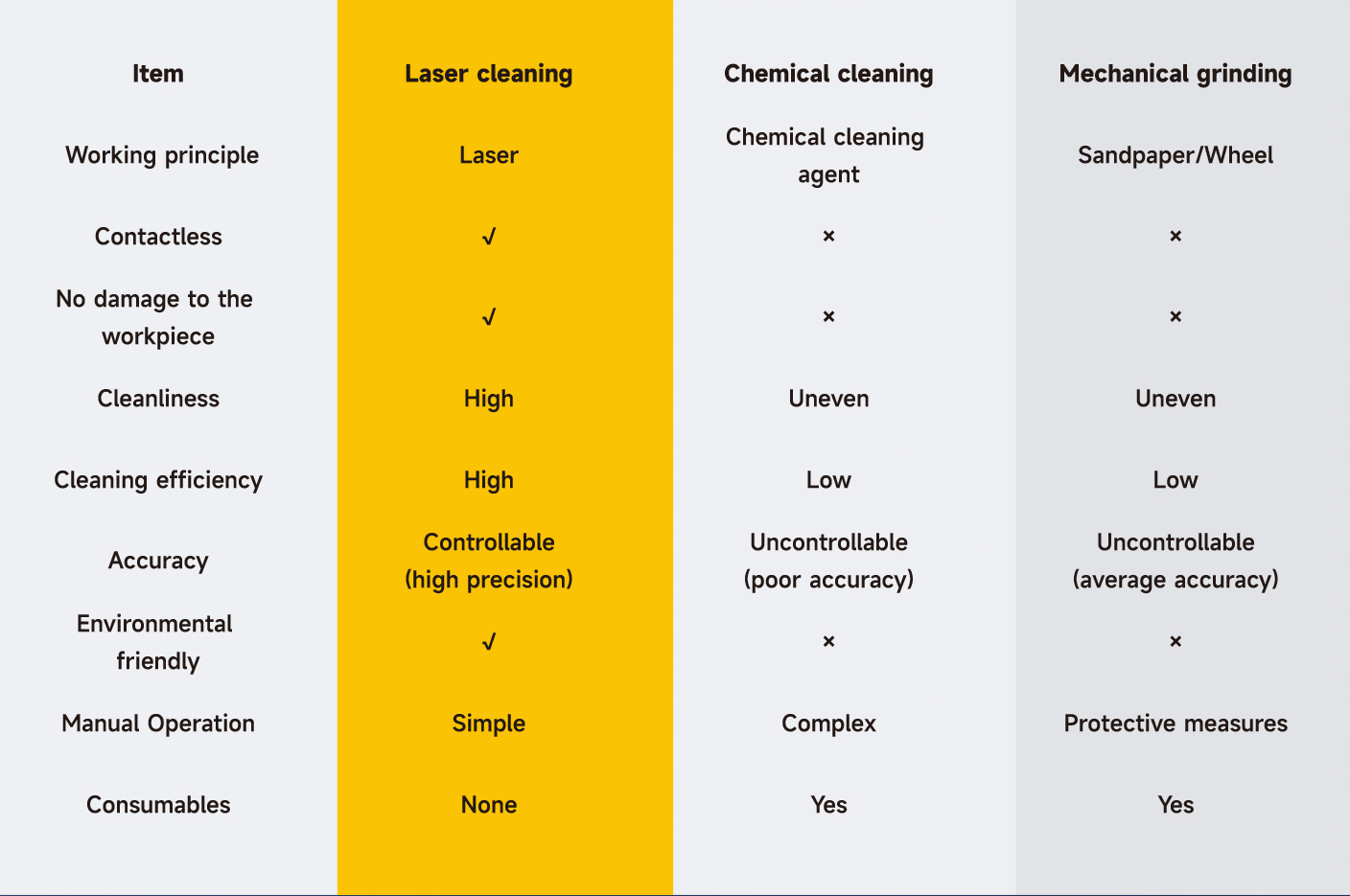

Fiber Laser Cleaning vs Traditional Methods

Chemical Cleaning

• Advantages: Effective for specific contaminants.

• Disadvantages: Harmful to the environment and may damage surfaces.

Abrasive Cleaning

• Advantages: Suitable for large-scale operations.

• Disadvantages: May cause surface damage and generates significant waste.

Fiber Laser Cleaning

• Advantages: Precise, eco-friendly, and efficient.

• Disadvantages: Higher initial cost but superior long-term benefits.

The Cost of Fiber Laser Cleaning Systems

Fiber laser cleaning systems range from $10,000 to $60,000, depending on factors such as power output, features, and design.

Factors Influencing Cost

1. Machine Features: Systems with advanced automation and cooling mechanisms are more expensive.

2. Power Output: Higher wattage systems cost more but offer greater efficiency.

3. Customization: Industry-specific designs often have a premium price.

Hidden Costs

• Training and Installation: Some providers charge separately for these services.

• Maintenance: Routine upkeep ensures optimal performance and longevity.

FAQs About Fiber Laser Cleaning

Q1: Can fiber laser cleaning be used on all materials?

While it is suitable for metals, ceramics, and composites, testing is recommended for sensitive surfaces like wood or fabric.

Q2: Is it safe for operators?

Yes, provided safety guidelines are followed, including wearing protective eyewear.

Q3: What industries benefit most from this technology?

Industries such as automotive, aerospace, electronics, and art restoration benefit significantly.

Q4: How long do these systems last?

With proper maintenance, fiber laser systems can last for over 50,000 operational hours.

Future Trends in Fiber Laser Cleaning Technology

Advancements in fiber laser technology continue to enhance its accessibility and efficiency. Key trends include:

• AI Integration: Automated cleaning systems with adaptive capabilities.

• Compact Designs: Portable systems for on-site applications.

• Cost Reductions: Ongoing innovations are making these systems more affordable.

Why Choose Fiber Laser Cleaning?

Fiber laser cleaning is more than a cleaning method; it is a transformative technology that combines precision, efficiency, and sustainability. Whether for industrial applications or delicate restoration, it offers unmatched advantages over traditional methods, making it an essential tool for modern cleaning solutions.