A Comprehensive Guide to the Best Laser Welding Machine

In an era defined by precision, efficiency, and innovation, finding the best laser welding machine has become essential for industries seeking excellence. From automotive manufacturing to jewelry crafting, laser welding machines deliver unmatched accuracy and performance, revolutionizing modern production techniques. In this guide, we delve into what makes a laser welding machine the best, the key features to look for, and its transformative applications across various sectors.

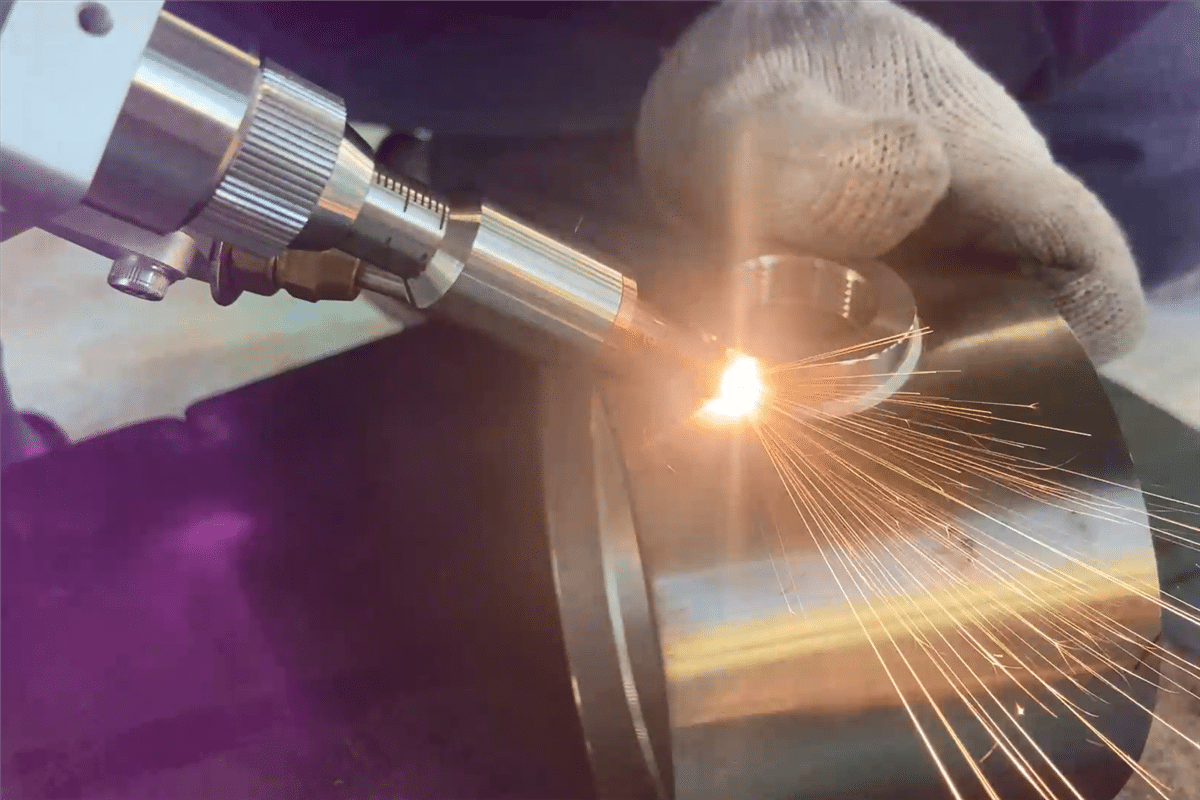

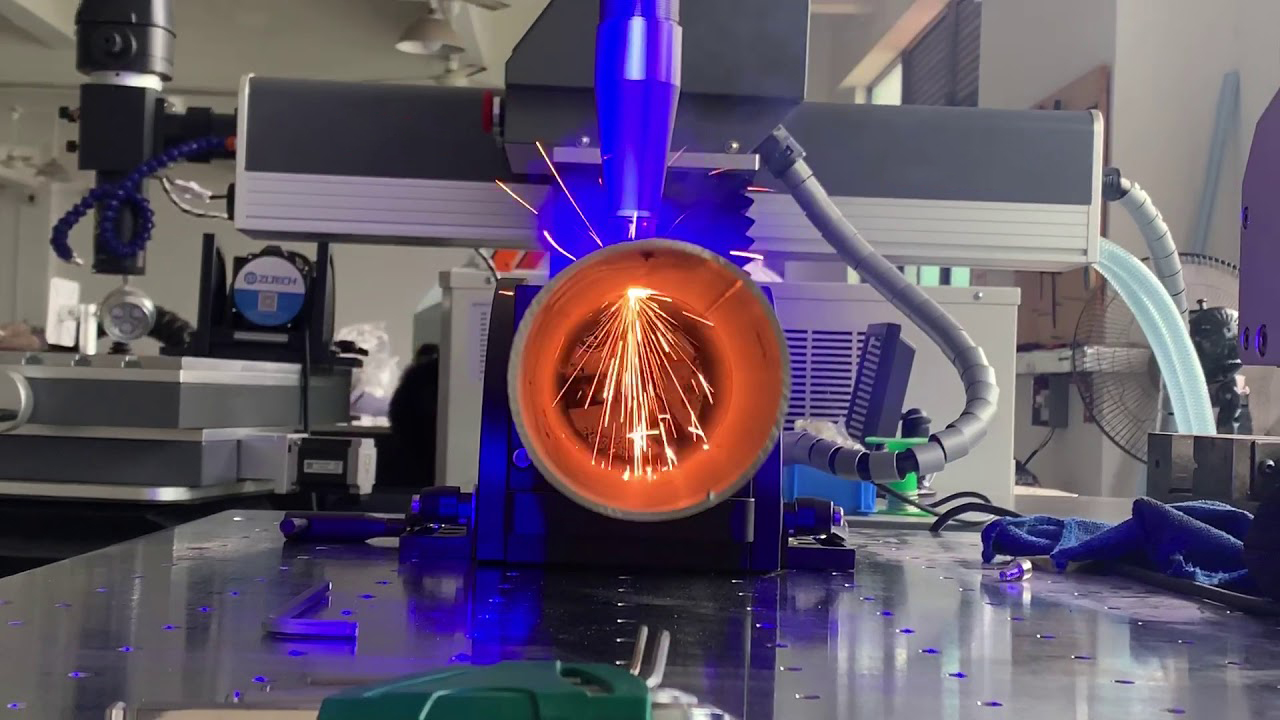

What is a Laser Welding Machine?

A laser welding machine uses focused laser beams to join materials with exceptional precision and minimal thermal impact. This technology offers unparalleled control, making it ideal for complex designs and high-precision applications.

Characteristics of the Best Laser Welding Machine

1. High Precision

Achieving pinpoint accuracy, the best laser welding machines ensure seamless joints without distortion or damage.

2. Versatility

They work efficiently across various materials, including metals, plastics, and even dissimilar materials.

3. Efficiency and Speed

With rapid processing times, these machines significantly enhance production rates.

4. User-Friendly Features

Advanced software interfaces and automation options make these machines accessible to users of varying skill levels.

Key Features to Look for

Power Output

Adjustable power settings ensure compatibility with different material types and thicknesses.

Cooling Systems

Efficient cooling mechanisms prevent overheating and prolong the machine’s lifespan.

Beam Quality

A superior beam profile ensures consistent welds with high strength and minimal defects.

Portability

Compact designs and integrated features allow for easy transportation and operation in various environments.

Industries Transforming with the Best Laser Welding Machines

Automotive

Precision welding enhances the durability and performance of critical components, including body panels and exhaust systems.

Medical Devices

Laser welding is vital for creating high-quality, reliable surgical instruments and implants.

Aerospace

From fuel systems to structural components, aerospace engineering relies on laser welding for safety and efficiency.

Electronics

Delicate circuit boards and micro-components are seamlessly welded, ensuring functionality and durability.

Jewelry and Artistry

Intricate designs are crafted with flawless precision, preserving the aesthetic value of each piece.

How to Choose the Best Laser Welding Machine

Step 1: Define Your Needs

Identify the materials, production scale, and precision requirements for your applications.

Step 2: Evaluate Specifications

Compare features like laser power, wavelength, and beam quality.

Step 3: Assess Durability

Check for robust construction, reliable cooling systems, and minimal maintenance needs.

Step 4: Consult Experts

Seek advice from professionals or experienced users to make an informed decision.

Advantages of Laser Welding Machines

Unparalleled Precision

Delivers accurate welds for intricate designs and tight tolerances.

Environmentally Friendly

Reduces waste and energy consumption compared to traditional welding methods.

Cost-Effective

Though the initial investment is significant, the long-term savings in efficiency and reduced waste justify the cost.

Minimal Heat-Affected Zone

Preserves the material properties and ensures high-quality joints.

Tips for Optimizing Laser Welding Machine Performance

Regular Maintenance

Keep optics clean, inspect electrical connections, and monitor cooling systems for optimal functionality.

Operator Training

Invest in comprehensive training to enhance safety and productivity.

Use Quality Materials

High-quality base materials improve weld strength and appearance.

Upgrade Technology

Adopt the latest software updates and hardware advancements for improved performance.

Future of Laser Welding Machines

Laser welding technology is evolving rapidly, with advancements in AI integration, enhanced automation, and green energy solutions. The best laser welding machine of the future will not only deliver superior performance but also contribute to sustainable manufacturing practices.

This exploration of the best laser welding machine underscores its significance in driving innovation and efficiency across industries. By choosing the right machine and optimizing its use, businesses can achieve remarkable results, ensuring growth and competitiveness in today’s fast-paced world.