Introduction

Imagine a cleaning technology so precise, so efficient, and so eco-friendly that it transforms the way surfaces are restored and contaminants are removed. The pulsed laser cleaning machine is exactly that—a revolutionary solution for industries that demand precision and sustainability. Whether it’s removing rust from metal, stripping paint, or cleaning delicate surfaces, this advanced technology delivers unmatched results. This comprehensive guide explores the technology behind pulsed laser cleaning machines, their applications, and why they are becoming indispensable across industries.

1. What is a Pulsed Laser Cleaning Machine?

A pulsed laser cleaning machine is a device that uses short, high-energy laser pulses to remove contaminants from surfaces without damaging the underlying material. This non-contact cleaning method offers exceptional precision and versatility.

Key Features:

1. Non-Invasive Cleaning: Preserves the integrity of the base material.

2. Eco-Friendly Technology: Eliminates the need for harsh chemicals or abrasive materials.

3. Adaptable Applications: Suitable for metals, plastics, ceramics, and more.

2. How Does a Pulsed Laser Cleaning Machine Work?

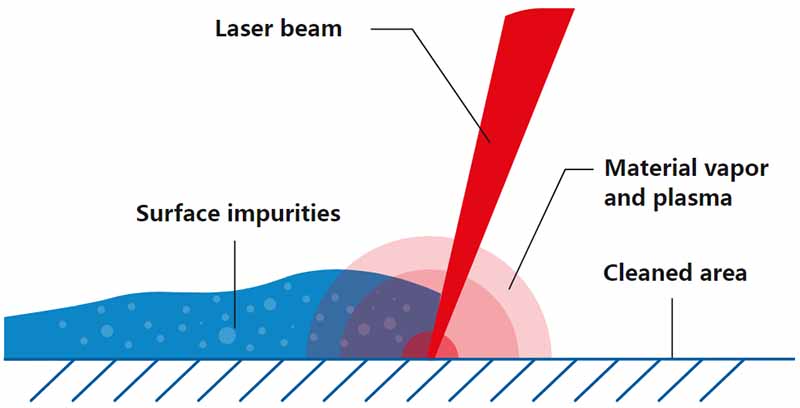

The core technology of pulsed laser cleaning machines relies on laser ablation, where contaminants absorb the laser energy and are vaporized or disintegrated.

Step-by-Step Process:

1. Laser Emission: The machine emits short, intense pulses of laser light.

2. Energy Absorption: Contaminants absorb the laser energy, causing rapid heating.

2. Vaporization: The heat causes contaminants to break apart or vaporize.

3. Clean Surface: The base material remains untouched and residue-free.

Advantages of Pulsed Lasers:

• High Energy Concentration: Enables precise targeting of contaminants.

• Controlled Heat Input: Prevents damage to delicate or heat-sensitive materials.

3. Applications of Pulsed Laser Cleaning Machines

Pulsed laser cleaning machines are highly versatile and are used in various industries for a wide range of applications.

Metal Surface Cleaning

• Removes rust, oil, and oxides from metals.

• Prepares surfaces for welding or coating.

Paint and Coating Removal

• Strips paint without damaging the underlying material.

• Ideal for automotive and aerospace industries.

Restoration of Cultural Artifacts

• Cleans delicate sculptures and paintings without causing damage.

• Removes pollutants and dirt from historical artifacts.

Electronics Manufacturing

• Cleans circuit boards and sensitive electronic components.

• Ensures precision without damaging delicate parts.

Medical Equipment Cleaning

• Sterilizes surgical tools and medical devices.

• Prepares surfaces for high-precision manufacturing.

4. Benefits of Pulsed Laser Cleaning Machines

Unparalleled Precision

• Targets specific contaminants without affecting adjacent areas.

• Suitable for intricate or delicate surfaces.

Eco-Friendly Operation

• No chemicals, abrasives, or secondary waste.

• Reduces environmental impact significantly.

Cost Efficiency

• Low maintenance and operational costs.

• Long-term savings due to reduced consumable usage.

Enhanced Efficiency

• Cleans faster than traditional methods.

• Reduces downtime in industrial applications.

Safety and Reliability

• Non-contact operation minimizes the risk of damage.

• Consistent and repeatable results across applications.

5. Factors to Consider When Choosing a Pulsed Laser Cleaning Machine

Selecting the right machine involves evaluating your specific needs and operational requirements.

Key Considerations:

1. Power Output: Higher power for industrial applications; lower power for precision tasks.

2. Pulse Frequency: Determines the cleaning speed and precision.

3. Portability: Handheld machines for on-site cleaning; stationary systems for factory use.

4. Safety Features: Look for features like enclosures and emergency shut-offs.

5. Material Compatibility: Ensure the machine can handle the materials you work with.

Example Use Case:

An aerospace company cleaning turbine components can benefit from a high-power pulsed laser cleaning machine for efficient and precise results.

6. Price Ranges for Pulsed Laser Cleaning Machines

The cost of pulsed laser cleaning machines varies depending on their specifications and features.

Entry-Level Machines:

• Price Range: $8,000 – $15,000

• Features: Suitable for small-scale projects or personal use.

Mid-Range Machines:

• Price Range: $15,000 – $30,000

• Features: Ideal for medium-sized industrial applications.

High-End Machines:

• Price Range: $30,000+

• Features: Designed for large-scale or highly specialized tasks.

7. Comparing Pulsed Laser Cleaning Machines to Traditional Methods

Traditional Methods:

• Chemical Cleaning: Risk of residue and environmental harm.

• Abrasive Techniques: Potential to damage sensitive surfaces.

• Manual Scrubbing: Labor-intensive with inconsistent results.

Pulsed Laser Cleaning:

• Non-contact and residue-free.

• Environmentally sustainable with no harmful byproducts.

• Faster and more precise than conventional cleaning methods.

8. Frequently Asked Questions About Pulsed Laser Cleaning Machines

Q1: Are pulsed laser cleaning machines safe?

Yes, modern machines come with safety features to protect operators and ensure safe use.

Q2: Can these machines clean all materials?

They are suitable for a wide range of materials, but settings must be adjusted for optimal results.

Q3: How much maintenance do these machines require?

Minimal maintenance is needed compared to traditional cleaning equipment.

Q4: Can pulsed laser cleaning machines be automated?

Yes, many systems can be integrated with robotic arms for fully automated cleaning processes.

Final Thoughts

Pulsed laser cleaning machines are setting new standards for surface cleaning with their precision, efficiency, and eco-friendly operation. From industrial applications to cultural restoration, their versatility and effectiveness make them a valuable investment for businesses and professionals alike. Understanding their capabilities and selecting the right system can revolutionize cleaning processes and improve operational outcomes across industries. Explore the possibilities and transform your approach to surface cleaning with this advanced technology.