Introduction

The phrase “laser wood cleaning machine price” might evoke questions about affordability, innovation, and practicality. In a world driven by technology, laser wood cleaning machines stand out as eco-friendly, efficient, and precise tools for surface cleaning. Whether you’re restoring antique furniture, cleaning intricate wooden artifacts, or preparing wood for further processing, understanding the price of laser wood cleaning machines is crucial for making informed decisions. This comprehensive guide will unravel everything you need to know about pricing, features, and factors influencing costs, helping you invest wisely.

1. What is a Laser Wood Cleaning Machine?

A laser wood cleaning machine is a specialized device designed to clean and restore wooden surfaces using laser technology. Unlike traditional methods that may harm the wood, laser cleaning ensures precision and preserves the material’s integrity.

Key Features:

1. Non-Destructive Process: Cleans without damaging the wood grain.

2. Eco-Friendly: No chemicals or abrasives are required.

3. Versatility: Suitable for antiques, furniture, and industrial applications.

Why It Matters:

• Offers sustainable solutions for wood restoration.

• Minimizes labor and maintenance costs in the long run.

2. How Does Laser Wood Cleaning Work?

Laser cleaning involves using a focused beam of light to vaporize contaminants such as dirt, paint, or old coatings from wooden surfaces. The process is safe, precise, and efficient.

Step-by-Step Process:

1. Laser Emission: A concentrated laser beam is directed at the surface.

2. Contaminant Absorption: The laser’s energy is absorbed by the dirt or coating.

3. Vaporization: Heat from the laser vaporizes the contaminants.

4. Clean Surface: The wood beneath remains intact and undamaged.

Technical Insights:

• Adjustable Power Settings: Tailored for different types of wood and contamination levels.

• Beam Precision: Ensures delicate surfaces remain unharmed.

3. Factors Influencing Laser Wood Cleaning Machine Prices

Understanding the price of a laser wood cleaning machine involves examining various factors that contribute to its cost.

Machine Specifications:

1. Laser Power: Higher power models are more expensive but clean faster.

2. Size and Portability: Compact designs may cost less but have limited applications.

Features and Accessories:

• Advanced Controls: Machines with digital interfaces and custom settings are pricier.

• Safety Features: Built-in protective measures add to the cost.

Intended Use:

1. Industrial Applications: Machines for large-scale cleaning are more expensive.

2. Personal or Small-Scale Use: Lower-cost options for occasional cleaning.

Brand and Warranty:

• Reliable manufacturers often charge more but provide better support and warranties.

4. Price Ranges for Laser Wood Cleaning Machines

Laser wood cleaning machines come in various price ranges, catering to different needs and budgets.

Entry-Level Machines:

• Price Range: $3,000 – $8,000

• Features: Suitable for small projects and personal use.

Mid-Range Machines:

• Price Range: $8,000 – $20,000

• Features: Ideal for medium-scale operations with adjustable settings.

High-End Machines:

• Price Range: $20,000+

• Features: Designed for industrial applications, offering advanced technology and higher power.

5. Applications of Laser Wood Cleaning Machines

Laser wood cleaning machines are versatile tools used across various industries and settings.

Restoration of Antiques

• Removes dirt and old finishes without harming delicate wood carvings.

• Preserves the original texture and color of historic pieces.

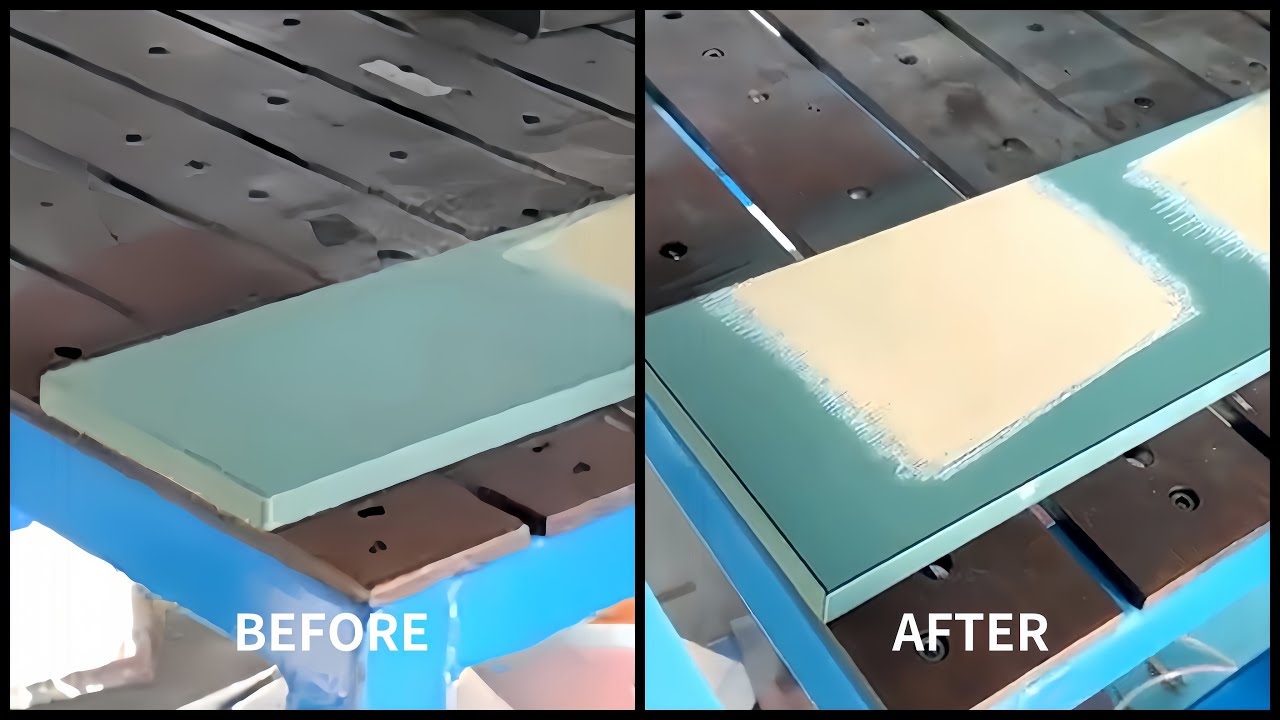

Furniture Refinishing

• Prepares furniture for new coatings or stains.

• Strips old varnish efficiently without sanding.

Industrial Use

• Cleans wooden surfaces in factories and workshops.

• Prepares wood for laminations or adhesive applications.

Art and Craft

• Restores wooden sculptures and intricate designs.

• Ideal for artists and artisans working with wood.

6. Benefits of Laser Wood Cleaning Machines

Precision Cleaning

• Targets specific areas without affecting the surrounding material.

• Perfect for detailed or intricate surfaces.

Eco-Friendly Operation

• No chemicals or abrasive materials are used.

• Produces no secondary waste, reducing environmental impact.

Cost Efficiency

• Low maintenance and operational costs.

• Long-term savings due to reduced labor and consumable use.

Time-Saving

• Faster than traditional cleaning methods.

• Reduces downtime in industrial settings.

7. How to Choose the Right Laser Wood Cleaning Machine

Selecting the right machine involves assessing your needs and budget.

Key Considerations:

1. Purpose: Determine whether you need the machine for personal, commercial, or industrial use.

2. Power Requirements: Higher power is ideal for industrial applications; lower power suffices for small projects.

3. Portability: Choose a portable model for on-site work or a stationary one for workshop use.

4. Budget: Balance your needs with your budget to find the best value.

8. Common Questions About Laser Wood Cleaning Machines

Q1: Are laser wood cleaning machines worth the investment?

Yes, their efficiency, precision, and eco-friendliness make them a valuable long-term investment.

Q2: How much maintenance is required?

Minimal maintenance is needed compared to traditional cleaning equipment.

Q3: Can laser cleaning damage wood?

No, when used correctly, laser cleaning preserves the wood’s integrity while removing contaminants.

Q4: How do I know if a machine is right for my needs?

Assess your cleaning requirements, budget, and desired features to make an informed choice.

Final Thoughts

Laser wood cleaning machines combine innovation, efficiency, and sustainability to transform how wooden surfaces are cleaned and restored. While the initial price might seem high, the long-term savings in labor, materials, and time make them a worthwhile investment. Whether you’re restoring antiques, refinishing furniture, or working on industrial wood cleaning projects, understanding the pricing and features will help you choose the best machine for your needs.