Laser Wood Cleaner: Transforming the Way We Maintain Wooden Surfaces

The laser wood cleaner is more than a cleaning tool—it’s a technological breakthrough. Imagine restoring wooden surfaces with unmatched precision, eliminating dirt, paint, or contaminants without damaging the wood. Whether you’re a professional in woodworking or an enthusiast preserving antique furniture, understanding the capabilities of a laser wood cleaner is essential.

Understanding Laser Wood Cleaning Technology

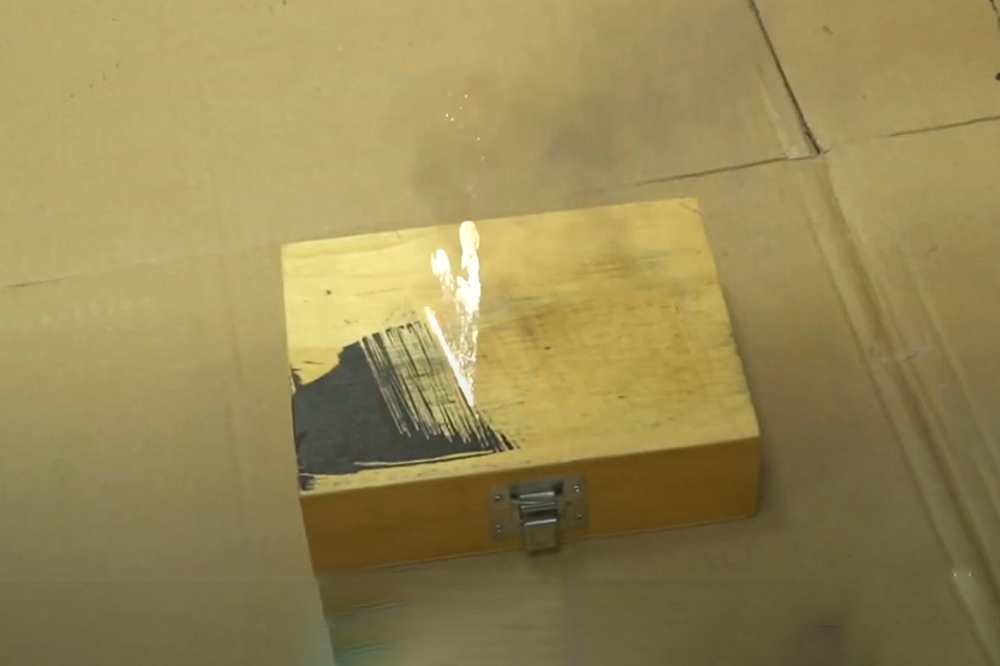

Laser wood cleaning employs advanced laser beams to vaporize dirt, residues, or coatings from wooden surfaces. This process, known as laser ablation, is non-abrasive and ensures the preservation of the wood’s natural beauty.

How It Works

1. Laser Emission: Focused laser pulses target the contaminated area.

2. Contaminant Absorption: Dirt or coatings absorb the laser energy, breaking down molecular bonds.

3. Vaporization: The unwanted layer is vaporized or sublimated, leaving a clean wooden surface.

Advantages of Using a Laser Wood Cleaner

1. Preservation of Wood Integrity

Unlike chemical or abrasive methods, laser cleaning avoids scraping or scratching, maintaining the wood’s structure and texture.

2. Eco-Friendly Process

Laser wood cleaners do not rely on solvents or chemicals, making them a green alternative for surface cleaning.

3. Precise Cleaning

The targeted laser beam ensures only the required area is cleaned, leaving the rest of the surface untouched.

4. Versatility

From restoring antique furniture to cleaning large wooden panels, laser cleaners adapt to various wooden surfaces and conditions.

5. Time and Cost Efficiency

Although the initial investment in a laser cleaner may be high, the reduced labor, consumables, and maintenance costs make it a long-term cost-effective solution.

Applications of Laser Wood Cleaners

1. Restoration of Antique Furniture

Remove decades of grime or old coatings while preserving delicate wood details.

2. Cleaning Wooden Floors

Effectively clean hardwood floors without damaging their finish.

3. Removing Paint and Coatings

Strip paint layers or coatings from wooden surfaces, preparing them for refinishing.

4. Conservation Projects

Used in museums or archaeological sites to clean and preserve historical wooden artifacts.

Factors Influencing the Price of a Laser Wood Cleaner

1. Power Output

Higher power levels ensure faster cleaning but come at a premium cost.

2. Machine Features

Advanced features like automation, portability, and precision control increase the price.

3. Application Type

Specialized models tailored for unique wooden surfaces may cost more.

4. Maintenance and Support

Reliable customer support and warranties can add to the upfront investment.

Comparison: Laser Wood Cleaning vs. Traditional Methods

| Feature | Laser Wood Cleaner | Traditional Methods |

|---|---|---|

| Surface Preservation | Excellent | Moderate to poor |

| Chemical Usage | None | High |

| Environmental Impact | Minimal | Significant |

| Precision | High | Limited |

| Time Efficiency | High | Variable |

Recent Advancements in Laser Wood Cleaners

1. AI Integration

Laser wood cleaners now feature artificial intelligence for better surface recognition and optimal cleaning performance.

2. Portable Models

Compact designs have made laser cleaners more accessible for on-site and home use.

3. Enhanced Energy Efficiency

Modern lasers consume less energy while maintaining superior cleaning power.

4. Improved Safety Measures

Innovations include enhanced safety interlocks and intuitive controls, reducing operational risks.

How to Select the Right Laser Wood Cleaner

1. Define Cleaning Needs: Assess the type of wooden surfaces and the level of cleaning required.

2. Budget Considerations: Weigh the upfront cost against the expected long-term savings.

3. Evaluate Features: Look for features like automation, portability, and user-friendly interfaces.

4. Research Maintenance Costs: Ensure the machine is easy to maintain and comes with reliable support.

5. Request Demonstrations: Test the cleaner on actual wooden surfaces to validate its performance.

FAQs About Laser Wood Cleaners

Q: Can laser wood cleaners be used on delicate wooden artifacts?

Yes, laser wood cleaners are designed to clean delicate surfaces without causing any damage.

Q: Are laser wood cleaners safe for indoor use?

Yes, they are safe, provided proper ventilation and safety protocols are followed.

Q: How does laser cleaning compare to sandblasting for wood?

Laser cleaning is more precise, non-abrasive, and environmentally friendly compared to sandblasting.

The Role of Laser Wood Cleaners in Sustainable Practices

As industries and individuals prioritize sustainability, laser wood cleaners have emerged as a frontrunner. By eliminating the need for harmful chemicals and reducing waste, they align with global efforts toward eco-friendly practices. Whether restoring antiques or cleaning modern wooden installations, investing in a laser wood cleaner ensures precision, efficiency, and environmental responsibility.