Revolutionizing Manufacturing: Laser Welding Stainless Steel

Laser welding stainless steel has transformed how industries approach metal joining, offering unparalleled precision, efficiency, and versatility. This article delves deep into the mechanics, applications, and benefits of this cutting-edge technology, showcasing why it’s the go-to solution for manufacturers worldwide.

Understanding the Process of Laser Welding Stainless Steel

At its core, laser welding stainless steel uses a high-powered laser beam to fuse metal surfaces together. This method is precise, non-contact, and ideal for intricate designs or high-strength joints.

Key Components of Laser Welding Systems

1. Laser Source: Typically a fiber or CO2 laser.

2. Optical System: Directs the laser beam onto the stainless steel surface.

3. Cooling System: Maintains the system’s optimal temperature.

How It Works

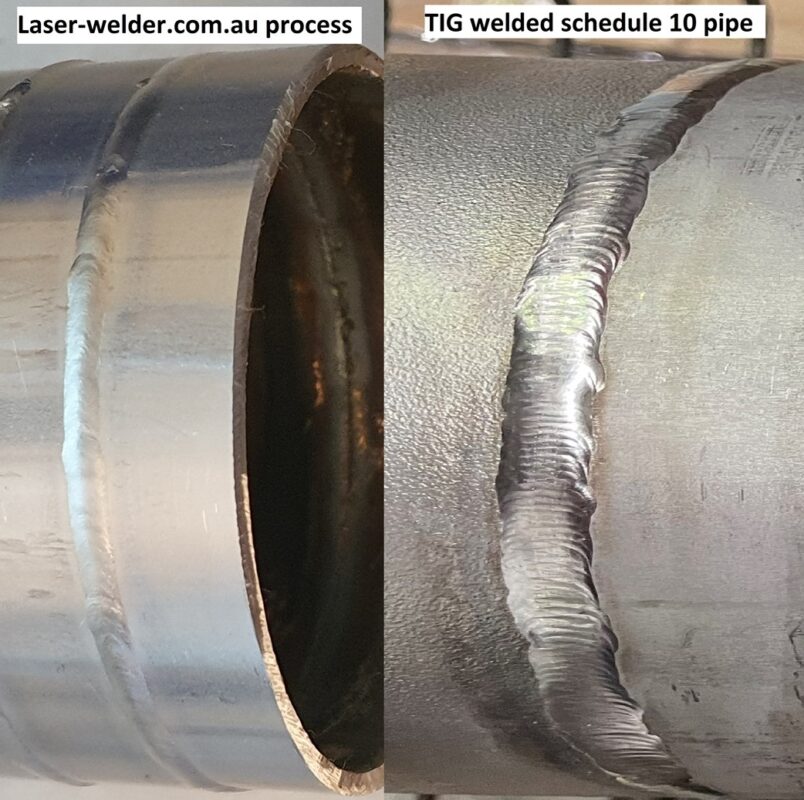

The laser heats the stainless steel, creating a molten pool that solidifies to form a seamless joint. This method minimizes thermal distortion and produces exceptionally clean welds.

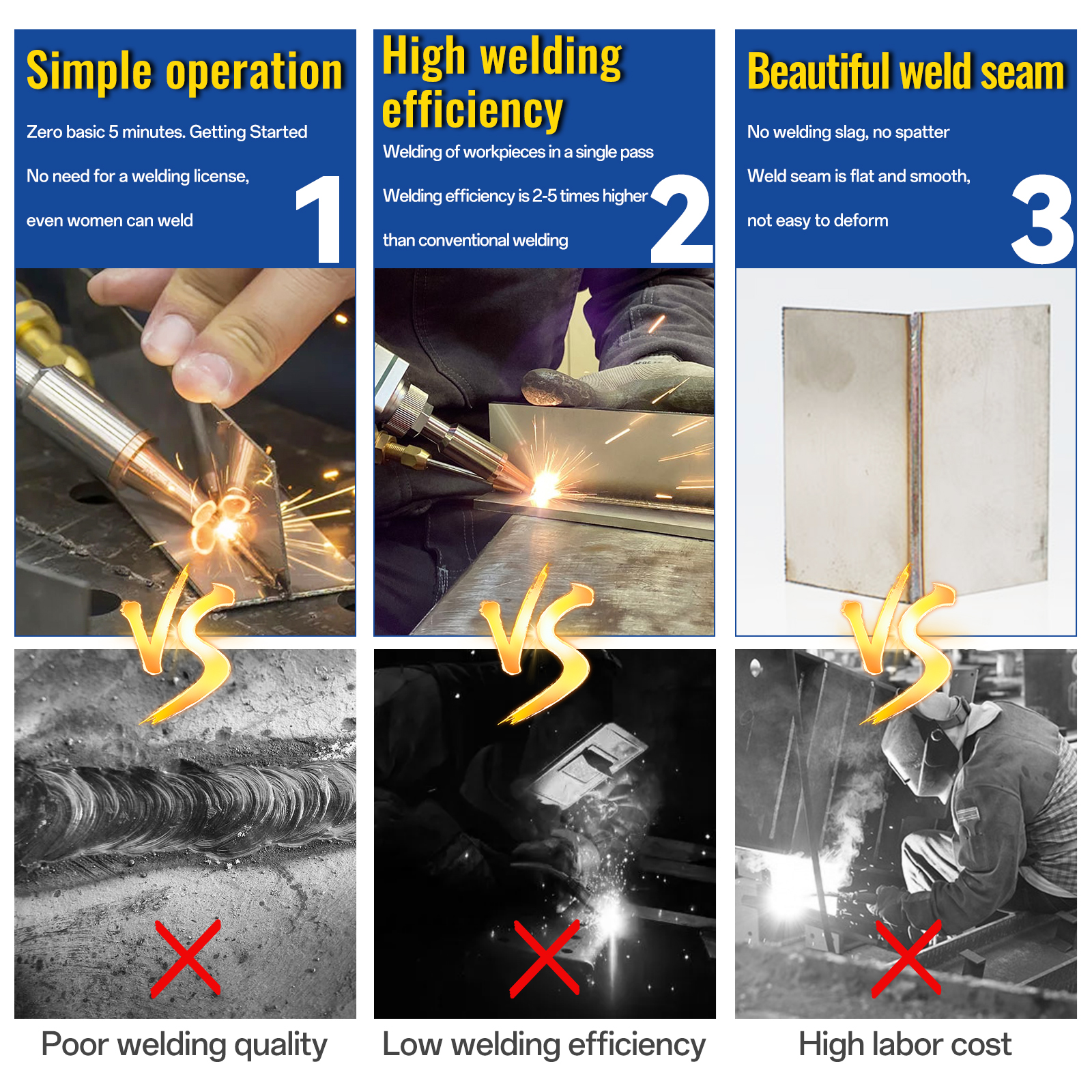

Benefits of Laser Welding Stainless Steel

1. Precision and Cleanliness

Laser welding offers unparalleled accuracy, reducing the need for post-weld finishing.

2. Minimal Heat-Affected Zone (HAZ)

The focused laser beam ensures heat is localized, preserving the integrity of the surrounding material.

3. Versatility

Stainless steel of varying thicknesses can be welded, from ultra-thin foils to heavy plates.

4. Speed and Efficiency

With rapid heating and cooling cycles, laser welding accelerates production timelines.

5. Eco-Friendly

The process generates less waste and energy consumption compared to traditional welding methods.

Applications of Laser Welding Stainless Steel

1. Automotive Industry

From exhaust systems to battery enclosures, stainless steel components are laser-welded for durability and precision.

2. Medical Devices

Surgical instruments and implants often require the clean, biocompatible welds that only laser welding can deliver.

3. Food and Beverage Equipment

Stainless steel’s corrosion resistance makes it a favorite in hygienic applications, with laser welding ensuring smooth, bacteria-free joints.

4. Aerospace Engineering

High-performance stainless steel parts, critical for safety and reliability, are often laser-welded for structural integrity.

5. Electronics

Thin stainless steel sheets in devices like sensors and connectors benefit from the precision of laser welding.

Optimizing Laser Welding for Stainless Steel

Material Preparation

Cleaning the surface of stainless steel before welding is crucial to avoid contamination.

Parameter Settings

The right power, speed, and focus adjustments ensure optimal weld quality.

Advanced Techniques

• Keyhole Welding: For deeper penetration.

• Conduction Welding: For surface-level joins.

Post-Weld Treatments

Polishing and passivation enhance the appearance and longevity of stainless steel welds.

Challenges and Solutions

1. Reflectivity of Stainless Steel

Solution: Use beam absorbers or adjust laser parameters for consistent penetration.

2. Thermal Expansion

Solution: Optimize cooling systems to mitigate warping.

3. High Initial Costs

Solution: Focus on long-term savings from reduced waste and faster production cycles.

Innovations in Laser Welding Stainless Steel

1. Hybrid Welding Techniques

Combining laser and arc welding for enhanced flexibility and strength.

2. AI Integration

Real-time monitoring and parameter adjustments ensure consistent weld quality.

3. Portable Laser Welders

Enabling on-site welding for large or immovable stainless steel structures.

4. Green Laser Technology

Enhanced absorption of stainless steel surfaces reduces energy requirements.

How to Select the Best Laser Welding System

1. Define Your Requirements

Understand the thickness, application, and desired weld quality for your stainless steel project.

2. Compare Laser Types

• Fiber Lasers: Best for precision and thin materials.

• CO2 Lasers: Ideal for thicker stainless steel.

3. Evaluate Automation Options

Consider robotic systems for repetitive tasks and complex geometries.

4. Assess Long-Term Value

Balance upfront costs with operational savings and production efficiency.

Laser welding stainless steel has redefined the standards of precision and durability in manufacturing. By understanding the process, leveraging advanced techniques, and staying updated on industry innovations, businesses can unlock the full potential of this transformative technology.