Laser Surface Cleaner: Redefining Precision and Efficiency in Cleaning Technology

The laser surface cleaner is not just a tool—it’s a revolution. Imagine cleaning surfaces with unparalleled precision, efficiency, and sustainability, all without chemicals or abrasive materials. Whether you’re an industrial professional or an enthusiast exploring advanced technologies, understanding the potential of a laser surface cleaner is crucial.

What Is a Laser Surface Cleaner?

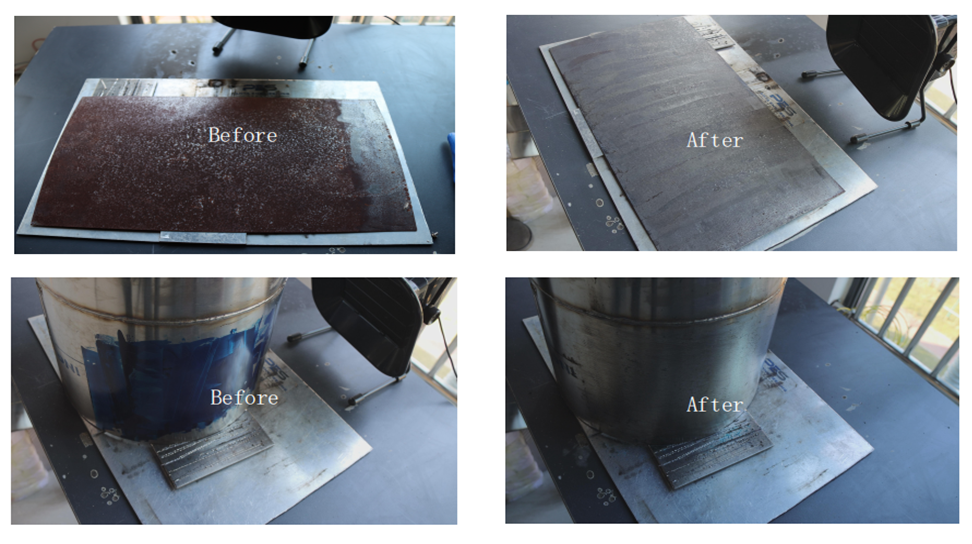

A laser surface cleaner uses concentrated laser beams to remove rust, dirt, paint, and other contaminants from surfaces without causing damage to the base material. It is a non-contact, non-abrasive method that has gained significant traction across industries for its efficiency and eco-friendly approach.

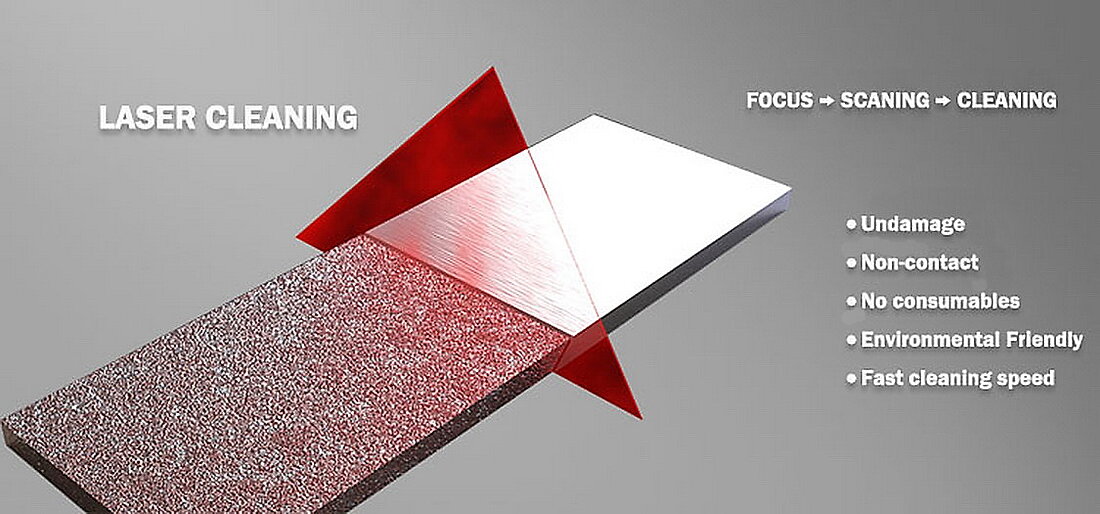

How Does Laser Surface Cleaning Work?

Laser cleaning operates on the principle of laser ablation, where contaminants are vaporized upon exposure to high-energy laser pulses. The process involves:

1. Emission of Laser Pulses: Focused laser beams are directed at the contaminated surface.

2. Absorption of Energy: Contaminants absorb the laser energy, breaking molecular bonds.

3. Evaporation or Sublimation: The contaminants are vaporized or sublimated, leaving the surface clean.

Advantages of Using a Laser Surface Cleaner

1. Non-Abrasive and Contact-Free

Unlike traditional methods, laser cleaning does not wear down or damage the base material, making it ideal for delicate surfaces.

2. Environmentally Friendly

Laser cleaning eliminates the need for chemicals, solvents, or water, significantly reducing environmental impact.

3. High Precision

The focused laser beam ensures that only the targeted area is cleaned, preserving surrounding materials.

4. Versatility

From industrial equipment to delicate artifacts, laser surface cleaners adapt to various applications.

5. Cost Efficiency

While the initial investment may seem high, the long-term savings on consumables and maintenance outweigh the costs.

Factors Affecting the Price of a Laser Surface Cleaner

Understanding the cost dynamics of laser surface cleaners can help you make an informed investment.

1. Power Output

Laser power ranges from 20W for light cleaning to over 1000W for industrial applications. Higher power levels result in faster cleaning but come with higher prices.

2. Automation and Features

Machines with automated settings, AI integration, and user-friendly interfaces typically cost more.

3. Portability

Compact and portable designs add convenience but may increase the cost.

4. Application Type

Specialized models designed for niche applications often come at a premium.

5. Warranty and Support

Comprehensive warranties and after-sales support contribute to the overall price.

Applications of Laser Surface Cleaners

1. Automotive Industry

Remove rust and coatings from car frames and parts efficiently.

2. Aerospace Sector

Ensure precision cleaning of sensitive components like turbine blades.

3. Manufacturing and Fabrication

Maintain machinery by removing contaminants like grease, rust, and residues.

4. Heritage Preservation

Restore historical artifacts without compromising their integrity.

5. Marine Industry

Clean ship hulls and marine equipment to prevent corrosion.

Comparison: Laser Surface Cleaning vs. Traditional Methods

| Aspect | Laser Surface Cleaning | Traditional Methods |

|---|---|---|

| Precision | High | Moderate |

| Chemical Usage | None | High |

| Environmental Impact | Minimal | High |

| Surface Damage | None | Possible |

| Speed | High | Variable |

Technological Advancements in Laser Surface Cleaners

1. AI-Driven Systems

Advanced laser cleaners adapt automatically to different surfaces, enhancing efficiency.

2. Compact and Portable Designs

Portable models offer flexibility for on-site cleaning tasks.

3. Improved Energy Efficiency

Modern machines consume less energy while delivering high performance.

4. Enhanced Safety Features

Safety interlocks and user-friendly interfaces reduce risks.

How to Choose the Right Laser Surface Cleaner

1. Assess Cleaning Requirements: Determine the type and scale of cleaning tasks.

2. Evaluate Budget: Consider the initial cost versus long-term savings.

3. Check Specifications: Ensure the machine’s power and features match your needs.

4. Request a Demo: Test the cleaner on actual surfaces to verify performance.

5. Review After-Sales Support: Opt for suppliers offering reliable warranties and maintenance.

FAQs About Laser Surface Cleaners

Q: Are laser surface cleaners suitable for delicate surfaces?

Yes, they can clean delicate surfaces without causing damage, thanks to their precision.

Q: What maintenance is required for a laser cleaner?

Minimal maintenance is needed; regular inspections and cleaning of optical components are sufficient.

Q: Can laser surface cleaners handle large-scale cleaning tasks?

High-power models are designed for industrial-scale applications, offering fast and efficient cleaning.

The Future of Laser Surface Cleaning

As industries prioritize sustainability and precision, laser surface cleaners will continue to gain prominence. Their ability to deliver unparalleled results without harming the environment positions them as a critical tool in modern cleaning technology. Whether you’re looking to invest for industrial use or smaller-scale applications, understanding the nuances of laser surface cleaners ensures you maximize their potential.