Laser Cutting Welding Machine: A Game-Changer in Manufacturing

The laser cutting welding machine represents a quantum leap in manufacturing technology. Combining unparalleled precision, efficiency, and versatility, this innovative tool is redefining industrial standards across the globe. From intricate designs to robust joints, the potential of laser cutting welding machines is transforming industries.

What Is a Laser Cutting Welding Machine?

A laser cutting welding machine merges two critical processes: cutting and welding, into one efficient system. It uses a high-energy laser beam to cut through materials with precision, followed by welding operations to join components seamlessly.

How Does It Work?

Laser Cutting

The machine focuses a laser beam onto the material, vaporizing it and creating clean, precise cuts with minimal waste.

Laser Welding

After cutting, the same system welds components by melting the interface of two materials, forming a strong and durable bond.

Why Choose a Laser Cutting Welding Machine?

Precision and Accuracy

Laser technology allows for micron-level precision, making it ideal for intricate designs and detailed work.

Efficiency and Speed

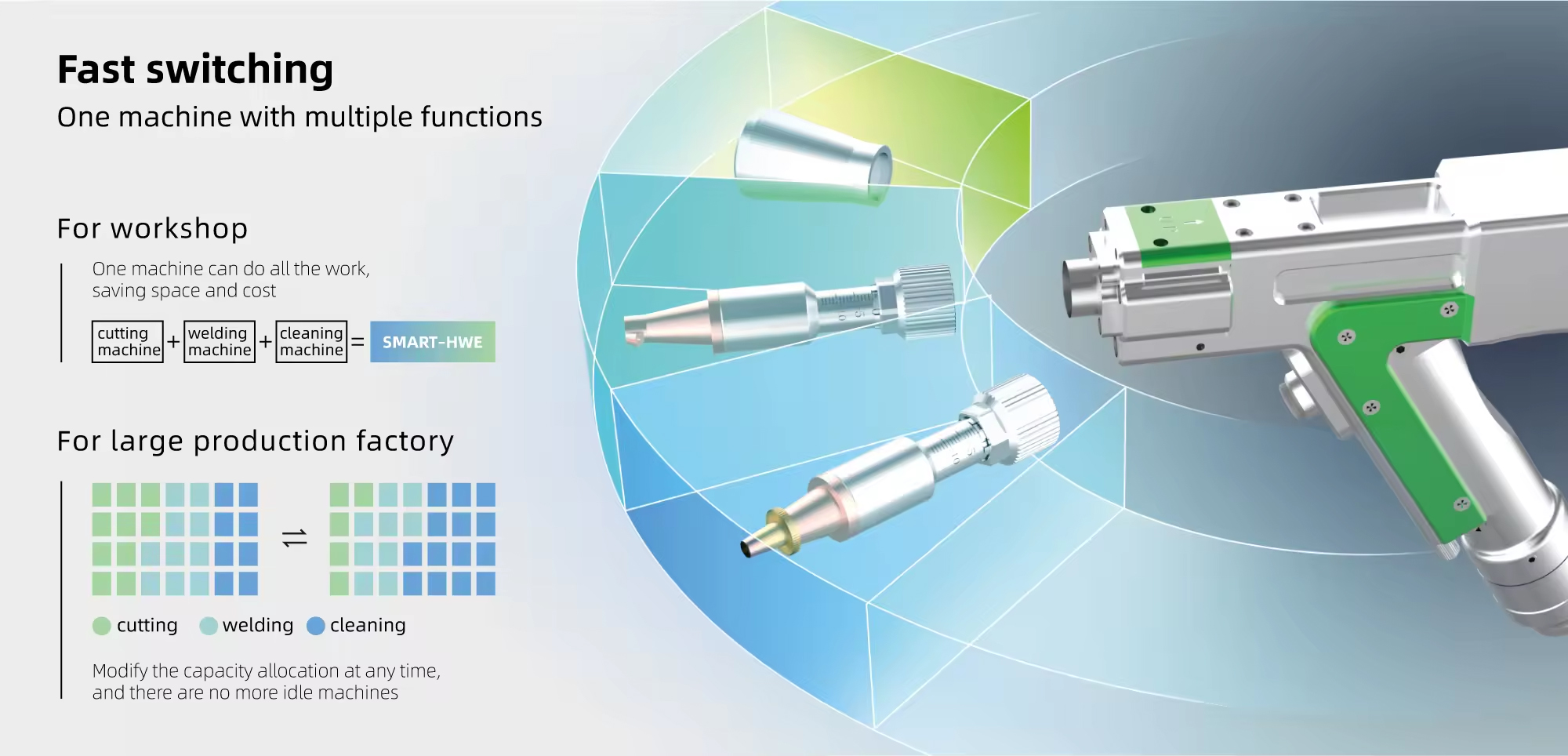

Combining cutting and welding in one machine significantly reduces production time and increases overall efficiency.

Versatility

This technology can handle a variety of materials, including metals, plastics, and composites, adapting to diverse industry needs.

Cost-Effectiveness

Although the initial investment may seem high, the long-term savings in labor, material waste, and maintenance make it a cost-effective solution.

Key Features of a Laser Cutting Welding Machine

1. Integrated Systems: Combines cutting and welding for seamless operations.

2. High-Power Lasers: Ensures deep penetration and fast processing speeds.

3. Automation Capabilities: Many machines are equipped with advanced automation features for enhanced productivity.

4. Minimal Heat-Affected Zone: Reduces material distortion and preserves the integrity of the workpiece.

5. User-Friendly Interfaces: Modern machines feature intuitive controls, making them accessible even for beginners.

Applications Across Industries

Aerospace

From turbine components to fuselage parts, these machines are indispensable in aerospace manufacturing, ensuring strength and precision.

Automotive

Laser cutting welding machines are widely used for chassis construction, exhaust systems, and intricate bodywork designs.

Electronics

Delicate components in electronics, such as circuit boards and connectors, benefit from the precision of laser technology.

Medical Devices

Surgical tools and implants require flawless manufacturing, which is achieved through laser cutting and welding.

Advantages Over Traditional Methods

Reduced Material Waste

Traditional cutting and welding often result in excessive material wastage. Laser technology minimizes this by ensuring precision and reducing errors.

Faster Turnaround Times

The integration of cutting and welding eliminates the need for multiple machines, speeding up production cycles.

Improved Aesthetics

Laser machines produce clean cuts and welds, enhancing the visual appeal of finished products.

Enhanced Safety

With automated systems, these machines reduce the need for manual intervention, minimizing workplace accidents.

Factors to Consider When Investing in a Laser Cutting Welding Machine

Material Compatibility

Ensure the machine can handle the materials you commonly work with.

Power Output

Higher power levels enable deeper penetration and faster processing speeds.

Automation Features

Look for machines with advanced automation for higher productivity.

Maintenance and Support

Choose a machine with reliable support and easy maintenance to minimize downtime.

Tips for Maximizing Efficiency

1. Regular Maintenance: Keep the machine clean and well-maintained to ensure consistent performance.

2. Proper Material Preparation: Ensure materials are free of contaminants before cutting or welding.

3. Optimized Settings: Adjust laser power, speed, and focus for each material type.

4. Skilled Operators: Train your team to handle the machine efficiently for better results.

The Future of Laser Cutting Welding Machines

AI-Driven Optimization

Artificial intelligence is enabling machines to self-adjust settings for optimal performance.

Sustainability

With reduced waste and energy-efficient operations, these machines are contributing to sustainable manufacturing practices.

Advanced Materials

As material science evolves, laser machines will adapt to process even more complex and durable materials.

Why the Laser Cutting Welding Machine Is a Must-Have

The laser cutting welding machine is not just a tool; it’s a gateway to innovation and efficiency. Its ability to deliver precision, speed, and versatility makes it an essential asset for businesses aiming to stay ahead in the competitive manufacturing landscape. Whether you’re in aerospace, automotive, electronics, or medical manufacturing, this technology is your partner in achieving excellence.