Laser Cleaning Wood: The Future of Precision Restoration

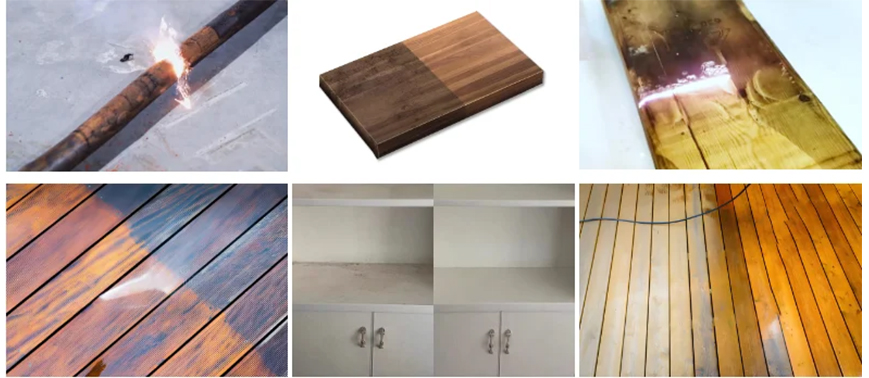

Wood restoration has always been a delicate process, demanding precision, care, and attention to detail. With laser cleaning wood technologies, the industry is witnessing a revolution that brings unmatched efficiency and accuracy. From preserving historical artifacts to rejuvenating modern wooden surfaces, laser cleaning is redefining how we approach wood care and restoration.

What Is Laser Cleaning for Wood?

Laser cleaning wood involves using focused laser beams to remove contaminants, such as dirt, paint, varnish, or other coatings, from wooden surfaces. Unlike traditional methods that rely on abrasive or chemical cleaning, laser technology ensures that the wood’s integrity remains intact.

How It Works

1. Laser Beam Targeting: The laser precisely targets the top layer of the wood.

2. Contaminant Removal: The energy vaporizes or dislodges contaminants without affecting the wood below.

3. Clean and Restored Surface: The process leaves the surface pristine and ready for further treatment.

Key Benefits of Laser Cleaning Wood

1. Non-Invasive and Safe

Laser cleaning wood is gentle on the material, ensuring the surface remains undamaged. This makes it ideal for delicate and antique wood restoration projects.

2. Precision and Accuracy

The technology allows for pinpoint cleaning, enabling restoration professionals to clean intricate designs, carvings, and details on wooden surfaces.

3. Eco-Friendly Process

By eliminating the need for harsh chemicals, laser cleaning is an environmentally friendly solution, producing minimal waste and no harmful residues.

4. Cost-Effective

Although the initial investment may be high, the long-term benefits, such as reduced labor costs and no recurring expenses for cleaning materials, make laser cleaning a cost-effective option.

5. Versatility

From furniture and flooring to artifacts and sculptures, laser cleaning wood can be applied across a wide range of restoration needs.

Applications of Laser Cleaning Wood

1. Historical Restoration

Preserving ancient wooden structures and artifacts requires a delicate touch. Laser cleaning offers a safe way to remove dirt and contaminants without damaging the original material.

2. Furniture Rejuvenation

Old and worn-out furniture can regain its former glory through laser cleaning, removing layers of paint or varnish effortlessly.

3. Flooring Maintenance

For wooden floors exposed to heavy foot traffic, laser cleaning can remove stubborn stains and restore their natural luster.

4. Artwork and Sculptures

Laser technology can clean intricate wooden sculptures and artwork without compromising their detailed craftsmanship.

Comparing Laser Cleaning to Traditional Methods

| Feature | Laser Cleaning Wood | Traditional Methods |

|---|---|---|

| Precision | High | Moderate |

| Material Impact | Minimal | Risk of Damage |

| Environmental Impact | Low | High |

| Cost Efficiency | Long-term Savings | Recurring Costs |

| Time Requirement | Fast | Slow |

Factors to Consider Before Using Laser Cleaning Wood

1. Type of Wood

Different wood types react differently to laser energy. Testing a small area ensures optimal results.

2. Level of Contamination

Heavily contaminated surfaces may require multiple cleaning passes or higher laser power settings.

3. Desired Outcome

Define whether the goal is complete removal of coatings or partial cleaning to retain some patina or finish.

4. Budget and Tools

Investing in a quality laser cleaning machine ensures effective and efficient cleaning.

Technological Advancements in Laser Cleaning Wood

1. Adjustable Laser Settings

Modern laser tools allow users to customize settings based on the wood type and cleaning requirements.

2. Compact Designs

Portable laser cleaning machines make on-site restoration projects more convenient.

3. AI Integration

Smart lasers with AI-driven controls ensure consistent results and prevent over-cleaning.

4. Energy Efficiency

Newer models consume less power, aligning with green energy initiatives.

Laser Cleaning Wood: A Step-by-Step Guide

1. Surface Assessment

Evaluate the type of wood and the contaminants to determine appropriate laser settings.

2. Calibration of Laser Settings

Adjust the power, frequency, and beam size for optimal cleaning results.

3. Cleaning Process

Move the laser beam steadily over the surface, ensuring even cleaning.

4. Post-Cleaning Inspection

Check the surface for uniform cleaning and repeat the process if necessary.

5. Protective Coating (Optional)

Apply a protective layer to preserve the cleaned wood from future damage.

Common Questions About Laser Cleaning Wood

Q1: Can laser cleaning damage wood?

No, when done correctly, laser cleaning is gentle and preserves the wood’s integrity.

Q2: Is laser cleaning suitable for all types of wood?

Yes, but the laser settings should be adjusted according to the wood type and condition.

Q3: How does laser cleaning compare in cost to traditional methods?

While the initial cost is higher, the long-term savings and efficiency outweigh traditional methods.

Q4: Does laser cleaning require special training?

Basic training is recommended to understand laser settings and safety protocols.

Conclusion

Laser cleaning wood is transforming the restoration and maintenance of wooden surfaces. Its precision, eco-friendliness, and versatility make it an ideal choice for preserving the timeless beauty of wood in historical artifacts, furniture, and flooring. As technology evolves, the accessibility and efficiency of laser cleaning will continue to grow, setting new standards in wood restoration.