Laser Cleaning Tools: Efficiency Redefined

In an era of technological marvels, laser cleaning tools stand out as a groundbreaking innovation. From removing rust and paint to preparing surfaces for industrial processes, these tools redefine precision and efficiency. But how do they work, and why are they becoming indispensable across industries? Let’s uncover the transformative potential of laser cleaning tools.

What Are Laser Cleaning Tools?

Laser cleaning tools are advanced devices that utilize laser technology to remove contaminants, coatings, or residues from surfaces. Unlike traditional methods, these tools offer a non-abrasive, eco-friendly, and highly precise cleaning solution.

Key Characteristics

1. Precision Cleaning: Targets contaminants without damaging the underlying material.

2. Eco-Friendly: Reduces chemical waste and promotes sustainability.

3. Versatility: Effective across various surfaces, including metals, plastics, and ceramics.

4. Cost-Effective: Minimizes long-term operational expenses.

How Do Laser Cleaning Tools Work?

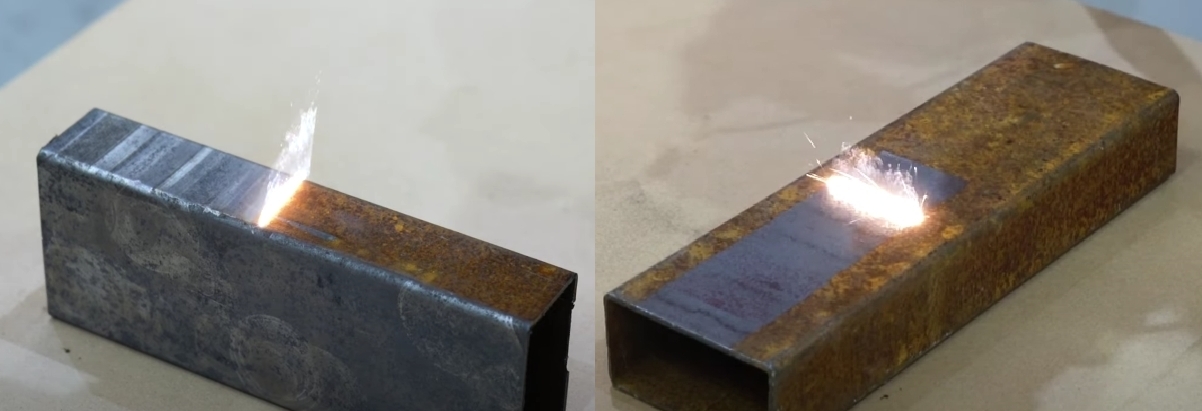

Laser cleaning operates through the principle of laser ablation. The laser beam interacts with the contaminant layer, vaporizing or dislodging it without harming the base material.

Process Overview

1. The laser beam is directed at the surface.

2. Energy from the laser heats the contaminant layer.

3. The contaminant is vaporized or loosened.

4. The clean surface is revealed.

This non-contact process ensures minimal wear and tear, making it ideal for delicate and intricate surfaces.

Benefits of Laser Cleaning Tools

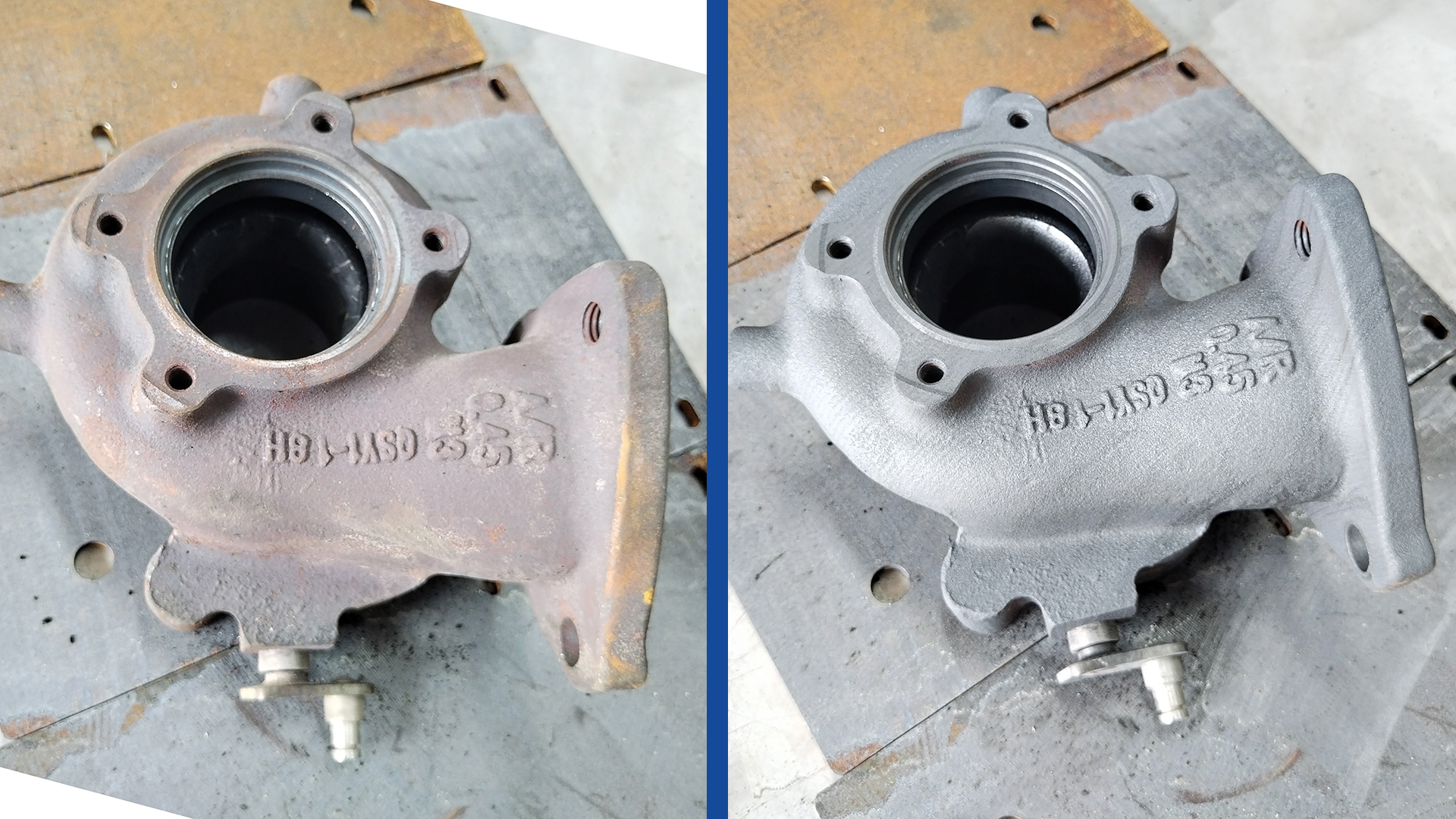

1. Non-Abrasive Cleaning

Traditional methods like sandblasting or chemical cleaning can damage surfaces. Laser cleaning tools, however, are gentle yet effective, preserving the integrity of the material.

2. Environmental Friendliness

By eliminating the need for harmful chemicals and reducing waste production, laser cleaning tools contribute to greener practices.

3. Time and Cost Efficiency

While the initial investment may be higher, the long-term savings on consumables, maintenance, and labor make laser tools cost-effective.

4. Enhanced Safety

With no chemicals or abrasives involved, these tools create a safer working environment for operators.

5. Precision and Control

Adjustable laser settings allow for precise cleaning, catering to both heavy-duty industrial needs and delicate restoration tasks.

Applications of Laser Cleaning Tools

1. Rust Removal

- Effectively eliminates rust from metal surfaces without causing damage.

2. Paint Stripping

- Removes old paint layers, preparing surfaces for repainting or coating.

3. Surface Preparation

- Prepares surfaces for welding, bonding, or coating.

4. Cultural Heritage Restoration

- Cleans delicate artifacts, sculptures, and paintings without damaging them.

5. Industrial Maintenance

- Ensures machinery and tools remain in optimal working condition.

Factors to Consider When Choosing Laser Cleaning Tools

1. Power Output

The power of the laser determines its cleaning capacity. Low-power tools are suitable for delicate tasks, while high-power tools are ideal for industrial applications.

2. Portability

For on-site cleaning, handheld or portable models offer convenience and flexibility.

3. Material Compatibility

Ensure the tool can handle the materials you need to clean, from metals to plastics and more.

4. Budget

While laser cleaning tools require an upfront investment, consider the long-term savings in maintenance and consumables.

5. Ease of Use

User-friendly interfaces and automation features enhance operational efficiency.

Comparing Laser Cleaning Tools to Traditional Methods

| Feature | Laser Cleaning Tools | Traditional Methods |

|---|---|---|

| Precision | High | Moderate to Low |

| Environmental Impact | Minimal | High |

| Maintenance | Low | High |

| Operational Speed | Fast | Slower |

| Cost Efficiency | Long-term Savings | High Recurring Costs |

Future Trends in Laser Cleaning Tools

1. AI Integration

Advanced tools with AI-driven settings for optimal cleaning performance.

2. Compact Designs

Portable and lightweight models for greater accessibility.

3. Cost Reductions

Technological advancements are expected to make laser cleaning tools more affordable.

4. Green Innovations

Further reduction in energy consumption and waste production.

FAQs About Laser Cleaning Tools

Q1: Are laser cleaning tools suitable for delicate surfaces?

Yes, adjustable settings ensure they can clean delicate surfaces without causing damage.

Q2: What is the lifespan of a laser cleaning tool?

With proper maintenance, these tools can last over a decade.

Q3: Are there ongoing costs associated with laser cleaning tools?

Minimal, as they require no consumables like chemicals or abrasives.

Q4: How do laser cleaning tools compare in cost to traditional methods?

While the initial cost is higher, long-term savings make them more economical.

Conclusion

Laser cleaning tools represent the future of efficient, eco-friendly, and precise surface cleaning. Their versatility and long-term benefits make them an invaluable asset across industries. Whether you’re in manufacturing, restoration, or maintenance, investing in laser cleaning tools ensures superior performance and sustainability.