Laser Cleaning Machine Cost: Everything You Need to Know

In a rapidly evolving world of technology, laser cleaning machines are revolutionizing the way we clean and restore surfaces. From industrial rust removal to delicate artwork restoration, these devices offer unparalleled precision, efficiency, and eco-friendliness. But what exactly influences the laser cleaning machine cost? Is it a worthwhile investment for your business? Let’s dive into the factors, benefits, and insights that matter.

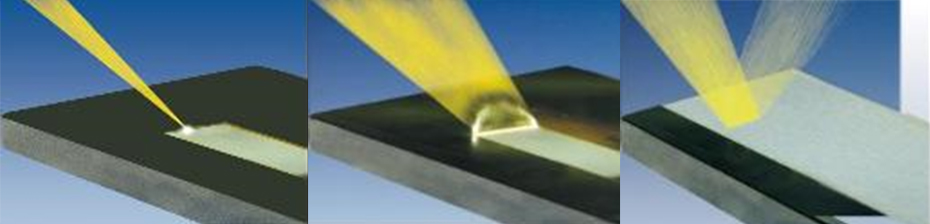

Understanding Laser Cleaning Machines

A laser cleaning machine is a modern solution that uses focused laser beams to remove contaminants, such as rust, paint, or dirt, from surfaces without causing damage. It’s a game-changer for industries requiring efficient and precise cleaning methods.

Key Features

1. Non-Abrasive Cleaning: Protects the underlying material while removing unwanted layers.

2. Eco-Friendly Operation: No need for harmful chemicals, reducing environmental impact.

3. Cost Efficiency: Long-term savings on consumables and maintenance.

4. Versatile Applications: Works on various materials, including metal, plastic, and glass.

How Much Does a Laser Cleaning Machine Cost?

The cost of a laser cleaning machine can vary widely based on several factors, with prices ranging from $10,000 to over $100,000. Understanding these factors will help you make an informed decision.

Factors Affecting the Cost

1. Power Output

- Machines with higher wattage, such as 1000W or more, are designed for heavy-duty tasks and typically cost more.

2. Technology and Features

- Advanced features like automation, AI integration, and customizable settings can increase the price.

3. Portability

- Handheld and portable models are often more affordable compared to large, stationary systems.

4. Material Compatibility

- Machines designed to clean a broader range of materials might come at a premium.

5. Warranty and Support

- Comprehensive warranties and customer support can add to the cost but provide peace of mind.

Why Invest in a Laser Cleaning Machine?

1. Efficiency and Precision

Laser cleaning is faster and more precise than traditional methods, reducing labor costs and operational downtime.

2. Long-Term Savings

While the initial investment might seem high, the machine’s durability and low maintenance costs result in significant savings over time.

3. Versatile Applications

These machines are ideal for various industries, including aerospace, automotive, and manufacturing.

4. Environmental Benefits

Laser cleaning eliminates the need for toxic chemicals, promoting sustainable practices and reducing hazardous waste.

5. Competitive Edge

Incorporating laser cleaning technology can give businesses a competitive advantage by improving efficiency and reducing costs.

Comparing Laser Cleaning Costs to Traditional Methods

Chemical Cleaning

• Cost: Lower upfront cost but recurring expenses for chemicals.

• Drawback: Hazardous to the environment and workers.

Abrasive Blasting

• Cost: Moderate, depending on the equipment.

• Drawback: Risk of surface damage and high waste production.

Laser Cleaning

• Cost: Higher initial investment but lower operating costs.

• Benefit: Safe, efficient, and eco-friendly.

Applications of Laser Cleaning Machines

1. Rust and Paint Removal

° Perfect for cleaning industrial equipment, vehicles, and infrastructure.

2. Surface Preparation

° Prepares surfaces for welding, painting, or coating.

3. Delicate Cleaning

° Suitable for restoring historical artifacts, artworks, and sensitive machinery.

4. Maintenance

° Keeps machinery and tools in optimal condition with minimal effort.

5. Industrial Use

° Widely used in automotive, aerospace, and manufacturing sectors for cleaning and restoration.

Choosing the Right Laser Cleaning Machine

1. Assess Your Needs

Evaluate the scale and type of cleaning required to determine the right power output and features.

2. Set a Budget

Consider not only the initial cost but also long-term savings and return on investment.

3. Research Features

Look for features like portability, user-friendly interfaces, and safety mechanisms.

4. Compare Options

Evaluate different models and manufacturers to find the best balance of cost and performance.

5. Check Support and Training

Ensure the supplier provides adequate training and after-sales support.

FAQs About Laser Cleaning Machine Costs

Q1: Is a high-cost laser cleaning machine worth it?

Yes, especially for businesses requiring precision and efficiency in their cleaning processes.

Q2: Are there ongoing costs associated with laser cleaning machines?

Minimal, as they require less maintenance and no consumables like chemicals.

Q3: How long does a laser cleaning machine last?

With proper maintenance, these machines can last over a decade.

Q4: Can laser cleaning machines handle delicate surfaces?

Yes, with adjustable settings, they can clean delicate materials without causing damage.

Future Trends in Laser Cleaning Technology

1. AI Integration

° Smarter machines with automated adjustments for optimal performance.

2. Affordable Models

° As technology advances, costs are expected to decrease, making them more accessible.

3. Compact Designs

° Lightweight and portable options for greater flexibility.

4. Green Initiatives

° Increased focus on eco-friendly and sustainable practices.

Conclusion

Investing in a laser cleaning machine is a strategic move for industries prioritizing efficiency, precision, and sustainability. While the upfront cost may be substantial, the long-term benefits far outweigh the investment. By understanding the factors influencing costs, businesses can make informed decisions and stay ahead in their respective fields.