Revolutionizing Cleaning: Insights Into Laser Cleaning Machine 1000W Price

In a world where precision, efficiency, and eco-friendliness are non-negotiable, the laser cleaning machine 1000W stands as a game-changer. Whether you’re dealing with industrial rust removal, delicate artifact cleaning, or preparing surfaces for advanced applications, this powerful tool delivers unmatched results. This article delves deep into its pricing, functionality, and why it’s a worthy investment for your operations.

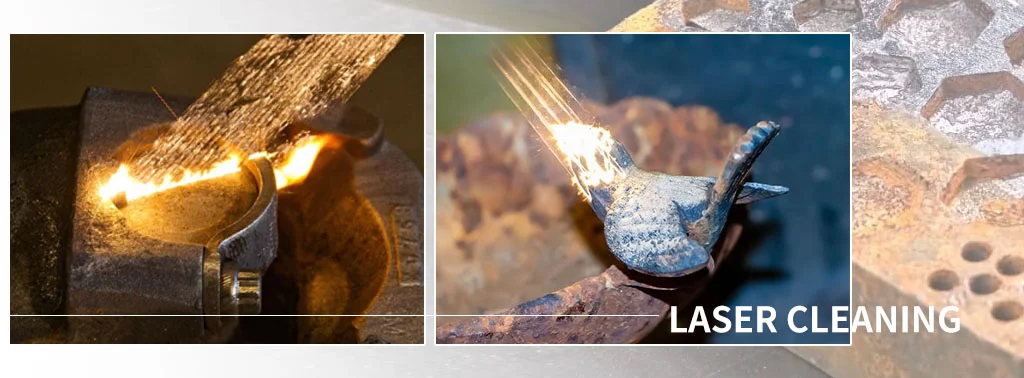

Understanding Laser Cleaning Machines

A laser cleaning machine utilizes high-powered laser technology to remove contaminants from surfaces without damaging the underlying material. The 1000W model, in particular, is designed for heavy-duty industrial applications, offering a perfect balance between power and precision.

Key Features

1. High Power Output: Capable of handling large-scale and demanding cleaning tasks.

2. Non-Abrasive: Ensures surfaces remain undamaged during cleaning.

3. Eco-Friendly: Operates without harmful chemicals, making it a sustainable option.

4. Minimal Maintenance: Long-lasting design reduces upkeep requirements.

5. Versatility: Compatible with various materials, from metals to plastics.

How Much Does a Laser Cleaning Machine 1000W Cost?

The price of a laser cleaning machine 1000W depends on several factors, including the manufacturer, additional features, and after-sales services. On average, prices range from $25,000 to $80,000, making it a significant investment for industries prioritizing efficiency and sustainability.

Factors Influencing Price

1. Power Efficiency: Higher energy efficiency models may come at a premium but offer long-term savings.

2. Automation Capabilities: Machines with automated systems and AI integration often cost more.

3. Material Compatibility: Versatile machines capable of handling diverse materials may have higher upfront costs.

4. Warranty and Support: Comprehensive after-sales support and extended warranties can add to the price.

Benefits of Investing in a 1000W Laser Cleaning Machine

1. High Efficiency

A 1000W laser cleaning machine handles tough industrial contaminants quickly, reducing downtime and boosting productivity.

2. Cost Savings

Though the upfront cost is high, long-term savings come from reduced labor, consumables, and maintenance costs.

3. Environmental Impact

Laser cleaning eliminates the need for harsh chemicals, reducing hazardous waste and environmental damage.

4. Versatility

This machine adapts to diverse industries, including aerospace, automotive, restoration, and manufacturing.

5. Durability

Designed for longevity, these machines ensure reliable performance for years.

Applications of a 1000W Laser Cleaning Machine

1. Rust Removal

Effectively eliminates rust from industrial machinery, vehicles, and infrastructure.

2. Paint Stripping

Strips paint and coatings without damaging the underlying surface, ensuring smooth reapplication.

3. Surface Preparation

Prepares surfaces for welding, painting, or coating by removing contaminants.

4. Precision Cleaning

Ideal for delicate tasks such as cleaning molds, tools, and historical artifacts.

5. Maintenance

Maintains operational efficiency by cleaning equipment and machinery.

Choosing the Right 1000W Laser Cleaning Machine

1. Evaluate Your Needs

Understand your cleaning requirements, including the materials, scale of cleaning, and desired results.

2. Power Output

A 1000W model is powerful enough for industrial needs but ensure it aligns with your specific applications.

3. Additional Features

Look for features like automation, user-friendly interfaces, and advanced cooling systems.

4. Support and Training

Choose a manufacturer that provides training and robust after-sales support.

5. Budget

Ensure the machine fits your budget while offering value for money in terms of performance and longevity.

Comparing Laser Cleaning Machines to Traditional Methods

Chemical Cleaning

• Advantages: Effective for specific contaminants.

• Disadvantages: Hazardous and environmentally damaging.

Abrasive Cleaning

• Advantages: Suitable for certain large-scale applications.

• Disadvantages: Risk of surface damage and high waste generation.

Laser Cleaning

• Advantages: Precise, efficient, and eco-friendly.

• Disadvantages: Higher upfront cost but superior in long-term efficiency.

FAQs About Laser Cleaning Machine 1000W

Q1: What industries benefit from a 1000W laser cleaning machine?

Industries like aerospace, automotive, restoration, and manufacturing extensively use these machines.

Q2: How long does a 1000W laser cleaning machine last?

With proper maintenance, these machines can last over 50,000 operational hours.

Q3: Are laser cleaning machines eco-friendly?

Yes, they operate without harmful chemicals, producing minimal waste.

Q4: Is a 1000W model suitable for delicate surfaces?

Yes, with proper settings, it can clean delicate surfaces without causing damage.

Future Trends in Laser Cleaning Technology

The field of laser cleaning continues to evolve, with innovations making machines more accessible and efficient. Key trends include:

1. AI Integration: Advanced automation and adaptive cleaning systems.

2. Cost Reductions: As technology matures, prices are expected to become more affordable.

3. Portability: Compact and lightweight designs for greater flexibility.

The Value of a 1000W Laser Cleaning Machine

Investing in a laser cleaning machine 1000W is more than a purchase; it’s a commitment to precision, efficiency, and sustainability. By embracing this cutting-edge technology, industries can reduce costs, improve operational efficiency, and minimize environmental impact. Whether you need rust removal, surface preparation, or delicate cleaning, the 1000W laser cleaning machine delivers results that exceed expectations.