Laser Cleaning for Sale: Revolutionizing Surface Cleaning Solutions

Imagine a world where cleaning industrial surfaces is precise, efficient, and environmentally friendly. Laser cleaning for sale offers this revolutionary approach, catering to industries that demand high precision and cost-effective solutions. Whether you need to remove rust, paint, or other contaminants, laser cleaning technology stands as the ultimate game-changer in modern cleaning systems.

What is Laser Cleaning?

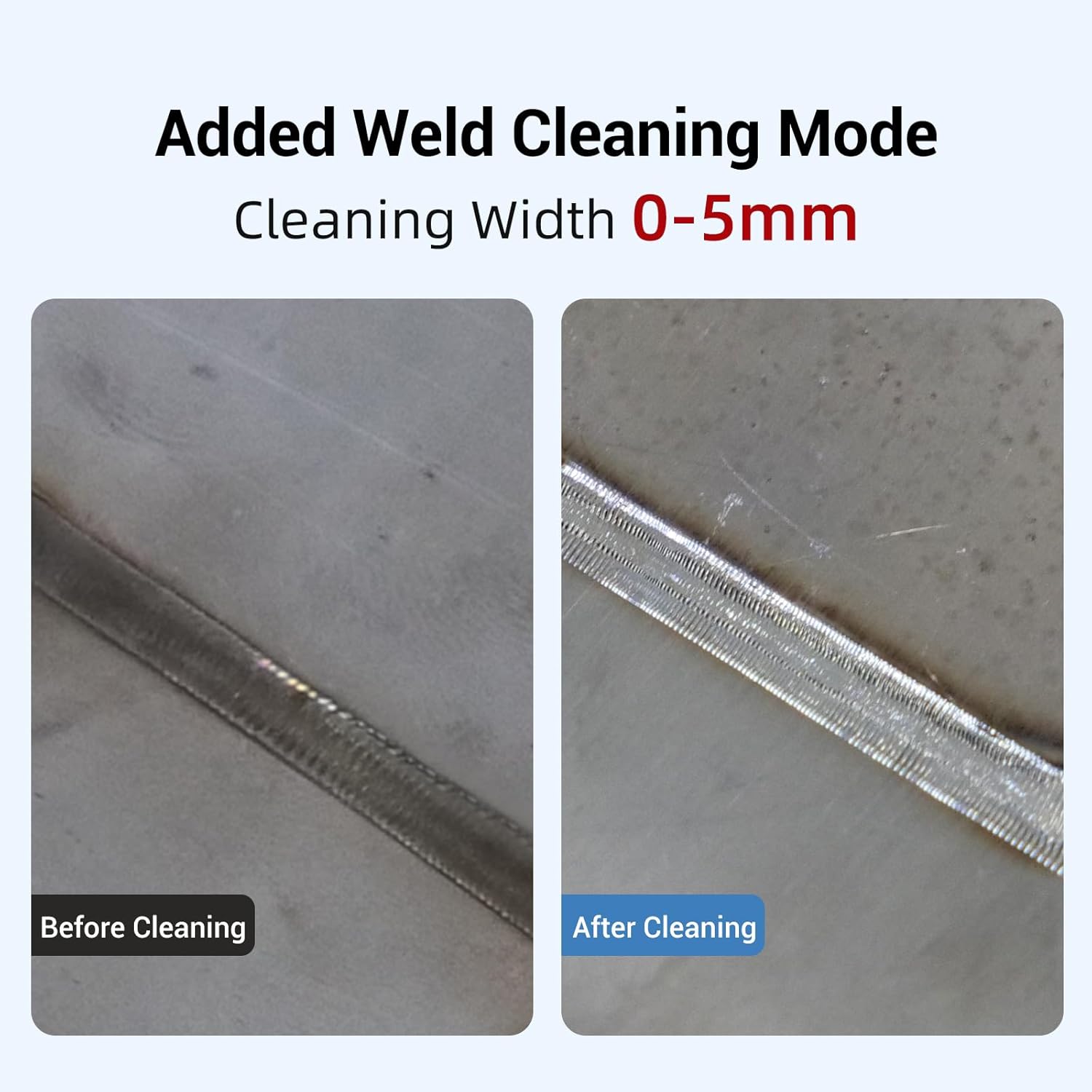

Laser cleaning is an advanced process that uses concentrated laser beams to remove unwanted materials from surfaces. It’s a non-abrasive, eco-friendly, and highly efficient method suited for various industries.

How Does Laser Cleaning Work?

The Science Behind the Process

Laser cleaning operates on the principle of laser ablation. When a laser beam targets a surface, it heats and vaporizes contaminants without damaging the underlying material.

Steps in Laser Cleaning

1. Laser Emission: A highly focused laser beam is directed at the surface.

2. Contaminant Removal: The laser’s heat energy dislodges and vaporizes contaminants.

3. Surface Protection: The base material remains intact, ensuring no structural damage.

This precise mechanism makes laser cleaning the preferred choice for industries seeking efficient and non-invasive cleaning methods.

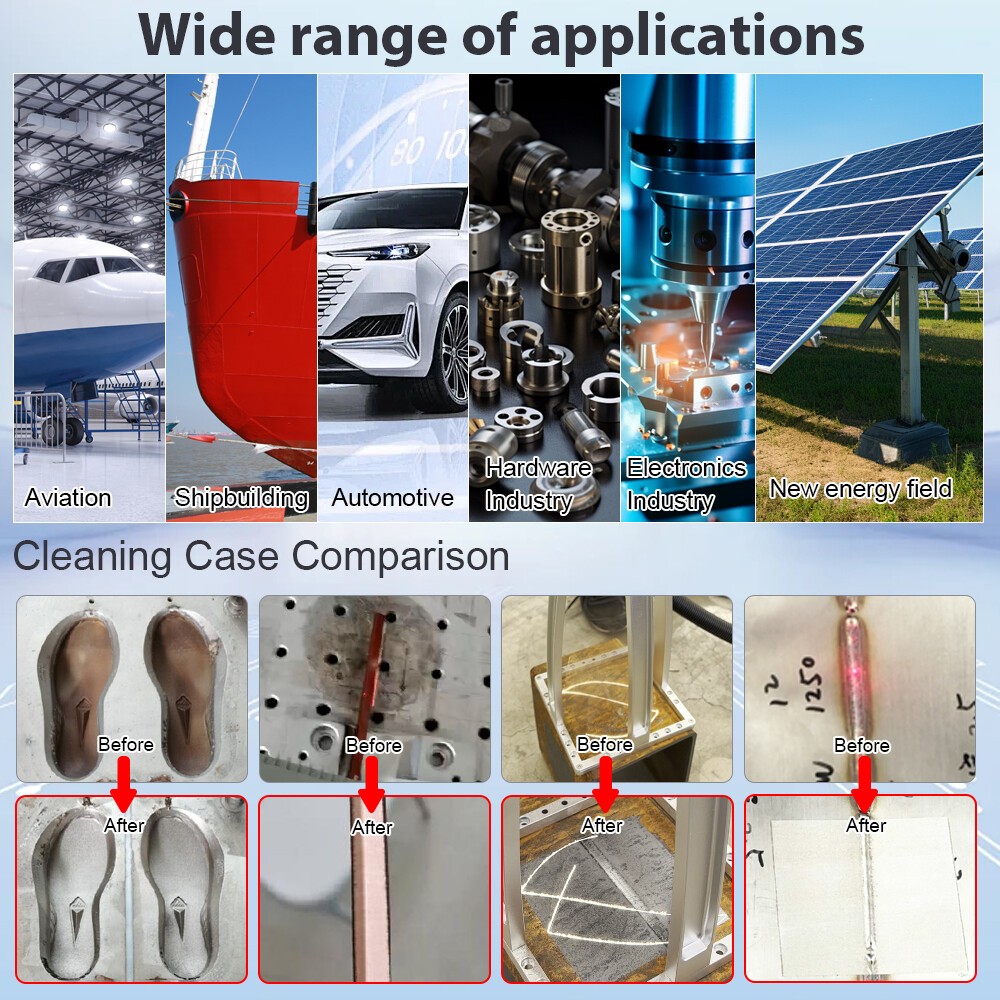

Applications of Laser Cleaning Technology

1. Industrial Applications

• Rust Removal: Ideal for cleaning rusted machinery and metal surfaces.

• Paint Stripping: Effective in removing old coatings for reapplication.

2. Automotive Industry

• Component Maintenance: Cleans engine parts and other metal components efficiently.

• Surface Preparation: Prepares surfaces for welding or painting.

3. Aerospace and Defense

• High-Precision Cleaning: Removes contaminants from sensitive components.

• Aircraft Maintenance: Cleans turbine blades and other critical parts.

4. Restoration and Conservation

• Art Restoration: Removes dirt and corrosion from sculptures and metal artworks.

• Historical Conservation: Cleans artifacts and monuments without causing damage.

Why Choose Laser Cleaning for Sale?

1. Environmentally Friendly

Unlike chemical-based cleaning methods, laser cleaning doesn’t produce hazardous waste.

2. High Precision

Laser cleaning ensures minimal impact on the base material, making it ideal for delicate surfaces.

3. Cost-Effective

While the initial investment may seem significant, the long-term savings in consumables and maintenance make it a worthy choice.

4. Versatility

Suitable for cleaning various materials, including metal, plastic, and stone.

5. Efficiency

Laser cleaning systems work faster than traditional methods, reducing downtime and increasing productivity.

Understanding Laser Cleaning Machine Prices

When exploring laser cleaning for sale, understanding the pricing structure is crucial. Prices vary based on factors such as power, portability, and application.

| Power Level | Estimated Price (USD) | Applications |

|---|---|---|

| 50W - 100W | $10,000 - $20,000 | Small-scale cleaning, precision tasks |

| 200W - 500W | $25,000 - $60,000 | Medium industrial applications |

| 1000W+ | $60,000+ | Heavy-duty industrial cleaning |

Factors to Consider When Buying Laser Cleaning Machines

1. Power Requirements

Choose a power level based on your specific cleaning needs. Higher power levels are better for heavy-duty tasks, while lower levels are ideal for precision work.

2. Portability

Portable machines are suitable for on-site applications, while stationary models are ideal for factory setups.

3. Budget

Understand your budget and compare prices to ensure you get the best value for your investment.

4. Application Scope

Identify the types of surfaces and contaminants you plan to clean to select the right machine.

The Future of Laser Cleaning Technology

The laser cleaning industry is poised for significant advancements:

1. Integration with AI

Future machines will feature AI-powered controls for automated cleaning and improved precision.

2. Enhanced Portability

Design innovations will make portable laser cleaning machines more compact without compromising performance.

3. Affordable Solutions

As technology evolves, the cost of laser cleaning machines is expected to decrease, making them accessible to a broader audience.

Tips for Maximizing Your Laser Cleaning Investment

1. Regular Maintenance: Ensure your machine operates at peak performance with proper upkeep.

2. Operator Training: Train your staff to use the equipment safely and efficiently.

3. Application-Specific Settings: Customize the machine’s settings based on the material and cleaning requirements.

Laser cleaning for sale represents the pinnacle of modern surface cleaning technology. With its precision, efficiency, and environmental benefits, it’s an investment that pays off in the long run. Explore the possibilities and transform the way you approach industrial cleaning tasks today.