Understanding Laser Cleaning Cost Per Hour: Factors, Pricing & Industry Insights

Introduction: The Economics of Laser Cleaning

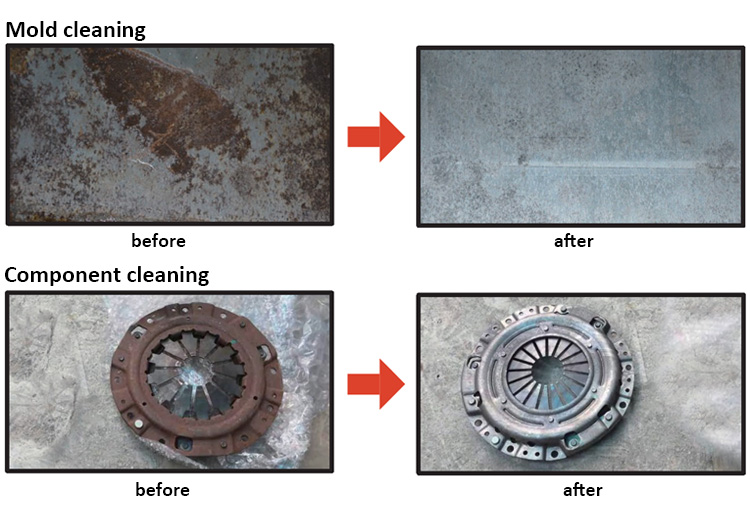

Laser cleaning is revolutionizing surface treatment across various industries, from automotive and aerospace to marine and heavy manufacturing. It provides a non-contact, chemical-free, and highly precise cleaning method, eliminating contaminants such as rust, paint, and grease without damaging the underlying material.

However, one of the most common questions businesses ask is: How much does laser cleaning cost per hour? The answer depends on multiple factors, including laser power, material type, labor, and operational costs. This article will break down the key pricing components and help you determine whether laser cleaning is a cost-effective solution for your needs.

1. How Much Does Laser Cleaning Cost Per Hour?

The cost of laser cleaning per hour varies based on multiple factors, but on average, pricing ranges from $50 to $500 per hour.

General Cost Breakdown by Industry

| Industry | Estimated Cost Per Hour | Application |

|---|---|---|

| Automotive | $100 – $300 | Rust, grease, and paint removal |

| Aerospace | $200 – $500 | Aircraft parts restoration |

| Manufacturing | $150 – $400 | Equipment maintenance, mold cleaning |

| Marine | $250 – $500 | Ship hull and offshore platform cleaning |

| Electronics | $100 – $250 | Precision component cleaning |

These prices depend on wattage, labor, and project complexity. Lower-power lasers (100W-500W) are cheaper per hour, whereas higher-power industrial lasers (1000W-2000W) command premium rates.

2. Factors Influencing Laser Cleaning Cost Per Hour

1. Laser Power and Equipment Costs

• Low-power lasers (100W-500W):Suitable for light rust removal, graffiti cleaning, and small-scale jobs.

• Mid-range lasers (500W-1000W):Used for industrial applications like factory equipment cleaning.

• High-power lasers (1000W-2000W+):Designed for heavy-duty applications like ship restoration and large-scale decontamination.

More powerful lasers clean faster but have higher operating costs, leading to higher per-hour rates.

2. Labor and Technician Expertise

• Basic operators:$50 – $100 per hour

• Certified laser specialists:$100 – $250 per hour

Laser cleaning often requires trained professionals, particularly in industries like aerospace and precision manufacturing.

3. Surface Type and Contamination Level

• Light contaminants (dust, minor oxidation)→ Lower cost per hour

• Heavy corrosion, thick paint layers→ Higher cost per hour due to increased time and power usage

4. Operational & Maintenance Expenses

Unlike chemical stripping or sandblasting, laser cleaning has lower consumable costs, but electricity, maintenance, and cooling systems add to the overall hourly rate.

5. Geographic Location and Market Demand

• Urban & industrial areas→ Higher rates due to demand

• Remote locations→ Travel and setup fees increase costs

3. Pricing Models for Laser Cleaning Services

1. Hourly Pricing Model

• Best for:Small jobs, spot cleaning, precision work

• Average cost:$100 – $500 per hour

2. Project-Based Pricing

• Best for:Large industrial contracts, ship hull cleaning, factory maintenance

• Pricing:$5,000 – $50,000 per project

3. Subscription & Contract Pricing

• Best for:Businesses needing regular equipment maintenance

• Pricing:$3,000 – $10,000 per month

Subscription models help companies reduce per-hour rates by offering long-term contracts.

4. Comparing Laser Cleaning Costs with Other Methods

| Cleaning Method | Cost Per Hour | Pros | Cons |

|---|---|---|---|

| Laser Cleaning | $100 - $500 | Eco-friendly, precise, minimal waste | High initial equipment cost |

| Sandblasting | $50 - $150 | Effective for large areas | Abrasive, high cleanup cost |

| Chemical Stripping | $30 - $100 | Cheap for mass applications | Hazardous, waste disposal required |

| Dry Ice Blasting | $150 - $400 | Non-abrasive, effective | Requires compressed air, expensive consumables |

Laser cleaning reduces long-term costs by eliminating chemical purchases, abrasive media, and extensive labor.

5. How to Reduce Laser Cleaning Costs Per Hour

1. Optimize Power Settings

Using the correct wattage for each material ensures efficient cleaning without wasting energy.

2. Choose the Right Laser for the Job

Avoid overpaying for high-power lasers when a mid-range system can achieve the same results.

3. Utilize Automation

For large projects, robotic laser systems can reduce manual labor costs and increase efficiency.

4. Contract Bulk Services

Many businesses negotiate lower rates by signing annual maintenance contracts with laser cleaning providers.

6. Is Laser Cleaning Worth the Investment?

Key Benefits of Laser Cleaning Over Traditional Methods:

• Lower long-term costs(No consumables, reduced labor)

• Non-damaging to materials(Ideal for precision industries)

• Environmentally friendly(No hazardous chemicals, reduced waste)

• High efficiency(Faster cleaning times, higher productivity)

For industries requiring frequent maintenance, laser cleaning saves money over time despite the higher hourly rate.

Final Thoughts: Choosing the Right Laser Cleaning Solution

Understanding laser cleaning cost per hour helps businesses make informed decisions when choosing a cost-effective cleaning method. Whether you’re hiring a service or investing in equipment, evaluating laser power, job complexity, and labor costs ensures you get the best value for your investment.