Industrial Laser Cleaning Machine: The Future of Surface Treatment

Introduction: Why Industrial Laser Cleaning Machines Are Revolutionizing Surface Treatment

Imagine a world where rust, paint, and contaminants disappear instantly—without chemicals, abrasives, or damage to the underlying material. Traditional cleaning methods, like sandblasting, chemical stripping, and grinding, are messy, inefficient, and environmentally harmful.

Enter the industrial laser cleaning machine—a high-precision, eco-friendly, and cost-efficient technology designed to handle the most demanding cleaning tasks. From automotive manufacturing to aerospace maintenance, shipbuilding to historical restoration, industries worldwide are embracing laser cleaning for its unmatched speed, efficiency, and sustainability.

This guide explores how industrial laser cleaning works, its benefits, applications, and cost considerations, helping businesses make informed decisions about adopting this cutting-edge technology.

1. What Is an Industrial Laser Cleaning Machine?

An industrial laser cleaning machine is a high-intensity fiber laser system used to remove rust, paint, coatings, grease, and contaminants from metal and other surfaces. Unlike traditional methods, laser cleaning is:

• Non-contact– Eliminates mechanical wear and surface damage.

• Eco-friendly– Produces no waste, reducing environmental impact.

• Cost-effective– Lowers operational costs by eliminating consumables.

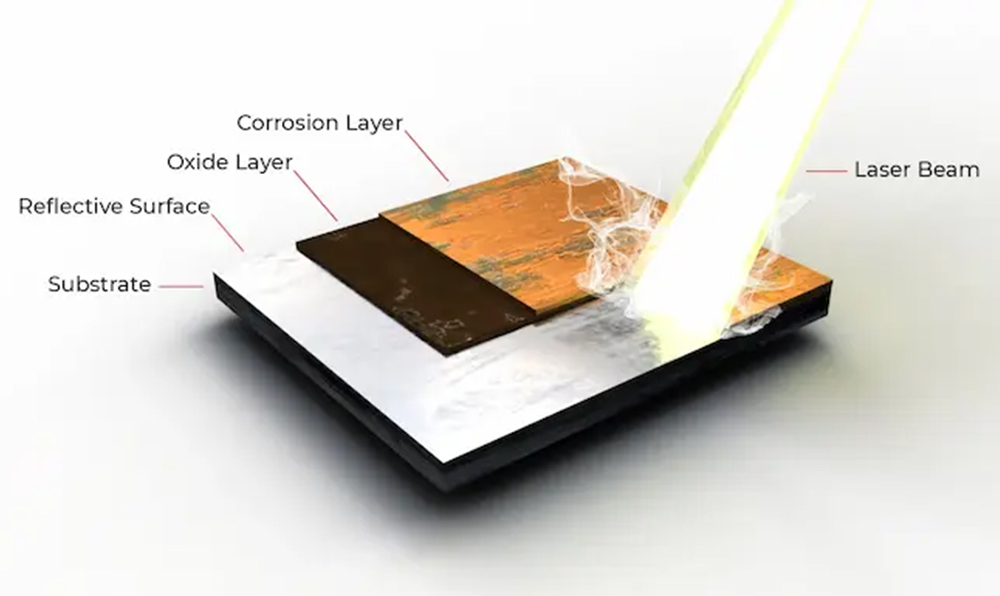

How Does Laser Cleaning Work?

1. The laser beam is directed at the contaminated surface.

2. The rust, paint, or dirt absorbs the laser energy, vaporizing instantly.

3. The base material remains intact, with no abrasions or chemical residues.

4. The process is fast, safe, and repeatablewith minimal setup.

With adjustable laser power levels, industrial cleaning machines can be fine-tuned for delicate applications or high-speed heavy-duty cleaning.

2. Advantages of an Industrial Laser Cleaning Machine

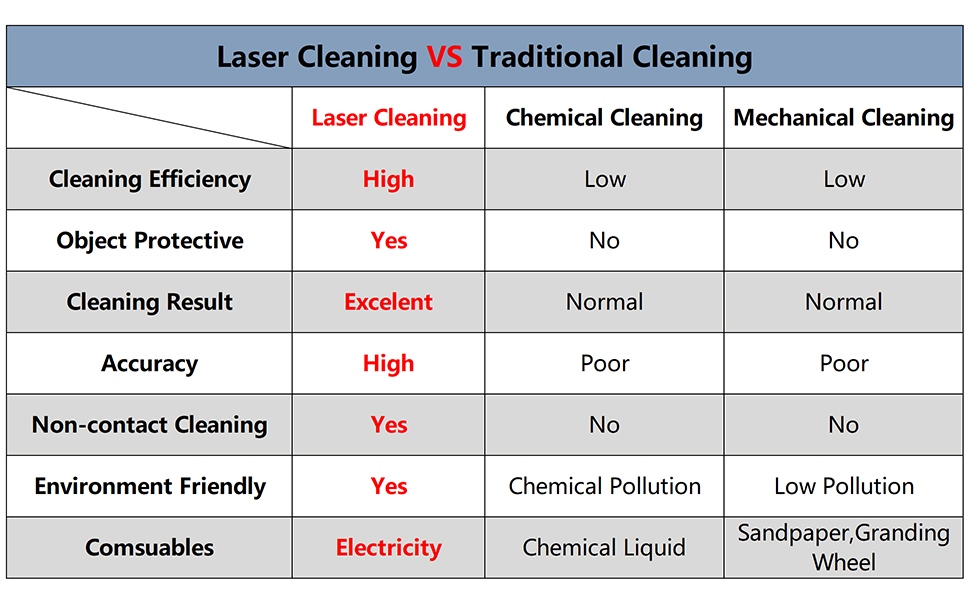

Laser cleaning has rapidly gained popularity as a superior alternative to traditional surface treatment methods. Here’s why:

1. No Damage to Base Material

• Traditional methods(grinding, sandblasting) remove material along with contaminants, leading to wear.

• Laser cleaning selectively removes unwanted layers, preserving the integrity of metal surfaces.

2. Chemical-Free and Environmentally Friendly

• No hazardous solvents or chemicals, reducing pollution and disposal costs.

• Meets strict environmental regulationsfor industries prioritizing sustainability.

3. Reduced Operational Costs

• No need for abrasives, chemicals, or extensive labor.

• Lower maintenance costswith minimal equipment wear.

4. High Precision & Automation

• Programmable laser systemsensure consistent, repeatable cleaning.

• Automated setupsintegrate with robotic arms for large-scale industrial applications.

5. Versatile Applications

• Cleans metals, composites, concrete, stone, and even delicate artifacts.

• Used across automotive, aerospace, marine, energy, and infrastructure industries.

These advantages make industrial laser cleaning machines an essential tool for modern manufacturing and maintenance.

3. Key Applications of Industrial Laser Cleaning Machines

Industrial laser cleaning technology is used across multiple sectors, offering efficiency in rust removal, paint stripping, and surface preparation.

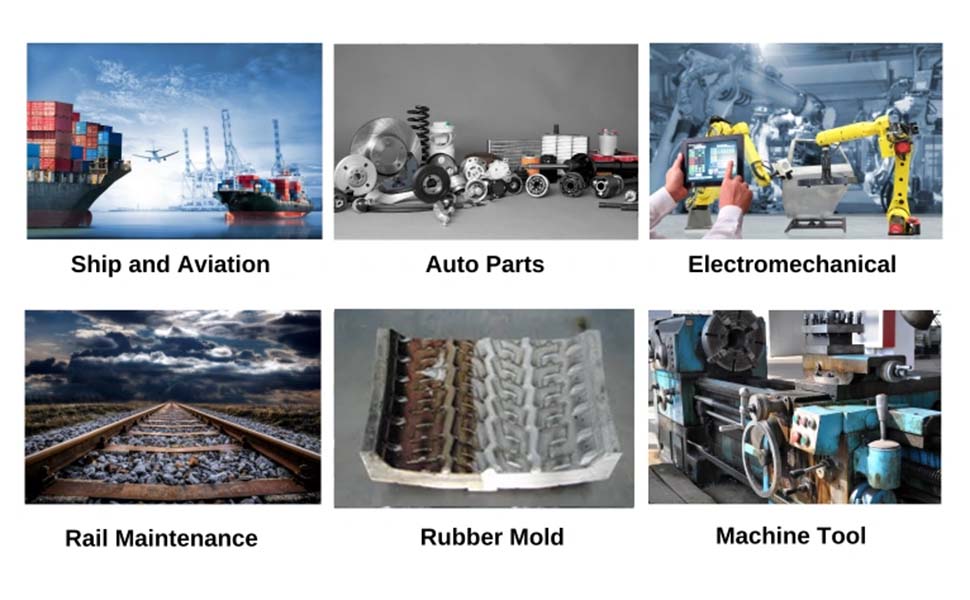

1. Automotive & Aerospace Industries

• Removes oxidation, coatings, and contaminantsfrom metal parts.

• Prepares aircraft components and car framesfor welding and painting.

2. Manufacturing & Heavy Equipment Maintenance

• Cleans machinery, molds, and toolsto extend lifespan.

• Removes welding residues and metal oxidation.

3. Shipbuilding & Marine Maintenance

• Strips corrosion and marine growthfrom ship hulls.

• Prepares surfaces for anti-corrosion coatings.

4. Oil, Gas & Energy Sector

• Cleans pipelines, turbines, and industrial tanks.

• Restores offshore equipment and power plantswithout chemical exposure.

5. Infrastructure & Historical Preservation

• Removes graffiti and pollution stainsfrom buildings and monuments.

• Restores delicate stone, wood, and metal artifactswithout abrasion.

Laser cleaning’s non-destructive nature and precision make it ideal for industries requiring highly controlled surface treatment.

4. How Much Does an Industrial Laser Cleaning Machine Cost?

The cost of an industrial laser cleaner depends on power output, automation level, and additional features.

Typical Price Ranges

| Laser Power | Price Range (USD) | Best For |

|---|---|---|

| 100W – 500W | $10,000 – $30,000 | Small-scale cleaning, manual operations |

| 1000W – 2000W | $30,000 – $80,000 | Medium industrial cleaning, automotive, metalworking |

| 3000W+ | $80,000+ | High-volume manufacturing, heavy industry |

Factors Affecting Pricing

• Power Output– Higher wattage increases speed and cleaning depth.

• Cooling System– Water-cooled systems cost more but support continuous operation.

• Automation & Robotics– CNC integration and AI-assisted targeting increase price but enhance efficiency.

While initial costs are high, the long-term savings on consumables, labor, and maintenance make laser cleaning a cost-effective investment.

5. Choosing the Right Industrial Laser Cleaning Machine

Selecting the best laser cleaning machine depends on:

1. Power Requirements

• Low-power models (100W–500W)for light cleaning tasks.

• Medium-power (1000W–2000W)for industrial maintenance.

• High-power (3000W+)for heavy-duty applications.

2. Cooling System

• Air-cooled systemsfor short operational cycles.

• Water-cooled modelsfor continuous, industrial cleaning.

3. Automation & Integration

• Handheld modelsfor flexibility and mobility.

• CNC-controlled systemsfor mass production.

Matching the right specifications ensures efficiency, cost savings, and long-term reliability.

6. Future of Industrial Laser Cleaning Technology

As industries shift toward automation, sustainability, and cost-efficiency, laser cleaning is becoming the standard for:

• Zero-waste, eco-friendly manufacturing.

• AI-driven automation and robotic integration.

• High-speed, large-scale cleaning operations.

Advancements in laser technology, AI control, and energy efficiency will further drive the adoption of industrial laser cleaning machines across all major industries.

Final Thoughts: Industrial Laser Cleaning Machines Are the Future of Surface Treatment

With unmatched precision, cost-effectiveness, and environmental benefits, industrial laser cleaning machines are transforming maintenance and manufacturing worldwide.

For businesses looking to reduce operational costs, improve efficiency, and meet sustainability goals, adopting laser cleaning technology is a strategic move toward the future of industrial surface treatment.