Transforming Industrial Cleaning: The Power of the Industrial Laser Cleaner

Industrial cleaning has evolved. Gone are the days of abrasive scrubbing, harmful chemicals, and inefficient results. The industrial laser cleaner offers a groundbreaking solution, merging cutting-edge technology with practical applications across countless industries. This article explores its features, benefits, and impact on modern cleaning standards.

What is an Industrial Laser Cleaner?

An industrial laser cleaner is an advanced tool designed to remove contaminants like rust, paint, grease, and dirt from surfaces using laser ablation technology. It is widely used in manufacturing, maintenance, and restoration industries due to its efficiency, precision, and eco-friendly operation.

Key Features

1. Precision Cleaning: Targets specific areas without damaging the base material.

2. Eco-Friendly: Eliminates the need for chemicals or consumables.

3. High Efficiency: Provides fast and thorough cleaning for large surfaces.

4. Low Maintenance: Requires minimal upkeep compared to traditional tools.

5. Versatility: Works on a wide range of materials, including metals, plastics, and ceramics.

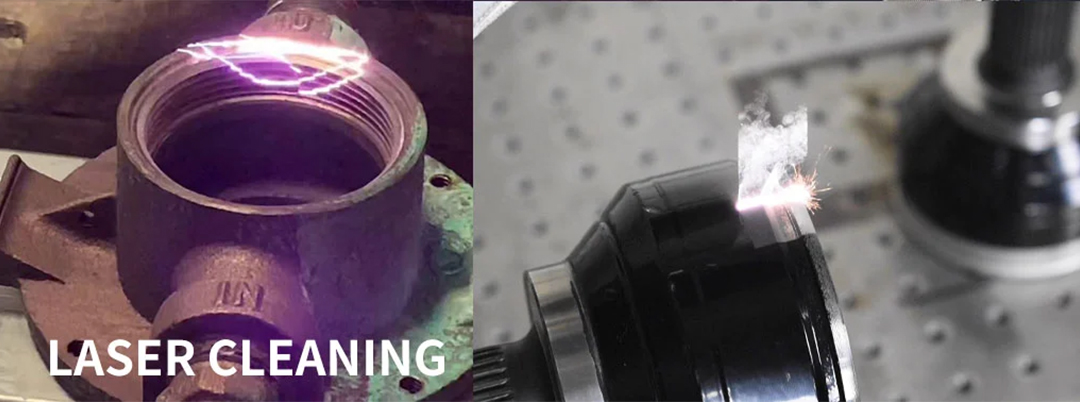

How Does an Industrial Laser Cleaner Work?

The device uses focused laser beams to interact with contaminants on a surface. This interaction causes the contaminants to vaporize or break into particles, leaving the underlying material clean and intact.

The Process

1. Laser Ablation: High-intensity energy removes contaminants by breaking their molecular bonds.

2. Non-Contact Cleaning: Ensures no physical contact with the surface, preventing scratches or damage.

3. Selective Cleaning: Targets specific contaminants without affecting surrounding areas.

Applications of Industrial Laser Cleaners

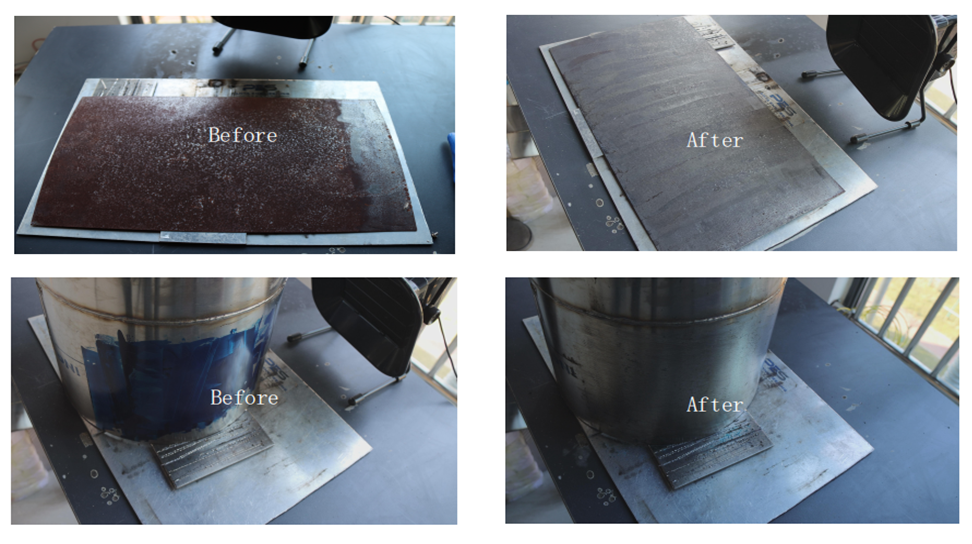

1. Rust and Corrosion Removal

Effectively eliminates rust and corrosion from machinery, vehicles, and structural components, extending their lifespan.

2. Paint and Coating Removal

Cleanly strips paint and coatings without harming the underlying material, making it ideal for automotive and aerospace applications.

3. Surface Preparation

Prepares surfaces for welding, bonding, or coating by ensuring a contaminant-free area.

4. Heritage and Artifact Restoration

Preserves historical artifacts and sculptures by removing dirt and decay delicately.

5. Industrial Maintenance

Maintains machinery and equipment by removing grease, oil, and other residues.

Advantages of Industrial Laser Cleaners

1. High Precision

Industrial laser cleaners can target specific contaminants without affecting nearby areas, making them ideal for delicate or high-value surfaces.

2. Environmentally Friendly

Laser cleaning eliminates the need for harmful chemicals or abrasive materials, reducing waste and environmental impact.

3. Cost-Effective

Although the initial investment is higher, the long-term savings from reduced labor, consumables, and maintenance costs are substantial.

4. Versatility

From automotive to aerospace, these cleaners are compatible with a wide range of industries and applications.

5. Safety and Cleanliness

The process generates minimal waste and poses no health risks when proper safety measures are followed.

Factors to Consider When Choosing an Industrial Laser Cleaner

1. Power Output

Higher wattage models clean faster and are better suited for heavy-duty tasks, while lower wattage models are ideal for precision work.

2. Material Compatibility

Ensure the device supports the materials you frequently work with, such as metals, plastics, or ceramics.

3. Portability

Depending on your operational needs, consider a portable model for on-site cleaning.

4. Ease of Use

Opt for user-friendly interfaces and intuitive controls to maximize productivity.

5. After-Sales Support

Choose a manufacturer that provides robust warranties, training, and maintenance services.

Comparing Industrial Laser Cleaners to Traditional Methods

Chemical Cleaning

• Advantages: Effective for certain contaminants.

• Disadvantages: Involves hazardous chemicals and waste disposal issues.

Abrasive Cleaning

• Advantages: Suitable for large-scale tasks.

• Disadvantages: Can damage surfaces and generate significant waste.

Industrial Laser Cleaning

• Advantages: Precise, efficient, and environmentally friendly.

• Disadvantages: Higher upfront cost but offers better ROI.

Cost of Industrial Laser Cleaners

Industrial laser cleaners range from $30,000 to $100,000, depending on features, power, and manufacturer.

Factors Influencing Cost

1. Power and Performance: Higher wattage models cost more but clean faster and more efficiently.

2. Additional Features: Automation, advanced cooling systems, and customizations add to the price.

3. Maintenance: Long-term maintenance costs are minimal compared to traditional methods.

Additional Costs

• Training: Proper training ensures safe and efficient operation.

• Spare Parts: Availability of replacement parts affects long-term usability.

FAQs About Industrial Laser Cleaners

Q1: Are industrial laser cleaners safe to use?

Yes, they are safe when used with proper training and safety equipment, such as protective eyewear.

Q2: Can they clean all materials?

While effective on most metals, plastics, and ceramics, testing is recommended for unique or sensitive surfaces.

Q3: What industries benefit from laser cleaning?

Industries like automotive, aerospace, electronics, and restoration see significant advantages.

Q4: How long do these machines last?

With proper maintenance, industrial laser cleaners can last over 50,000 operational hours.

Future Trends in Industrial Laser Cleaning Technology

As technology advances, industrial laser cleaners are becoming more efficient and accessible. Key trends include:

1. AI Integration: Smarter systems for automated and adaptive cleaning.

2. Compact Designs: Enhancing portability and usability.

3. Cost Reductions: Driving broader adoption across industries.

Why Choose an Industrial Laser Cleaner?

Industrial laser cleaners represent the pinnacle of cleaning technology. They offer unmatched precision, efficiency, and eco-friendliness, transforming how industries handle cleaning and surface preparation. Whether you’re maintaining machinery, restoring artifacts, or preparing surfaces for welding, this innovative tool provides superior results with minimal environmental impact.