How Strong Is Laser Welding? A Comprehensive Guide

Laser welding is a revolutionary process known for its exceptional strength and precision. From aerospace to jewelry, the technique has proven its ability to create robust and reliable joints across various industries. If you’re curious about how strong laser welding truly is and why it surpasses traditional welding methods, this detailed guide offers all the answers.

Understanding the Mechanics Behind Laser Welding

The Basics of Laser Welding

Laser welding utilizes a concentrated beam of light to melt materials at their interface, creating a seamless and durable bond. The energy density of the laser beam allows for deep penetration, ensuring strength and precision even with minimal heat input.

The Science of Strength

The strength of a laser weld is influenced by several factors, including material properties, weld geometry, and laser parameters. With proper setup, the joints can exhibit strength equal to or greater than the base material itself.

Factors Contributing to the Strength of Laser Welding

Material Compatibility

Laser welding works well with a wide range of materials, including steel, aluminum, titanium, and even plastics. The compatibility ensures that the welds maintain their integrity under stress.

Precision Heat Input

Unlike traditional welding methods, laser welding provides precise heat application, minimizing thermal distortion and preserving the mechanical properties of the material.

Depth of Penetration

Laser welding achieves significant penetration depths, making it ideal for creating strong, load-bearing joints in thick materials.

Weld Geometry

Optimized weld designs, such as keyhole or conduction welds, ensure consistent strength across the joint, reducing the risk of failure under dynamic loads.

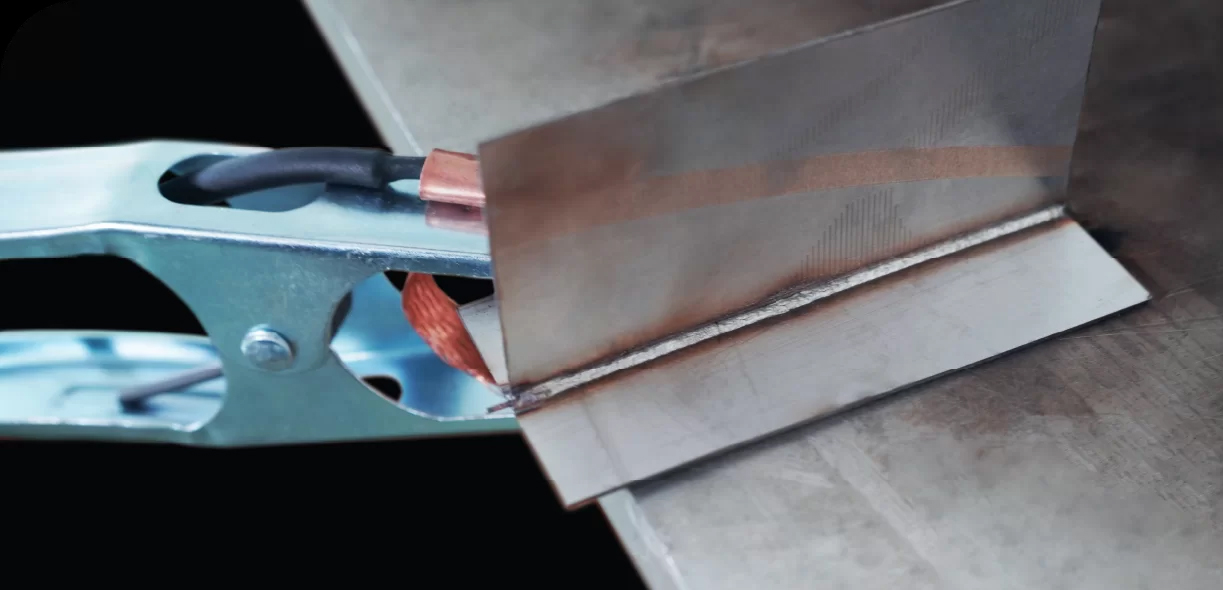

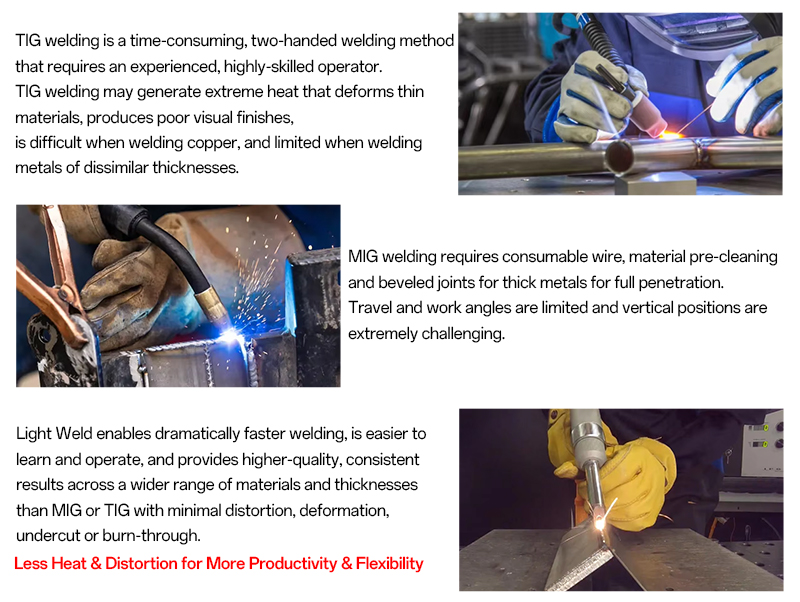

Comparing Laser Welding to Traditional Methods

Strength Under Stress

Laser welds are often stronger than those created through traditional methods like TIG or MIG welding due to reduced impurities and precise control over the weld pool.

Minimal Thermal Effects

The localized heat of a laser weld prevents the surrounding material from softening or deforming, which is a common issue with traditional welding methods.

Durability and Fatigue Resistance

Laser welds exhibit superior fatigue resistance, ensuring long-term reliability even under cyclic loads.

Real-World Applications Highlighting Laser Welding's Strength

Aerospace Engineering

In aerospace, where safety and reliability are paramount, laser welding is used to create high-strength joints in turbine blades, fuselages, and fuel tanks.

Automotive Manufacturing

Laser welding ensures the structural integrity of vehicle chassis, providing lightweight yet durable solutions.

Medical Devices

Implants and surgical tools demand precision and strength, both of which are achieved through laser welding techniques.

Consumer Electronics

Laser welding’s precision and reliability make it ideal for sealing and joining delicate electronic components.

Common Questions About Laser Welding Strength

Can Laser Welds Replace Traditional Welds in All Applications?

While laser welds are exceptionally strong, their application depends on factors like material type, joint design, and cost considerations.

How Does Joint Preparation Affect Strength?

Proper surface preparation is critical. Contaminants can weaken the weld by introducing impurities into the joint.

Are Laser Welds Suitable for High-Stress Environments?

Yes, laser welds excel in high-stress environments due to their consistent quality and resistance to fatigue.

Enhancing Laser Weld Strength: Best Practices

Material Preparation

Ensure clean and smooth surfaces to prevent defects and improve weld quality.

Optimized Parameters

Adjust laser power, speed, and focus to achieve the desired depth and strength.

Post-Weld Treatments

Processes like heat treatment or surface polishing can further enhance the durability of laser welds.

Regular Maintenance

Keep the laser welding equipment in optimal condition to maintain consistent performance.

The Future of Laser Welding: Strength Redefined

Advancements in Laser Technology

The development of high-power fiber lasers is enabling even stronger and more precise welds, opening up possibilities for new applications.

AI Integration

Artificial intelligence is optimizing weld parameters in real-time, ensuring consistent quality and strength across production lines.

Sustainable Welding Solutions

As industries shift towards greener practices, laser welding’s efficiency and reduced waste make it a preferred choice.

Final Insights

Laser welding is a game-changer in modern manufacturing, delivering unparalleled strength, precision, and efficiency. Understanding how strong laser welding can be is key to leveraging its full potential across various applications. By adopting best practices and staying updated on technological advancements, industries can continue to benefit from the unmatched reliability of this cutting-edge technique.