Your Complete Guide to Handheld Laser Welders for Sale

A handheld laser welder for sale offers unmatched precision, versatility, and efficiency in welding applications. Whether you’re in the automotive, aerospace, or manufacturing industry, this compact yet powerful tool is transforming the way professionals achieve clean, strong, and reliable welds. If you’re looking for detailed insights into what makes these machines invaluable, this comprehensive guide is your answer.

Why Consider a Handheld Laser Welder?

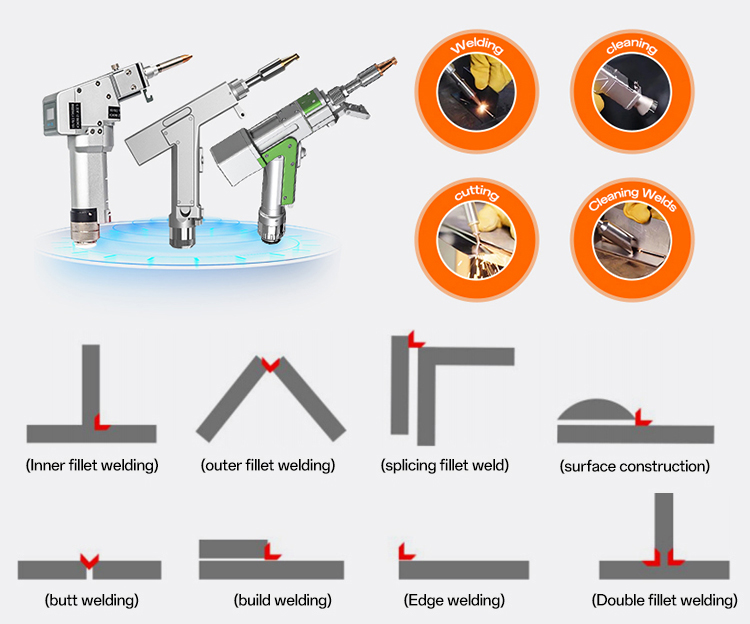

Precision Meets Portability

Handheld laser welders provide pinpoint accuracy while remaining lightweight and portable. This combination allows operators to achieve seamless welds in hard-to-reach areas without compromising quality.

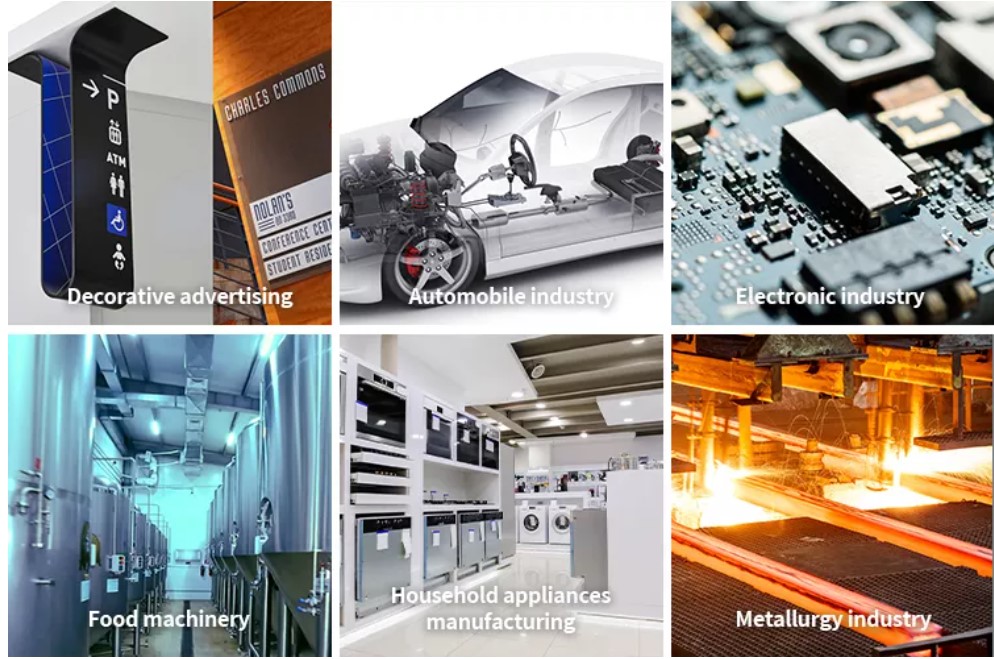

Versatile Applications

These machines work effortlessly on a variety of materials, including stainless steel, aluminum, and copper. Their adaptability extends to diverse industries, making them a universal solution for welding needs.

Time and Cost Efficiency

Faster welding speeds and minimal material waste significantly reduce production time and costs, offering businesses a substantial return on investment.

Key Features of Handheld Laser Welders

Compact Design

The lightweight build ensures ease of use, allowing operators to work for extended periods without fatigue.

Adjustable Laser Settings

Customizable power outputs and focus settings enable precise welds on materials of varying thickness.

Real-Time Monitoring

Advanced models include real-time monitoring systems to ensure optimal performance and safety.

Low Maintenance Requirements

Durable components and minimal consumables reduce the need for frequent maintenance, saving both time and money.

Industries Benefiting from Handheld Laser Welders

Automotive Sector

Handheld laser welders are ideal for repairing lightweight automotive parts, ensuring durability and aesthetic appeal.

Aerospace Industry

These machines meet the stringent standards required for aerospace applications, providing strong and precise welds in critical components.

Jewelry Crafting

The accuracy of handheld laser welders makes them perfect for intricate jewelry designs, repairs, and resizing tasks.

Electronics Manufacturing

From circuit boards to delicate components, these welders deliver clean, consistent results without damaging sensitive materials.

How to Choose the Right Handheld Laser Welder

Evaluate Your Requirements

Consider the types of materials and thicknesses you’ll be working with to determine the necessary laser power and features.

Prioritize Portability

Ensure the welder is lightweight and ergonomically designed for extended use in various environments.

Look for Safety Features

Essential features include protective shields, emergency shut-off systems, and laser beam guards.

Read Reviews

Customer testimonials and expert reviews can provide valuable insights into the reliability and performance of specific models.

Factors Influencing the Price of Handheld Laser Welders

Power Output

High-powered models capable of welding thicker materials typically come at a premium.

Advanced Features

Additional functionalities, such as touchscreens and automation, can increase the overall cost.

Material Compatibility

Machines designed to handle a wide range of materials are often more expensive due to their versatility.

Warranty and Support

Investing in a model with a comprehensive warranty and customer support ensures long-term reliability and peace of mind.

Benefits of Investing in a Handheld Laser Welder

Enhanced Productivity

The speed and accuracy of laser welding significantly improve workflow efficiency.

Environmentally Friendly

Reduced material waste and lower energy consumption make handheld laser welders an eco-conscious choice.

Long-Term Savings

While the initial investment may be higher, the reduced maintenance costs and operational efficiency result in substantial long-term savings.

Maintenance Tips for Longevity

Regular Lens Cleaning

Remove dust and debris to maintain laser precision and prevent performance issues.

Monitor Cooling Systems

Ensure the cooling mechanism is functioning correctly to prevent overheating during prolonged use.

Inspect Electrical Components

Periodically check connections to avoid disruptions in laser performance.

Follow Manufacturer Guidelines

Adhere to recommended maintenance schedules for optimal machine performance.

Emerging Trends in Laser Welding

Automation Integration

AI-driven systems are making laser welding more efficient and accessible, reducing the need for skilled operators.

Sustainable Manufacturing

Advancements in eco-friendly laser technologies are driving sustainable practices across industries.

Enhanced User Interfaces

Modern handheld laser welders now feature intuitive controls and real-time feedback systems, simplifying operation for new users.

Where to Find Handheld Laser Welders for Sale

Online Retailers

Numerous platforms offer a wide selection of handheld laser welders. Compare prices, features, and reviews to make an informed decision.

Specialized Distributors

Authorized distributors often provide expert advice and after-sales support, ensuring a seamless purchasing experience.

Trade Shows and Expos

Industry events are excellent opportunities to explore the latest models and innovations in laser welding technology.

Unlock the Potential of Handheld Laser Welders

Investing in a handheld laser welder for sale is a strategic decision for professionals seeking efficiency, precision, and versatility. By understanding their features, benefits, and applications, you can harness this cutting-edge technology to elevate your projects and stay ahead in a competitive market. Whether you’re upgrading your workshop or expanding your capabilities, these machines are your gateway to unparalleled success.