The Revolutionary Power of Hand Held Laser Welder Machines

A hand held laser welder machine is not just a tool; it’s a game-changer for industries seeking efficiency, precision, and versatility. Imagine achieving impeccable welds on diverse materials with unmatched ease and speed. From small-scale workshops to expansive manufacturing units, these machines redefine what’s possible in welding technology. Let’s explore their benefits, mechanics, and transformative potential.

What Makes a Hand Held Laser Welder Machine Stand Out?

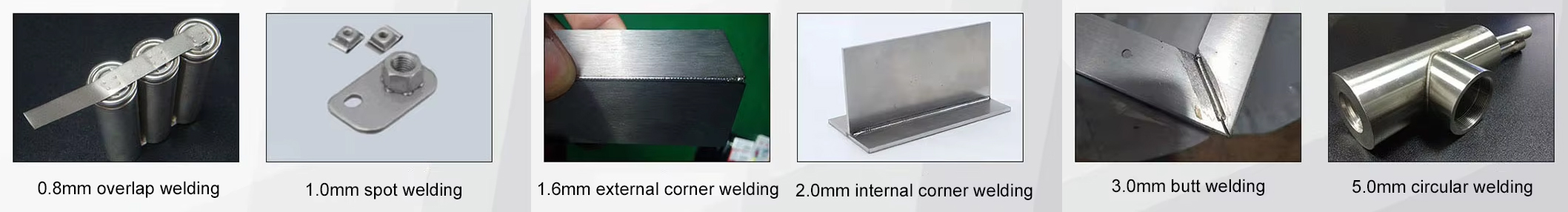

Unparalleled Versatility

Hand held laser welder machines are compatible with a variety of materials, including stainless steel, aluminum, carbon steel, and even complex alloys. This adaptability makes them invaluable across industries.

Efficiency Meets Precision

Laser welding is faster and more precise than traditional welding methods. The focused laser beam minimizes heat-affected zones, ensuring cleaner and stronger welds.

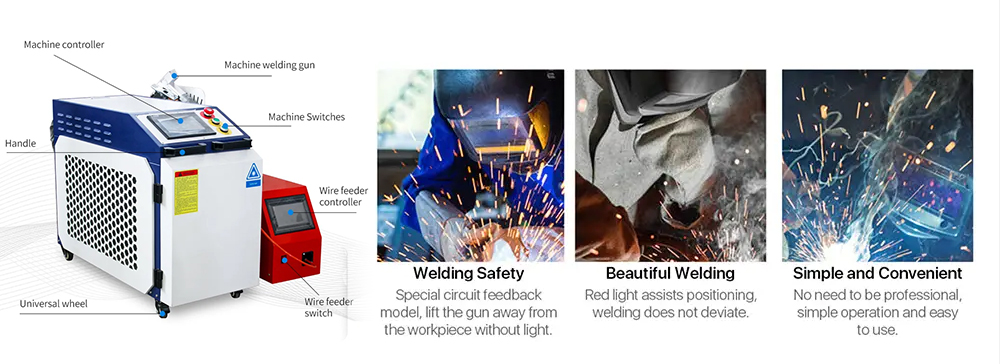

Portable Convenience

Unlike bulky welding equipment, these machines are compact and portable, allowing users to operate in tight spaces or remote locations without compromising performance.

How Hand Held Laser Welder Machines Work

Laser Beam Generation

The device generates a high-energy laser beam that is directed onto the welding surface.

Material Fusion

The intense heat from the laser melts the material, creating a seamless joint as it cools.

Real-Time Adjustments

Advanced models often include features for adjusting parameters like laser intensity and beam focus, enabling customized welds for different applications.

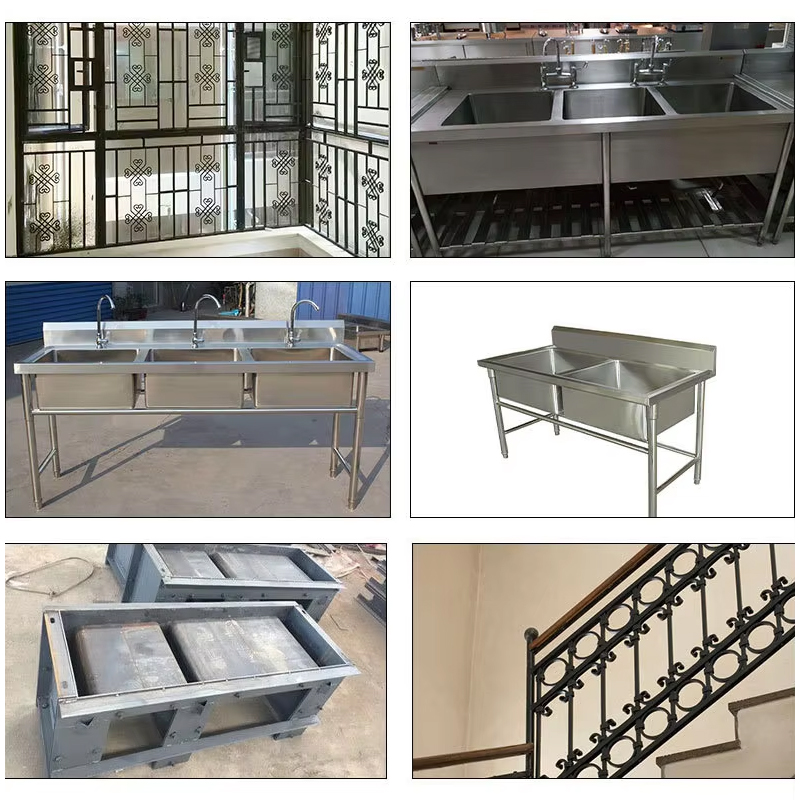

Applications Across Industries

Automotive Manufacturing

Hand held laser welders are perfect for repairing and fabricating lightweight components, enhancing fuel efficiency and performance.

Aerospace Engineering

The precision of these machines ensures reliable joints in critical components, where failure is not an option.

Jewelry Making

Laser welders allow for intricate repairs and designs, ensuring minimal material wastage and flawless aesthetics.

Medical Devices

These machines create hygienic, durable welds for surgical tools and implants, meeting stringent industry standards.

Benefits That Justify the Investment

Reduced Operating Costs

Laser welding consumes less power compared to traditional methods, reducing operational expenses over time.

Minimal Maintenance

The robust design of hand held laser welders ensures durability and requires minimal upkeep, further lowering costs.

Enhanced Productivity

With faster welding speeds and reduced prep time, these machines increase productivity, making them ideal for high-demand environments.

Eco-Friendly Operation

Laser welding produces fewer emissions and reduces material wastage, contributing to sustainable manufacturing practices.

Factors Influencing the Cost of Hand Held Laser Welder Machines

Power Output

Higher wattage machines can handle thicker materials but come with a higher price tag.

Features and Add-Ons

Advanced features like touchscreens, automation capabilities, and safety enhancements can increase the cost.

Material Compatibility

Machines designed to weld a wide range of materials often cost more due to their enhanced functionality.

Brand and Warranty

Opting for a reliable brand with a comprehensive warranty may involve a higher initial investment but ensures long-term savings.

Tips for Choosing the Right Hand Held Laser Welder Machine

Evaluate Your Needs

Consider the materials and thicknesses you’ll be working with to select an appropriate power range.

Look for Portability

Ensure the machine is lightweight and easy to maneuver, especially if you’ll be working in various locations.

Check for Safety Features

Features like laser shielding and emergency shutoff are essential for operator safety.

Read Reviews and Testimonials

Learn from other users’ experiences to gauge the machine’s performance and reliability.

Emerging Trends in Laser Welding Technology

Automation Integration

AI-powered laser welding systems are becoming increasingly popular, offering consistent results with minimal human intervention.

Green Welding Solutions

Sustainability is driving the development of eco-friendly laser welding technologies, reducing the carbon footprint of manufacturing processes.

Enhanced User Interfaces

Modern machines feature intuitive touchscreens and real-time monitoring capabilities, making them accessible even for novice operators.

Maintenance Tips for Longevity

Clean the Lens Regularly

Dust and debris can affect laser precision.

Inspect the Cooling System

Ensure the cooling system functions correctly to prevent overheating.

Check Electrical Connections

Loose connections can lead to inconsistent performance.

Follow Manufacturer Guidelines

Adhering to maintenance schedules provided by the manufacturer will extend the machine’s lifespan.

The Future of Hand Held Laser Welder Machines

As industries continue to evolve, the demand for efficient, portable, and precise welding solutions will only grow. Hand held laser welders are not just tools; they are catalysts for innovation, paving the way for advanced manufacturing practices. By understanding their capabilities and applications, you can leverage this technology to meet the demands of a dynamic market.