Unlocking the Potential of the Hand Held Laser Cleaner

Precision. Efficiency. Eco-friendliness. These are the hallmarks of the hand held laser cleaner—a revolutionary tool transforming how industries approach cleaning and surface preparation. Whether you’re tackling stubborn rust, removing paint, or preparing surfaces for further processing, this device sets new standards in innovation.

What is a Hand Held Laser Cleaner?

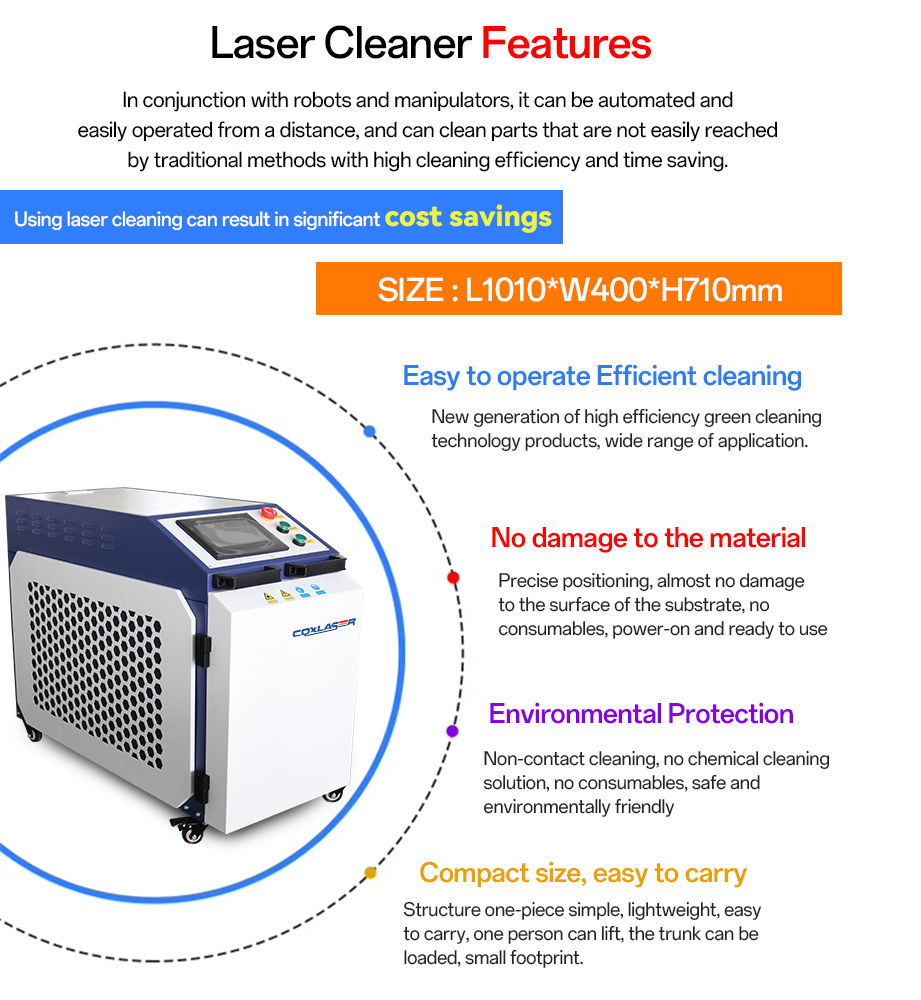

A hand held laser cleaner is a portable, high-precision device that uses laser technology to clean surfaces by removing contaminants such as rust, paint, grease, or dirt. Unlike traditional methods, it operates without chemicals or abrasives, ensuring safety for both the operator and the environment.

Key Features

1. Portability: Compact design makes it easy to use in various locations.

2. High Precision: Targets contaminants without damaging the base material.

3. Eco-Friendly: No need for consumables or harmful chemicals.

4. Versatility: Suitable for metals, ceramics, and other materials.

5. Cost-Efficiency: Reduces labor and material costs over time.

How Does the Hand Held Laser Cleaner Work?

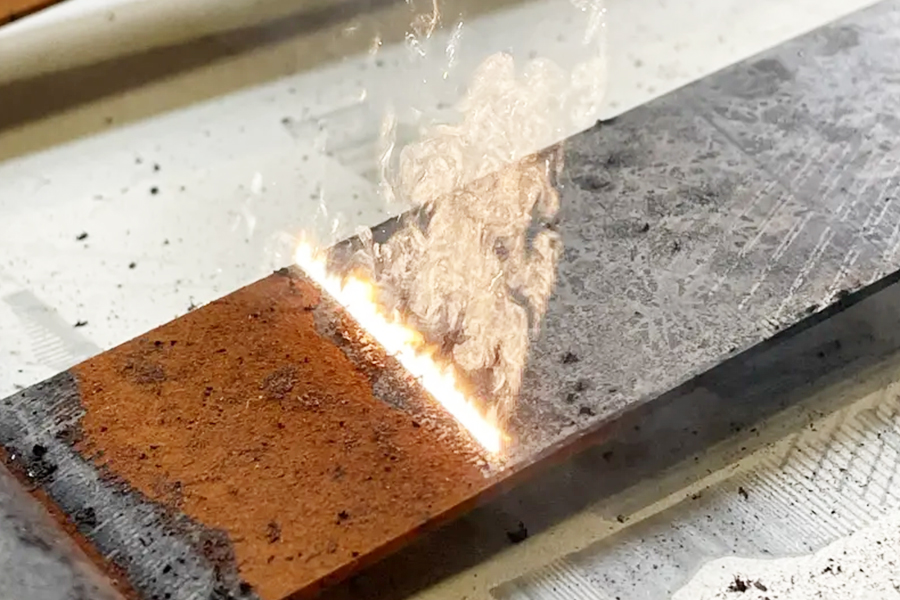

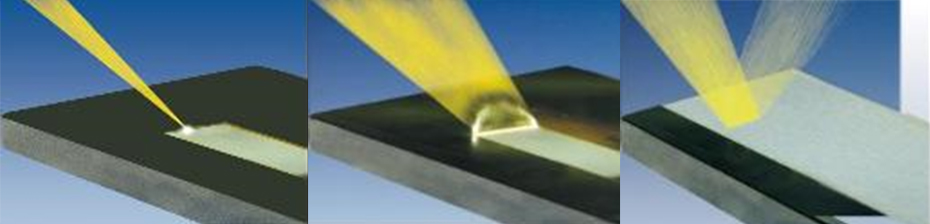

The device operates on the principle of laser ablation, where focused laser beams interact with contaminants on a surface. This interaction causes the contaminants to evaporate or disintegrate, leaving the underlying material intact.

Technical Insights

1. Selective Absorption: Lasers target specific contaminants based on their absorption characteristics.

2. Thermal Effect: High energy breaks down rust, paint, or grease into harmless particles.

3. Non-Contact Cleaning: Ensures no mechanical damage to delicate surfaces.

Applications of Hand Held Laser Cleaners

1. Rust Removal

Effortlessly eliminate rust from machinery, tools, and metal surfaces, restoring them to their original state.

2. Paint Stripping

Remove paint layers from vehicles, industrial equipment, or walls without damaging the base material.

3. Surface Preparation

Prepare surfaces for welding, coating, or adhesive bonding by ensuring a contaminant-free area.

4. Heritage Conservation

Delicately clean sculptures, artifacts, and historical monuments without causing erosion.

5. Electronics Manufacturing

Clean sensitive components, ensuring optimal performance in circuits and devices.

Advantages of Using a Hand Held Laser Cleaner

1. Precision and Control

Offers unparalleled accuracy, making it suitable for intricate or high-value surfaces.

2. Eco-Friendly and Safe

No chemicals or abrasives are required, minimizing environmental impact and health risks.

3. Cost-Effective

Reduces long-term operational costs by eliminating consumables and reducing labor.

4. Versatile Applications

Handles a wide range of materials and industries, from heavy machinery to delicate artifacts.

5. Minimal Downtime

Quick cleaning with no drying time ensures minimal disruption to workflows.

Key Considerations When Choosing a Hand Held Laser Cleaner

1. Power Output

Higher wattage models clean faster and handle tougher contaminants but may not be necessary for all applications.

2. Material Compatibility

Ensure the device supports the materials you work with, such as stainless steel, aluminum, or ceramics.

3. Portability Requirements

Opt for lightweight models if frequent transportation is necessary.

4. User Experience

Look for intuitive controls and easy setup to maximize productivity.

5. After-Sales Support

Choose a manufacturer offering robust warranties, training, and spare parts availability.

Hand Held Laser Cleaners vs. Traditional Cleaning Methods

Chemical Cleaning

• Advantages: Effective for specific contaminants.

• Disadvantages: Involves hazardous chemicals and requires waste disposal.

Abrasive Cleaning

• Advantages: Suitable for large-scale operations.

• Disadvantages: Can damage surfaces and generate significant waste.

Hand Held Laser Cleaning

• Advantages: Precise, non-damaging, and eco-friendly.

• Disadvantages: Higher initial investment but superior long-term value.

Cost of Hand Held Laser Cleaners

The price of a hand held laser cleaner ranges from $10,000 to $40,000, depending on features, power output, and manufacturer.

Cost Factors

1.Power Output: Higher wattage models offer faster results but cost more.

2. Additional Features: Systems with automation or enhanced cooling systems may have a higher price tag.

3. Customizations: Tailored solutions for specific applications can increase costs.

Hidden Costs

• Training and Installation: Some providers charge separately for these services.

• Maintenance: Routine upkeep ensures optimal performance and longevity.

FAQs About Fiber Laser Cleaning

Q1: Are hand held laser cleaners safe to use?

Yes, when used with proper safety equipment like protective eyewear, they are highly safe.

Q2: Can they clean all types of surfaces?

While effective on metals, testing is recommended for sensitive materials like wood or fabric.

Q3: What industries benefit the most from this technology?

Industries such as automotive, aerospace, electronics, and restoration see significant advantages.

Q4: How long does a laser cleaning device last?

With regular maintenance, these devices can last over 50,000 operational hours.

The Future of Hand Held Laser Cleaning Technology

As technology advances, hand held laser cleaners are becoming more efficient, affordable, and accessible. Innovations include:

• AI Integration: Smarter systems for automated cleaning.

• Compact Designs: Enhancing portability and usability.

• Cost Efficiency: Reductions in production costs will make these devices more affordable for a wider audience.

Why Invest in a Hand Held Laser Cleaner?

Whether you’re in industrial manufacturing, historical restoration, or everyday maintenance, a hand held laser cleaner offers unparalleled precision, efficiency, and eco-friendliness. It’s a game-changing tool that transforms cleaning processes, delivering exceptional results while reducing environmental impact and operational costs.