Fiber Laser Cleaning Machine Price: What You Need to Know

When it comes to industrial cleaning, fiber laser cleaning machine price often becomes a deciding factor. The technology’s efficiency, precision, and eco-friendly approach have made it indispensable across industries. But understanding its cost and the factors influencing it is crucial for businesses aiming to invest in sustainable solutions.

What is a Fiber Laser Cleaning Machine?

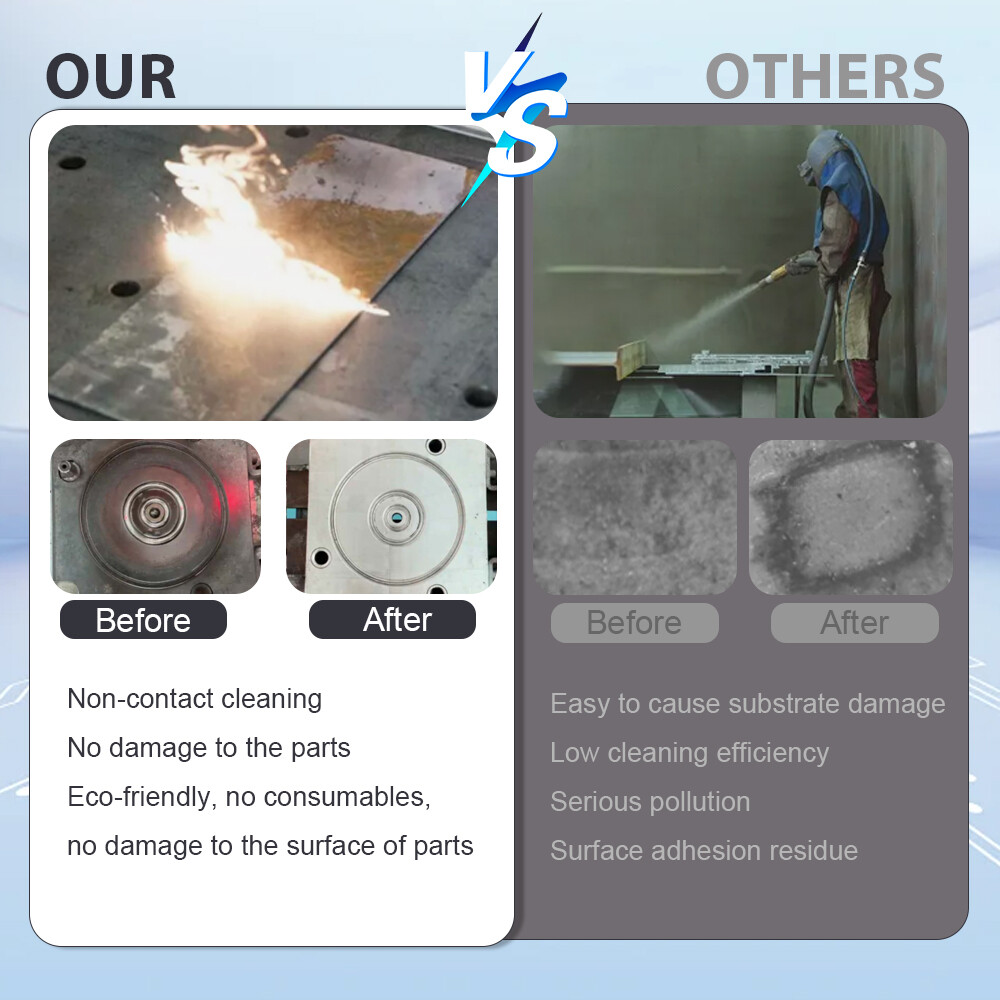

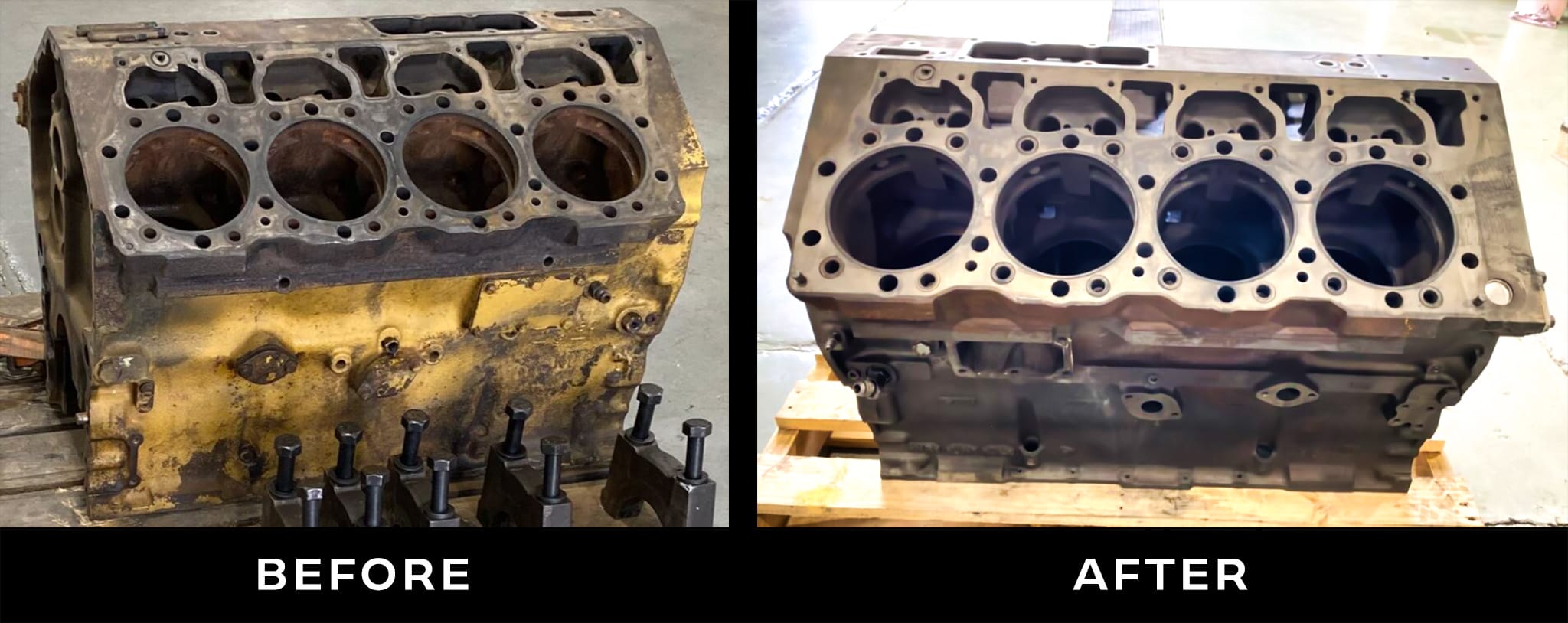

Fiber laser cleaning machines use high-energy laser beams to remove contaminants like rust, paint, grease, and oxide layers from various surfaces. This cutting-edge technology has redefined industrial cleaning by offering a non-contact, efficient, and environmentally friendly solution.

How Does It Work?

1. Laser Emission: A focused laser beam is projected onto the surface.

2. Absorption: Contaminants absorb the laser energy, breaking their molecular bonds.

3. Vaporization or Ablation: The residue is vaporized or gently blown away, leaving a pristine surface.

Factors Influencing Fiber Laser Cleaning Machine Price

1. Laser Power

Higher power levels, such as 100W, 200W, or even 1000W, significantly impact the cost. Higher power ensures faster and more effective cleaning but comes at a premium.

2. Advanced Features

Machines equipped with features like automation, touchscreen controls, and AI-based adjustments have higher price tags due to enhanced usability and efficiency.

3. Portability

Portable machines, while convenient, may cost more due to their compact design and advanced engineering.

4. Durability and Build Quality

Premium materials and robust construction influence both the performance and longevity of the machine, affecting the price.

5. Customization Options

Some manufacturers offer tailored machines for specific industries, which may increase the cost.

Typical Fiber Laser Cleaning Machine Prices

| Laser Power | Approximate Price Range |

|---|---|

| 50W | $10,000 - $20,000 |

| 100W | $20,000 - $30,000 |

| 200W | $30,000 - $50,000 |

| 500W and above | $50,000 - $100,000+ |

Prices may vary based on additional features, warranty, and manufacturer reputation.

Why Invest in Fiber Laser Cleaning Machines?

1. Efficiency

These machines deliver unparalleled precision, cleaning surfaces without damaging the base material.

2. Environmentally Friendly

Unlike traditional methods, fiber lasers eliminate the need for harmful chemicals, making them eco-conscious solutions.

3. Cost-Effective in the Long Run

Though the initial investment may seem steep, the savings in consumables and reduced labor make it a wise choice.

4. Versatile Applications

From automotive and aerospace to cultural heritage preservation, the uses are limitless.

Applications of Fiber Laser Cleaning Machines

1. Automotive Sector

Remove rust and paint from metal parts, ensuring longevity and performance.

2. Aerospace Industry

Maintain the integrity of delicate components by using non-invasive cleaning methods.

3. Cultural Preservation

Restore artifacts and sculptures without damaging their historical value.

4. Manufacturing and Heavy Industries

Clean molds, tools, and machinery parts efficiently.

Comparing Fiber Laser Cleaning to Traditional Methods

| Feature | Fiber Laser Cleaning | Traditional Methods |

|---|---|---|

| Environmental Impact | Minimal | High |

| Precision | High | Moderate |

| Maintenance Needs | Low | Moderate to High |

| Consumables | None | Chemicals, abrasives |

How to Choose the Right Fiber Laser Cleaning Machine

1. Assess Your Needs: Determine the type and volume of cleaning required.

2. Check Specifications: Focus on laser power, portability, and additional features.

3. Compare Prices: Research multiple vendors to get the best value for money.

4. Warranty and Support: Opt for machines with extended warranties and reliable customer support.

5. Consider Future Scalability: Choose a machine that can handle potential increases in workload.

Future Trends in Fiber Laser Cleaning Technology

1. AI Integration: Smarter machines that adapt settings to material type and contamination level.

2. Lower Costs: Advances in manufacturing are expected to reduce prices.

3. Energy Efficiency: Next-gen machines will consume less power while delivering higher output.

4. Broader Applications: Expanding use cases, including medical equipment and renewable energy sectors.

Maintenance Tips for Fiber Laser Cleaning Machines

1. Regular Cleaning: Ensure the laser head is free from dust and debris.

2. Routine Inspections: Check for wear and tear in components.

3. Proper Storage: Store the machine in a clean and dry environment.

4. Operator Training: Train staff to use the machine efficiently and safely.

Conclusion (Not using the word explicitly)

Fiber laser cleaning machines are transforming industries by offering precise, eco-friendly, and efficient solutions. While the price might seem like a hurdle, the long-term benefits far outweigh the initial investment. By understanding the factors affecting the cost and how to choose the right machine, businesses can make informed decisions that align with their operational goals. Whether you’re in manufacturing, restoration, or maintenance, a fiber laser cleaning machine is a game-changer for achieving superior results.