Unveiling the Precision of Fiber Laser Cleaner Technology

In the world of cleaning, where precision meets innovation, fiber laser cleaner stands as a beacon of technological advancement. Imagine a method that eliminates rust, paint, and contaminants with unparalleled accuracy, leaving the surface untouched and the environment unharmed.

What is a Fiber Laser Cleaner?

A fiber laser cleaner is a cutting-edge device that utilizes fiber laser technology to remove rust, paint, grease, and other contaminants from various surfaces. Unlike traditional cleaning methods, it provides non-contact, eco-friendly, and highly efficient cleaning solutions.

How Fiber Laser Cleaning Works

1. Emission: A focused laser beam is directed at the contaminated surface.

2. Absorption: The contaminants absorb the laser energy, causing them to disintegrate.

3. Evaporation or Ablation: Residues are vaporized or blown away, revealing a pristine surface.

Advantages of Fiber Laser Cleaner

1. Precision Cleaning

Fiber lasers target only the contaminants, leaving the base material unaffected.

2. Eco-Friendly Solution

Say goodbye to chemical waste and environmental hazards. Fiber laser cleaning generates minimal residue and requires no toxic chemicals.

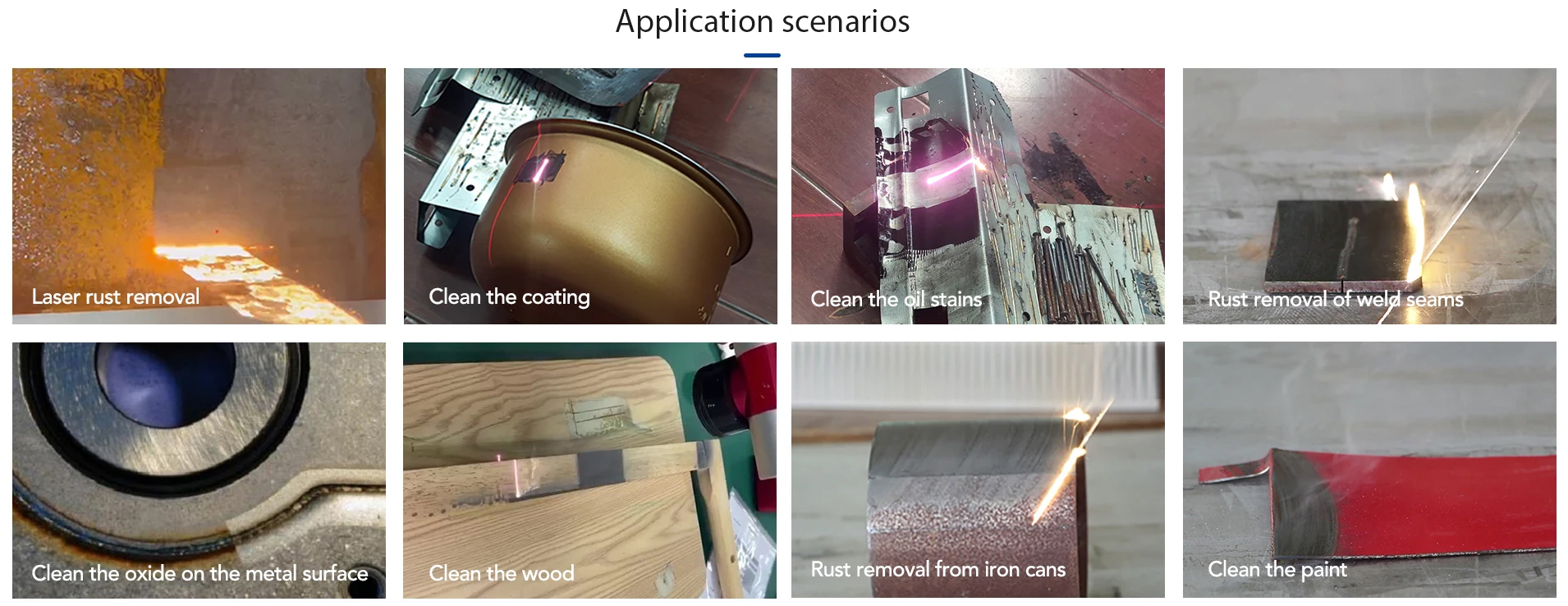

3. Versatile Applications

From automotive restoration to historical artifact preservation, fiber lasers adapt to a myriad of cleaning needs.

4. Cost-Effective

Although the initial cost is higher, the long-term savings on consumables and labor make it a smart investment.

5. Time-Saving

Fiber laser cleaning is significantly faster than traditional cleaning methods, boosting productivity.

Applications of Fiber Laser Cleaner

1. Automotive Industry

Fiber lasers remove rust and paint from vehicle components with unparalleled precision.

2. Aerospace Maintenance

Delicate parts require non-invasive cleaning, making fiber lasers the ideal choice.

3. Marine Industry

Rust and corrosion removal from ships and offshore equipment become efficient and hassle-free.

4. Historical Preservation

Artifacts can be cleaned without damaging their original integrity.

5. Industrial Maintenance

Heavy machinery benefits from precise cleaning, prolonging its operational lifespan.

Understanding the Cost of Fiber Laser Cleaners

The price of a fiber laser cleaner can range between $10,000 to $60,000, depending on factors such as:

1. Laser Power: Higher power translates to faster cleaning but comes at a premium.

2. Features: Portability, automation, and advanced safety measures influence pricing.

3. Brand and Warranty: Reputable manufacturers may charge more for quality assurance.

While the upfront cost may seem steep, the low operational expenses and efficiency make it a worthwhile investment.

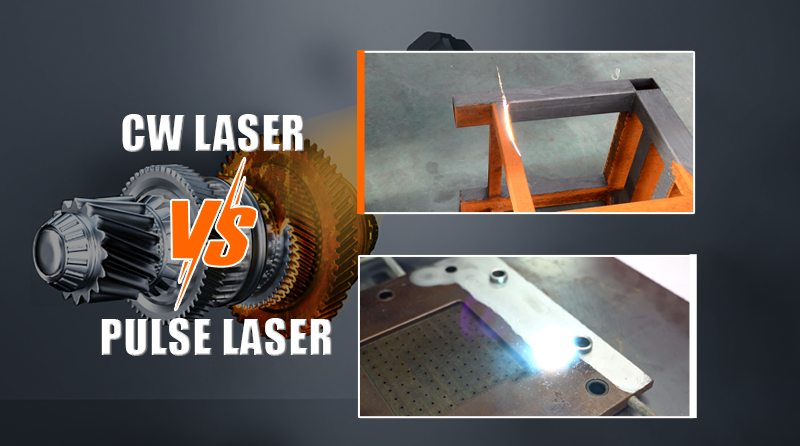

Fiber Laser Cleaner vs Traditional Cleaning Methods

| Feature | Fiber Laser Cleaner | Traditional Methods |

|---|---|---|

| Environmental Impact | Minimal | High |

| Precision | High | Moderate |

| Operational Costs | Low | High |

| Maintenance Needs | Low | Moderate to High |

Innovations in Fiber Laser Cleaner Technology

1. AI Integration

Smart lasers adjust settings based on the surface material and contamination type.

2. Compact Designs

Portable models allow for on-site cleaning, reducing transportation costs and downtime.

3. Enhanced Safety Features

Automatic shutdowns and protective barriers ensure operator safety.

4. Multi-Material Capability

Modern fiber lasers can clean metals, plastics, and even delicate surfaces without causing damage.

Future Trends in Fiber Laser Cleaning

1. Increased Affordability: As technology advances, prices are expected to drop, making fiber lasers more accessible.

2. Wider Applications: Expanding into fields like medical equipment cleaning and food processing.

3. Energy Efficiency: Next-generation lasers will consume less power while delivering higher performance.

4. Robotics Integration: Automated systems will enhance precision and efficiency in industrial cleaning.

Safety and Maintenance Tips for Fiber Laser Cleaners

1. Wear Protective Gear: Use safety goggles and gloves during operation.

2. Ensure Proper Ventilation: Prevent the inhalation of vaporized contaminants.

3. Regular Maintenance: Clean the laser head and check for any damage to ensure longevity.

4. Operator Training: Proper training minimizes risks and maximizes efficiency.

Why Choose Fiber Laser Cleaners?

Fiber laser cleaners represent the pinnacle of cleaning technology. With unmatched precision, eco-friendliness, and efficiency, they are setting new standards across industries. Whether you’re restoring a classic car, maintaining industrial equipment, or preserving history, a fiber laser cleaner delivers results that no other method can match.