Exploring the Cost of Laser Welders: A Comprehensive Guide

The cost of laser welder systems is a topic of great interest to industries seeking precision and efficiency. Laser welding has become an essential technology for sectors ranging from automotive to aerospace, delivering impeccable performance with reduced material waste. Understanding the financial aspects of these systems is vital for businesses aiming to optimize their manufacturing processes. This guide will delve into the pricing structure, factors influencing costs, and the long-term value of laser welders.

Why Does the Cost of Laser Welders Matter?

The cost of laser welding equipment often reflects its capabilities, durability, and application range. While the initial investment might seem high, the long-term benefits—such as precision, speed, and energy efficiency—justify the expense. Businesses investing in laser welders often experience increased productivity, reduced material wastage, and lower labor costs, leading to substantial savings over time.

Key Factors Influencing the Cost of Laser Welders

1. Power Output and Type

Laser welders come in various power ranges, typically measured in watts. Higher power models can weld thicker materials and often come with a higher price tag. Additionally, the type of laser—fiber, CO2, or diode—also impacts the cost due to differences in technology and efficiency.

2. Automation Level

Automated systems equipped with robotics or CNC integration tend to cost more than manual or semi-automatic options. However, automation significantly enhances accuracy and reduces operational errors, providing a higher return on investment.

3. Material Compatibility

Systems designed for a broad range of materials, including metals and polymers, may be priced higher due to their versatility and advanced technology.

4. Brand and Manufacturer

While this guide avoids discussing specific brands, the reputation and reliability of the manufacturer often play a role in pricing. Trusted manufacturers may charge a premium for their proven track record and customer support.

5. Additional Features

Cooling systems, beam quality, portability, and user-friendly software interfaces contribute to the overall cost. Advanced features can streamline operations and enhance efficiency, making them worthwhile for many users.

Typical Price Ranges

Laser welders come in a wide range of prices, depending on their features and applications:

• Entry-Level Systems: Designed for smaller-scale operations or hobbyists, these welders range from $10,000 to $50,000.

• Mid-Range Models: Suitable for small to medium-sized businesses, these systems cost between $50,000 and $150,000.

• High-End Industrial Machines: Advanced systems for heavy-duty applications can exceed $500,000.

Cost vs. Value: Is a Laser Welder Worth It?

While the upfront cost of laser welders might seem significant, their long-term benefits often outweigh the initial investment. Key advantages include:

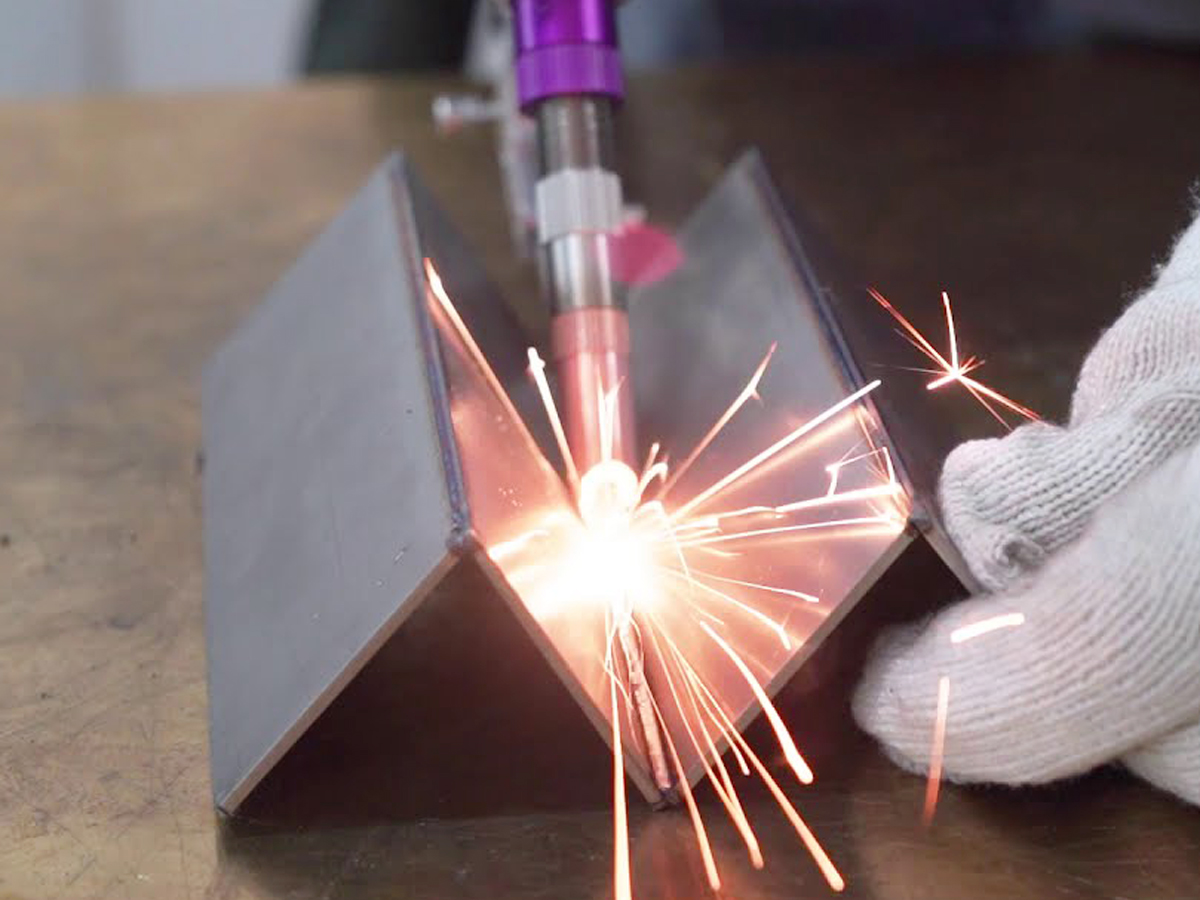

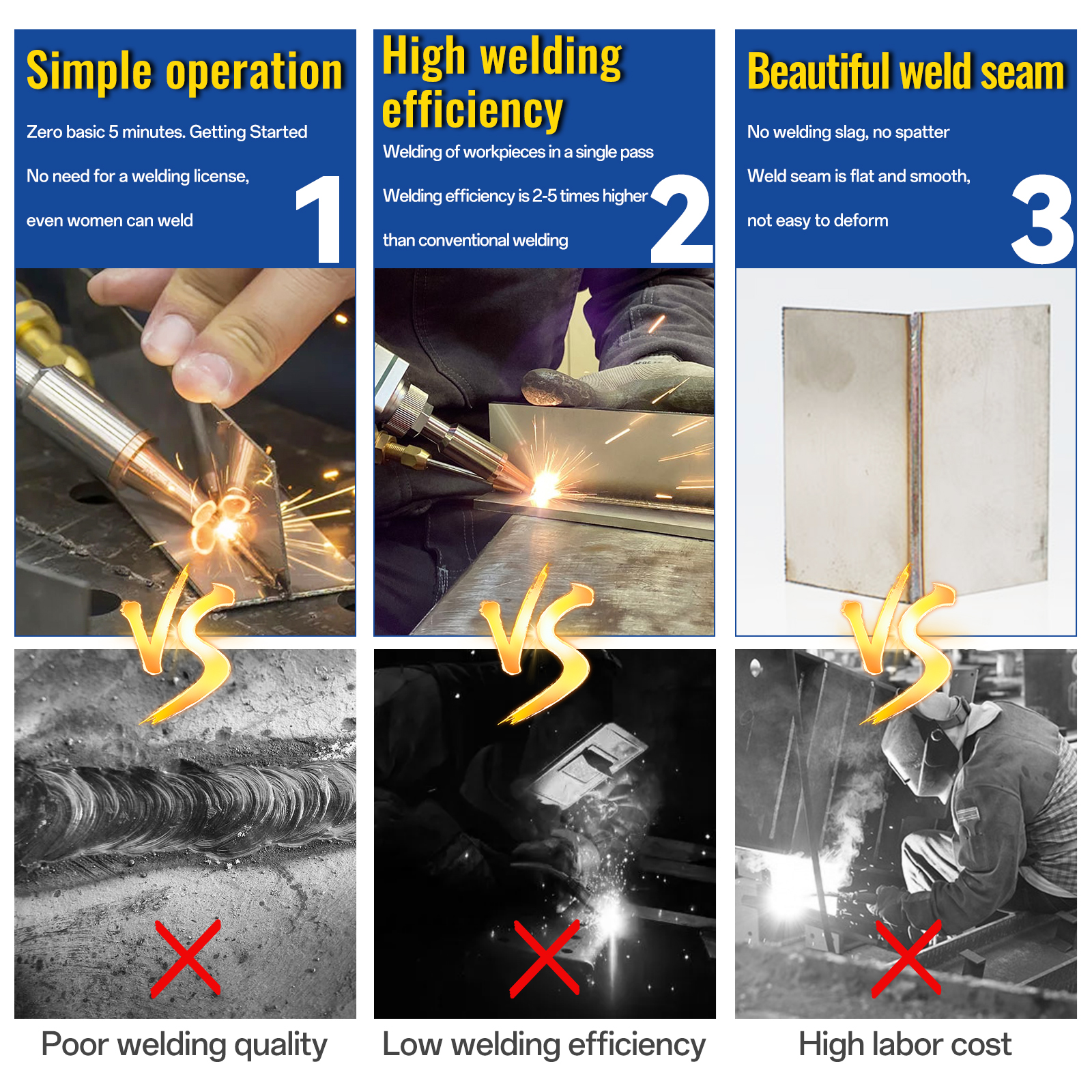

• Precision: Laser welders create clean, accurate welds with minimal distortion, reducing material waste.

• Efficiency: Faster welding speeds and automation capabilities translate to higher productivity.

• Versatility: The ability to work with various materials increases flexibility in manufacturing.

• Reduced Labor Costs: Automation minimizes the need for manual intervention, lowering labor expenses.

Industries Benefiting from Laser Welders

Automotive Manufacturing

Laser welding is used extensively for creating lightweight, durable components, improving vehicle efficiency and safety.

Medical Device Production

Precision and cleanliness are critical for medical instruments, making laser welders an ideal choice.

Aerospace Engineering

In aerospace, where material integrity is paramount, laser welding ensures strong and reliable joints.

Electronics

Laser welders are perfect for assembling delicate electronic components, ensuring durability and functionality.

How to Choose the Right Laser Welder

Step 1: Assess Your Needs

Identify the materials, thicknesses, and production volumes your business requires.

Step 2: Compare Features

Look for systems with adjustable power, automation options, and versatile material compatibility.

Step 3: Calculate Long-Term Value

Consider the potential savings from reduced waste, lower labor costs, and increased efficiency.

Step 4: Consult Industry Experts

Engage with professionals or experienced users to ensure your chosen system meets your needs.

Tips for Reducing Costs

Buy Used or Refurbished Machines

Pre-owned laser welders can provide high performance at a fraction of the cost.

Opt for Modular Designs

Choose systems with upgradable components to future-proof your investment.

Explore Financing Options

Many manufacturers offer leasing or financing plans to make high-end systems more accessible.

Maintenance and Operating Costs

Beyond the initial purchase, it’s essential to consider ongoing expenses, including:

• Energy Consumption: Efficient models can reduce electricity costs significantly.

• Maintenance: Regular upkeep, including cleaning optics and inspecting cooling systems, ensures longevity.

• Training: Investing in operator training minimizes errors and maximizes productivity.

Future Trends Impacting Laser Welder Costs

The laser welding industry continues to evolve, with trends such as:

• AI Integration: Advanced software optimizes performance and reduces operator input.

• Green Manufacturing: Eco-friendly technologies lower energy consumption and environmental impact.

• Customization: Tailored solutions for specific industries are becoming more accessible.

Investing in a laser welder is not just a purchase—it’s a strategic decision that can transform your business operations. By understanding the cost of laser welder systems and evaluating your specific needs, you can make an informed choice that delivers long-term value.