Introduction

Laser cleaning equipment is reshaping industries with unparalleled efficiency, precision, and eco-friendliness. Whether it’s rust removal, paint stripping, or delicate restoration, laser cleaning stands as a cutting-edge solution for businesses looking to innovate while reducing environmental impact. This in-depth guide covers everything you need to know about laser cleaning equipment: its workings, applications, benefits, and the transformative impact it has on industries worldwide. Dive in to discover how this groundbreaking technology is paving the way for a cleaner, greener, and more advanced future.

1. Understanding Laser Cleaning Equipment

At its core, laser cleaning equipment is a non-contact, high-precision tool that removes unwanted substances like rust, grease, or paint from surfaces. Unlike traditional cleaning methods, which often involve abrasive materials or harmful chemicals, laser cleaning leverages focused laser beams for an eco-friendly and efficient process.

How It Works:

• Laser Beam Emission:A high-intensity laser beam is directed onto the contaminated surface.

• Absorption and Vaporization:The contaminants absorb the laser’s energy, heating up and vaporizing without damaging the underlying material.

• Non-Invasive Process:The equipment ensures no abrasion or mechanical force, making it ideal for sensitive surfaces.

Key Features:

• High Precision:Perfect for intricate or delicate surfaces.

• Eco-Friendly:No chemical waste or secondary pollutants.

• Versatility:Works on various materials, including metals, plastics, and stone.

2. Applications Across Industries

Laser cleaning equipment is versatile and finds applications in a wide array of industries. Its adaptability and precision make it a go-to solution for diverse cleaning and preparation tasks.

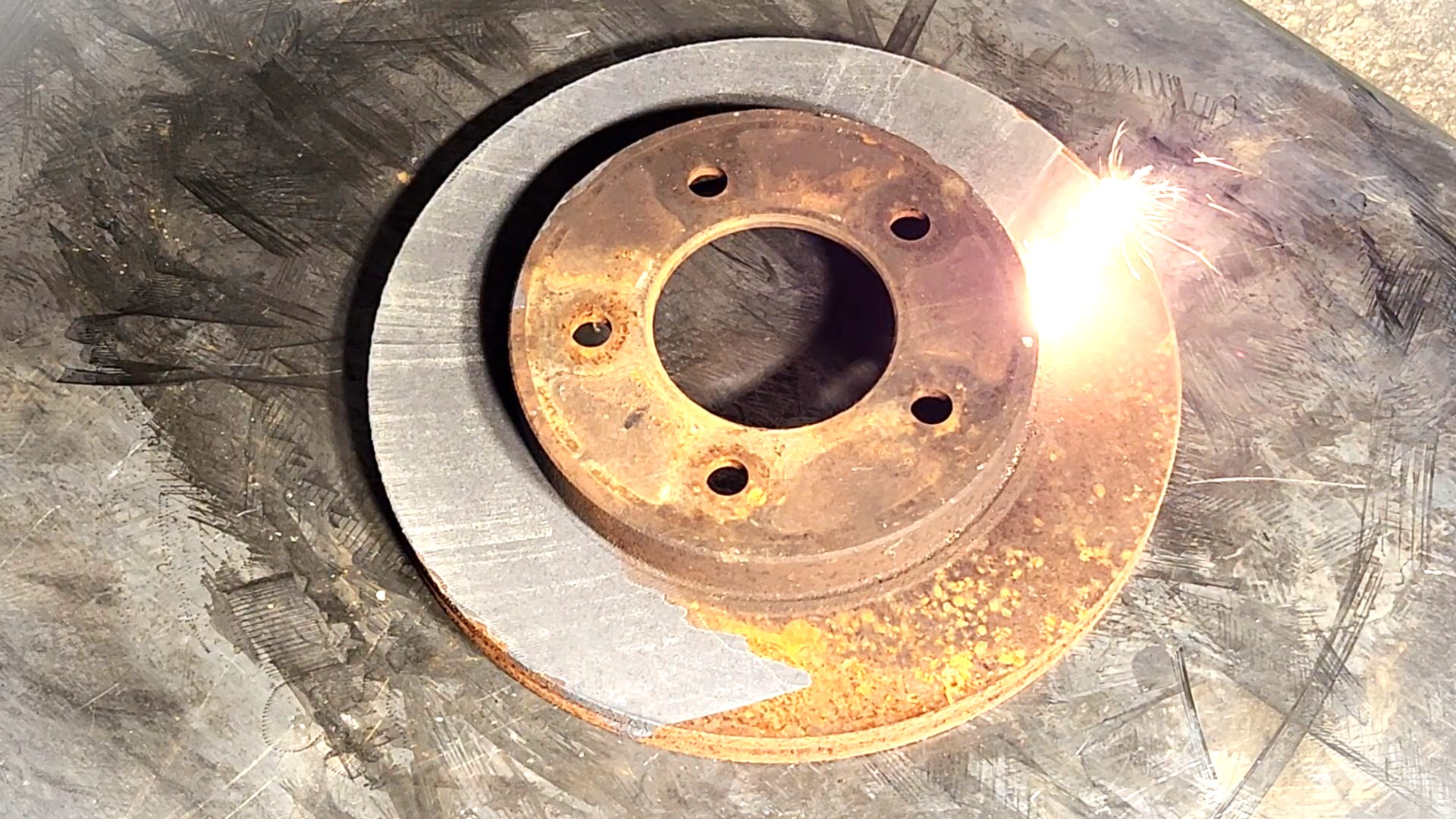

Automotive Industry:

• Rust and Paint Removal:Essential for refurbishing car parts and body panels.

• Mold Cleaning:Ensures precision and quality in automotive manufacturing.

Aerospace Sector:

• Surface Preparation:Crucial for applying protective coatings.

• Component Cleaning:Removes grease, oxides, and residues from sensitive parts.

Electronics Manufacturing:

• Precision Cleaning:Ideal for delicate components and micro-circuits.

• Oxide Removal:Ensures optimal performance in semiconductors and circuit boards.

Cultural Heritage Restoration:

• Non-Invasive Cleaning:Safely restores monuments, sculptures, and artworks.

• Gentle Surface Treatment:Preserves the integrity of historic materials.

Energy Sector:

• Pipeline Maintenance:Removes rust and corrosion for improved safety.

• Solar Panel Cleaning:Enhances energy efficiency by removing dirt and debris.

3. Benefits of Laser Cleaning Equipment

Laser cleaning equipment is transforming how industries approach cleaning and surface preparation. Its numerous benefits ensure it stands out from traditional methods.

Eco-Friendly and Sustainable:

• Eliminates the use of chemicals, reducing environmental harm.

• Produces no secondary waste, making it a zero-waste cleaning option.

Cost-Effective:

• Reduces dependency on consumables like solvents and abrasives.

• Lowers maintenance costs and increases operational efficiency.

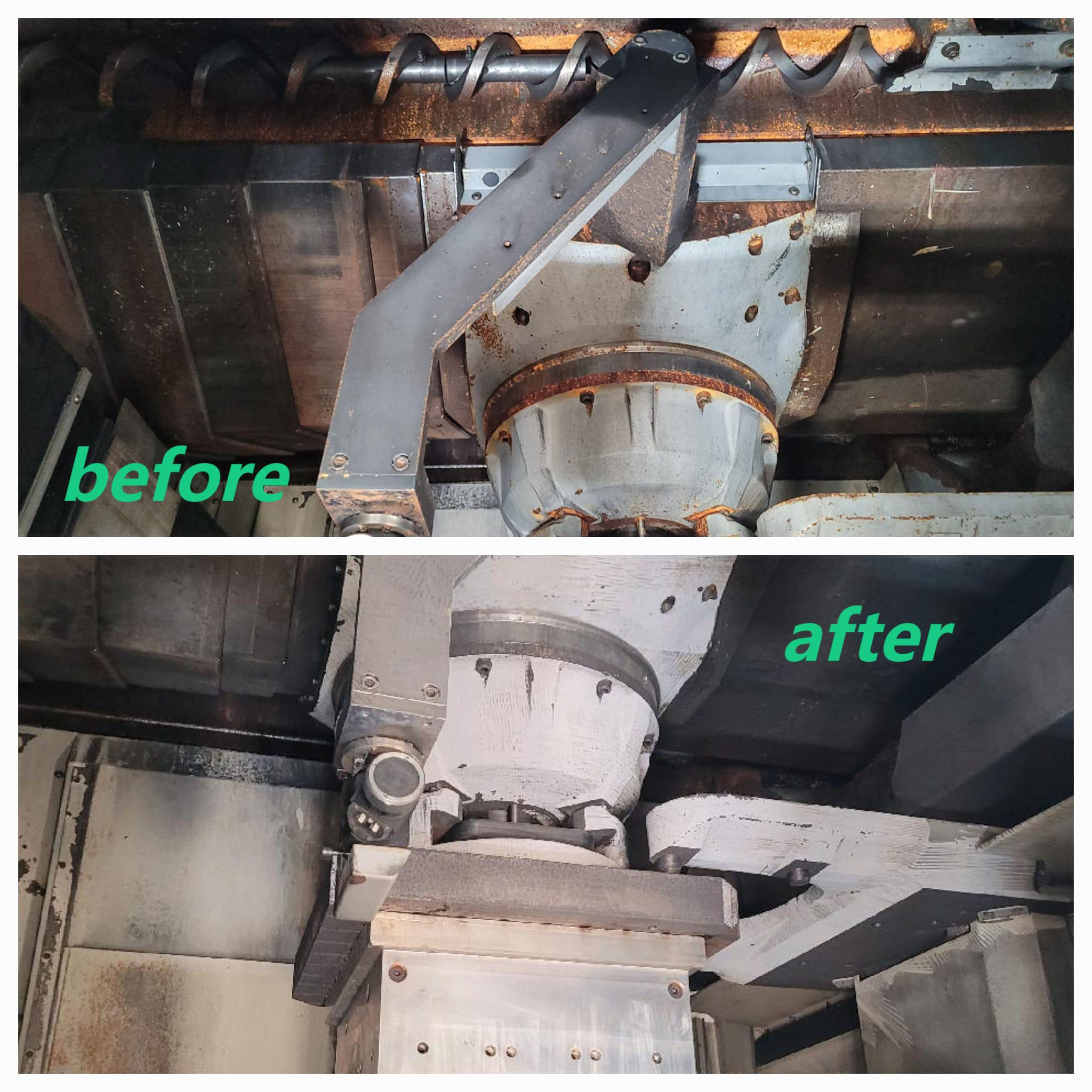

High Efficiency:

• Operates at faster speeds compared to conventional cleaning methods.

• Removes contaminants without damaging underlying materials.

Enhanced Precision:

• Adjusts to intricate patterns and complex geometries.

• Ideal for delicate surfaces requiring minimal impact.

4. Selecting the Right Laser Cleaning Equipment

Choosing the right laser cleaning equipment involves understanding your specific requirements, including material type, cleaning intensity, and operational settings.

Key Factors to Consider:

1. Laser Power:

° Low-power lasers for delicate tasks like electronics cleaning.

° High-power lasers for industrial applications like rust removal.

2.Portability:

° Compact and handheld models for on-site tasks.

° Stationary units for large-scale industrial operations.

3.Control Features:

° Advanced settings to customize beam focus and intensity.

° User-friendly interfaces for simplified operation.

4.Safety Features:

° Equipment with integrated safety measures like enclosures and automatic shut-offs.

5. Innovations in Laser Cleaning Technology

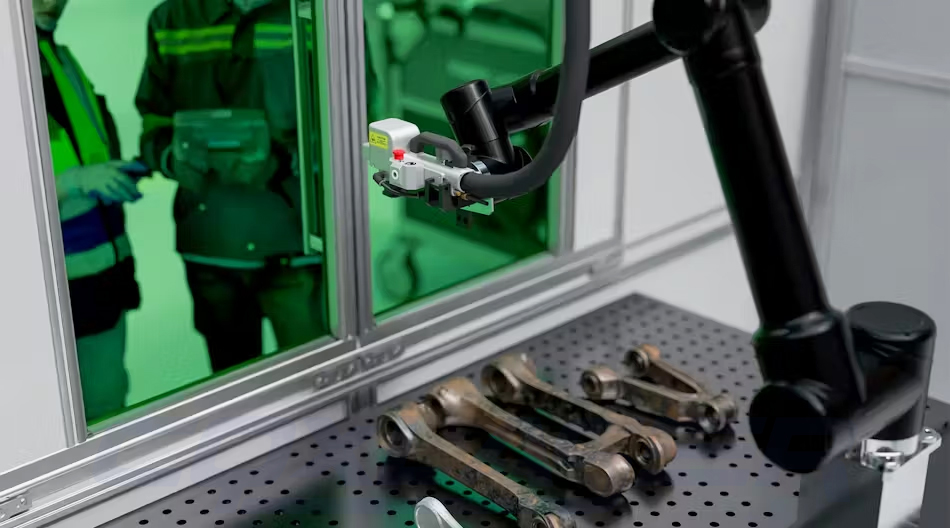

The future of laser cleaning technology is marked by advancements that enhance its efficiency, accessibility, and versatility.

Emerging Trends:

• Automation and Robotics:Integration with robotic systems for automated cleaning processes.

• AI-Driven Precision:AI algorithms enabling adaptive cleaning based on surface conditions.

• Portable Solutions:Development of lightweight, compact devices for field operations.

Future Potential:

• Expanding into newer industries like medical device manufacturing and renewable energy.

• Enhanced compatibility with eco-conscious manufacturing practices.

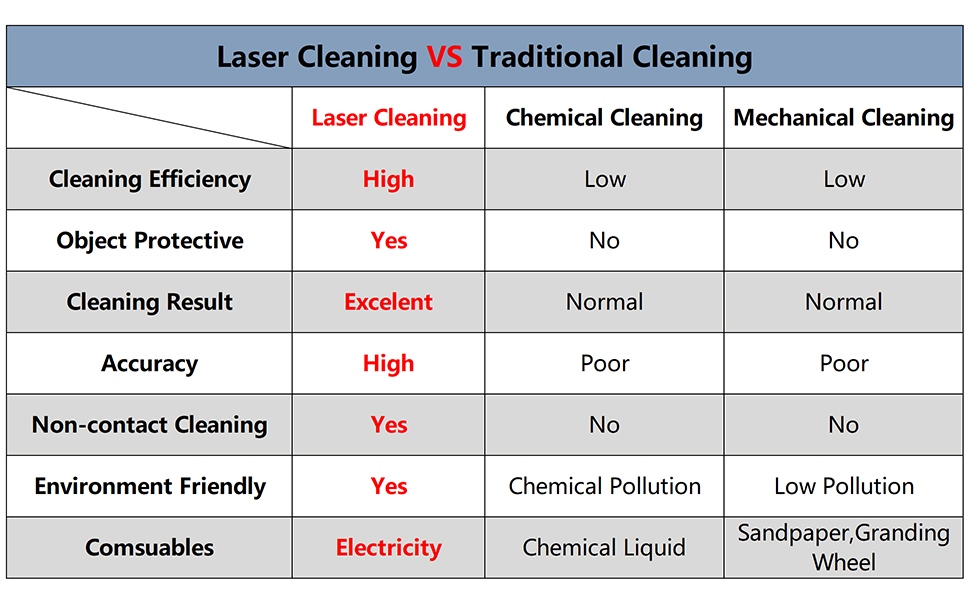

6. Comparing Laser Cleaning to Traditional Methods

When compared to traditional cleaning methods, laser cleaning equipment offers unmatched advantages in terms of efficiency, safety, and environmental impact.

Traditional Methods:

• Use of abrasive materials or harsh chemicals.

• Generates secondary waste and poses disposal challenges.

• Risk of damaging surfaces during cleaning.

Laser Cleaning:

• Non-contact and non-abrasive, preserving surface integrity.

• No chemicals or waste, ensuring eco-friendliness.

• High precision, enabling detailed and delicate work.

7. Practical Use Cases of Laser Cleaning

Laser cleaning equipment has been successfully adopted in various scenarios, showcasing its adaptability and effectiveness.

Industrial Maintenance:

• Cleaning heavy machinery and equipment.

• Removing old coatings and preparing surfaces for new applications.

Restoration Projects:

• Removing graffiti and stains from historic buildings.

• Cleaning oxidized metals in antique restoration.

Scientific Research:

• Cleaning laboratory equipment to ensure experimental accuracy.

• Preparing samples for high-precision analysis.

8. FAQs About Laser Cleaning Equipment

To better understand laser cleaning equipment, here are answers to some common questions:

Q1: Is laser cleaning safe?

Yes, modern laser cleaning equipment is designed with safety features to protect operators. Proper training and protective gear ensure safe usage.

Q2: What materials can be cleaned with lasers?

Laser cleaning works on metals, plastics, ceramics, and even stone surfaces.

Q3: How long does laser cleaning take?

The time required depends on the size of the area and the level of contamination but is generally faster than traditional methods.

Closing Thoughts

Laser cleaning equipment represents a pivotal shift toward eco-friendly and efficient cleaning solutions. Its ability to combine precision, speed, and sustainability makes it indispensable across industries. Whether you’re preparing surfaces for advanced coatings, restoring historic artifacts, or cleaning industrial machinery, laser cleaning offers unparalleled advantages. By adopting this technology, businesses not only boost operational efficiency but also contribute to a greener, more sustainable future. Explore the possibilities of laser cleaning today and transform your cleaning processes for the better.