The Revolution of Manufacturing: 3 in 1 Laser Welding Machine

The 3 in 1 laser welding machine is reshaping industrial operations, blending precision, versatility, and efficiency in one system. Imagine welding, cutting, and cleaning combined into a single machine that delivers exceptional results with minimal effort. In this article, we explore the technology behind these machines, their benefits, and their impact on various industries.

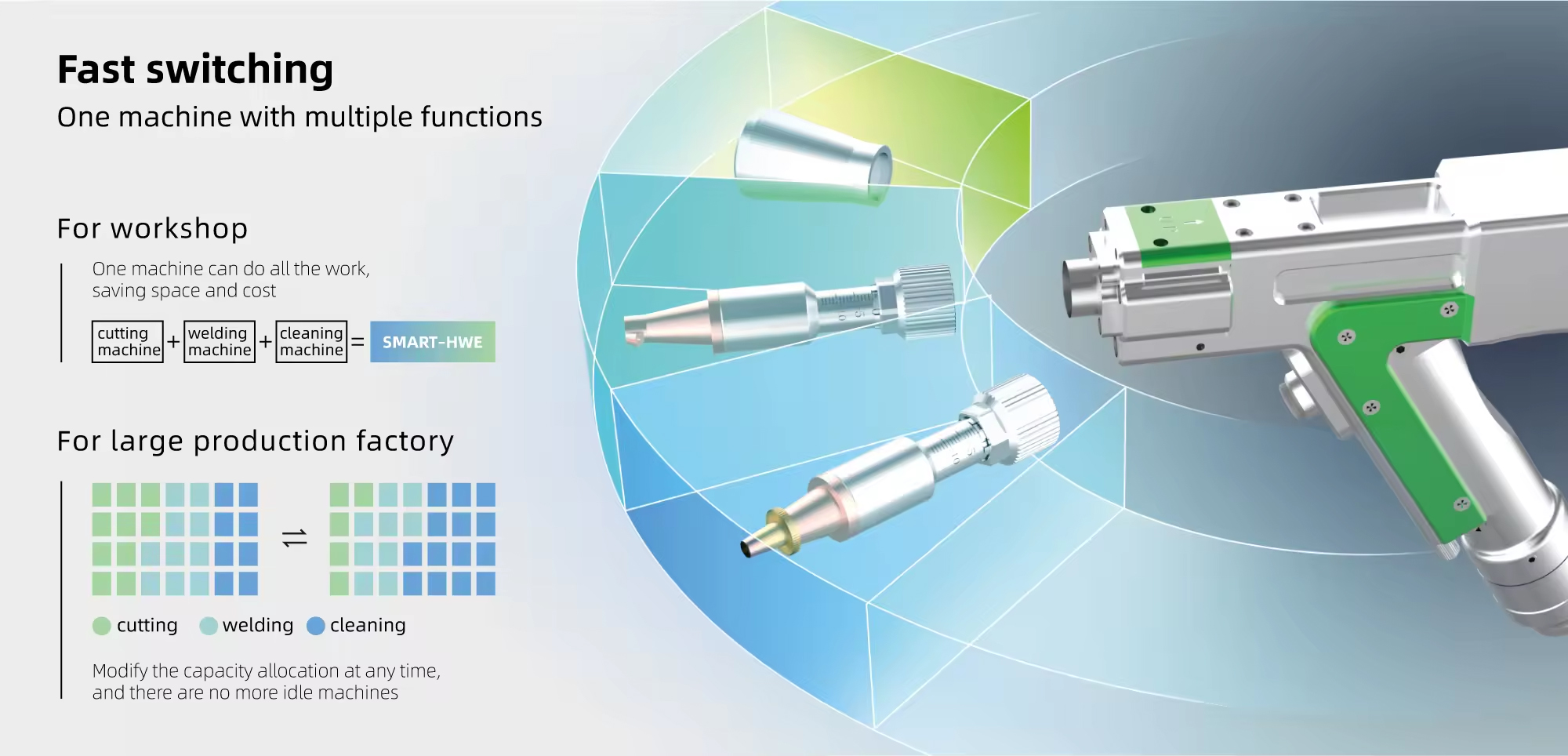

What Is a 3 in 1 Laser Welding Machine?

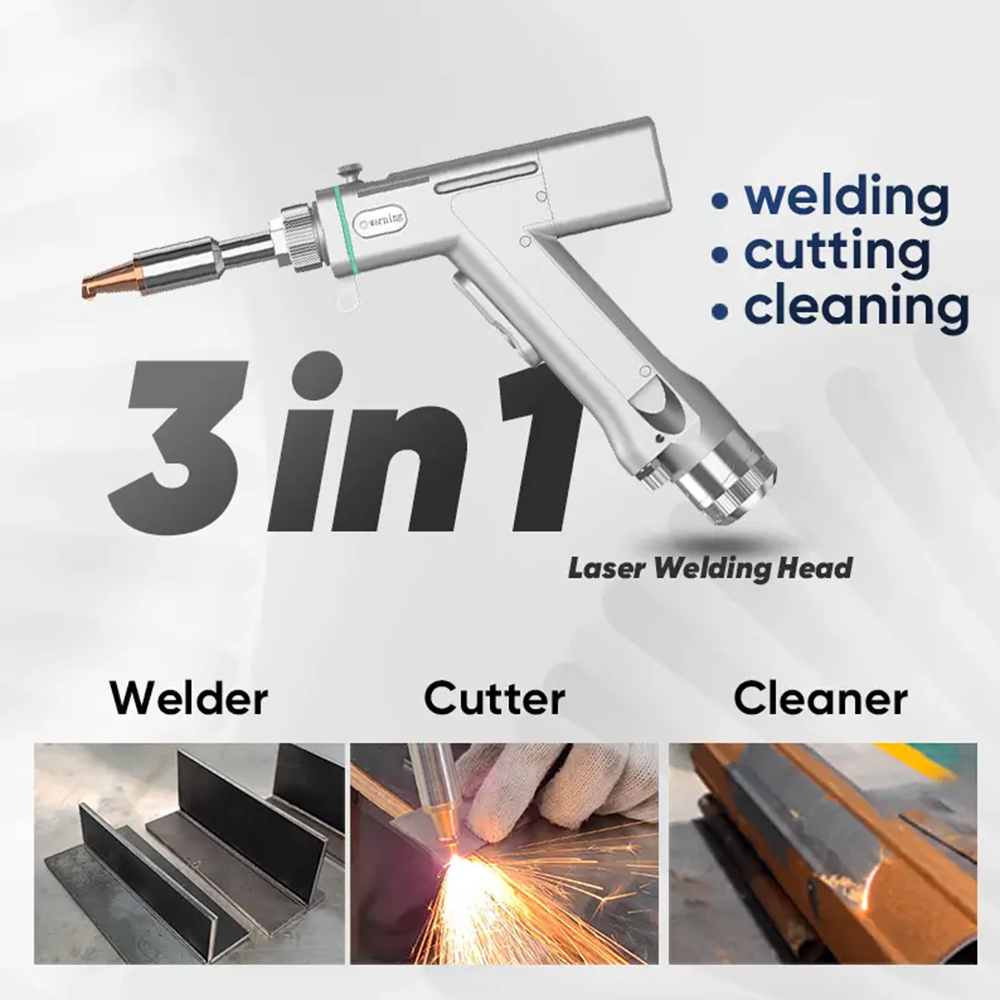

A 3 in 1 laser welding machine integrates three essential functions—laser welding, cutting, and cleaning—into one compact unit. This innovation addresses the diverse needs of industries that require precision and efficiency in metal processing.

Key Features

1. Laser Welding: Creates precise, durable joints with minimal distortion.

2. Laser Cutting: Offers high-speed, accurate cutting for various metal thicknesses.

3. Laser Cleaning: Removes rust, paint, and contaminants, ensuring optimal surface preparation.

How It Works

Using advanced laser technology, these machines harness high-energy beams to perform multiple tasks with unmatched precision. The seamless transition between functions saves time and reduces operational costs.

Benefits of a 3 in 1 Laser Welding Machine

1. Versatility

This all-in-one system supports a wide range of materials, including stainless steel, aluminum, and carbon steel.

2. Cost-Efficiency

Combining three functions into one machine reduces equipment costs and operational downtime.

3. Enhanced Precision

With adjustable settings, the machine ensures accuracy for welding, cutting, and cleaning tasks.

4. Eco-Friendly Operation

Laser cleaning eliminates the need for harmful chemicals, making the process environmentally sustainable.

5. User-Friendly Design

The machine’s intuitive interface simplifies operation, even for those new to laser technology.

Applications Across Industries

1. Automotive Manufacturing

From chassis welding to precision cutting, this machine enhances productivity in automotive assembly lines.

2. Aerospace Engineering

Its ability to handle high-strength materials makes it invaluable for aerospace applications, ensuring lightweight, durable components.

3. Medical Devices

The clean, precise welds and cuts are ideal for creating surgical instruments and implants.

4. Construction

The machine streamlines metal preparation and joining in large-scale infrastructure projects.

5. Electronics

Thin, intricate components in devices benefit from the machine’s high precision and adaptability.

Optimizing the Use of a 3 in 1 Laser Welding Machine

Material Selection

Choose materials compatible with the machine’s laser capabilities to maximize efficiency.

Parameter Settings

Adjust power, speed, and focus to achieve the desired results for welding, cutting, or cleaning.

Maintenance

Regular cleaning of the optical lenses and proper cooling system management ensures optimal performance.

Safety Measures

Use protective eyewear and follow operational guidelines to ensure safety during use.

Challenges and Solutions

1. Initial Investment

While the upfront cost is high, the machine’s long-term savings justify the expense.

2. Technical Training

Solution: Offer comprehensive training programs for operators to maximize the machine’s potential.

3. Maintenance Requirements

Solution: Establish a routine maintenance schedule to avoid unexpected downtime.

Innovations Driving the Future

AI Integration

Real-time monitoring and automated adjustments enhance precision and reduce errors.

Portable Systems

Smaller, mobile units bring 3 in 1 functionality to on-site projects, expanding their application range.

Energy Efficiency

Advancements in laser technology reduce power consumption while maintaining high output.

Tips for Selecting the Right 3 in 1 Laser Welding Machine

Define Your Needs

Identify the primary tasks—welding, cutting, or cleaning—to choose a machine that aligns with your goals.

Evaluate Specifications

Consider power output, compatibility with materials, and available automation features.

Assess Long-Term Value

Weigh the machine’s cost against its benefits, such as increased productivity and reduced operational expenses.

Seek Expert Advice

Consult industry professionals to ensure you select the most suitable model for your requirements.

Laser welding stainless steel has redefined the standards of precision and durability in manufacturing. By understanding the process, leveraging advanced techniques, and staying updated on industry innovations, businesses can unlock the full potential of this transformative technology.