Unlocking the Power of Precision: 2000W Laser Welding Machine

The 2000W laser welding machine has revolutionized industrial welding processes, offering unparalleled precision, speed, and efficiency. Whether you’re in automotive manufacturing, aerospace engineering, or jewelry crafting, this machine promises transformative results.

What is a 2000W Laser Welding Machine?

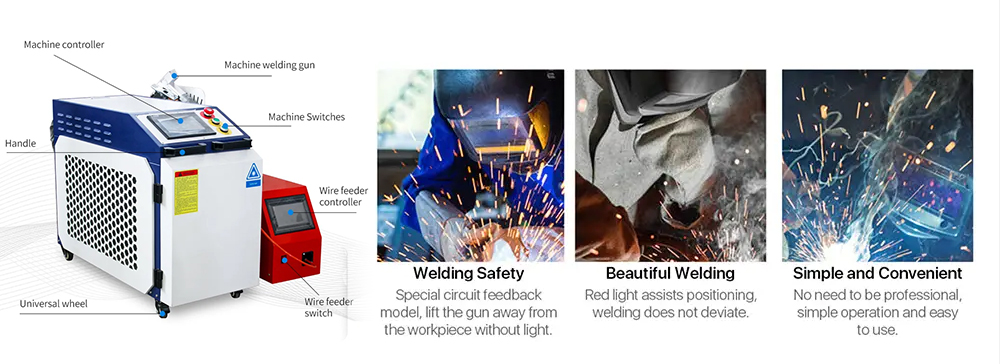

A 2000W laser welding machine is a high-power device designed for complex welding applications. Its 2000-watt output ensures deep penetration and rapid welding, making it ideal for heavy-duty tasks while maintaining accuracy.

Key Features of a 2000W Laser Welding Machine

1. High Power for Versatile Applications

The 2000W output enables users to work with various materials, including steel, aluminum, copper, and titanium, ensuring adaptability across industries.

2. Advanced Cooling Systems

Sophisticated cooling mechanisms prevent overheating, enabling prolonged usage and consistent results.

3. Precision and Speed

A combination of high-energy density and controlled parameters delivers precise welds at unmatched speeds.

4. User-Friendly Interfaces

Touchscreen controls and programmable settings make it easier to operate, even for complex projects.

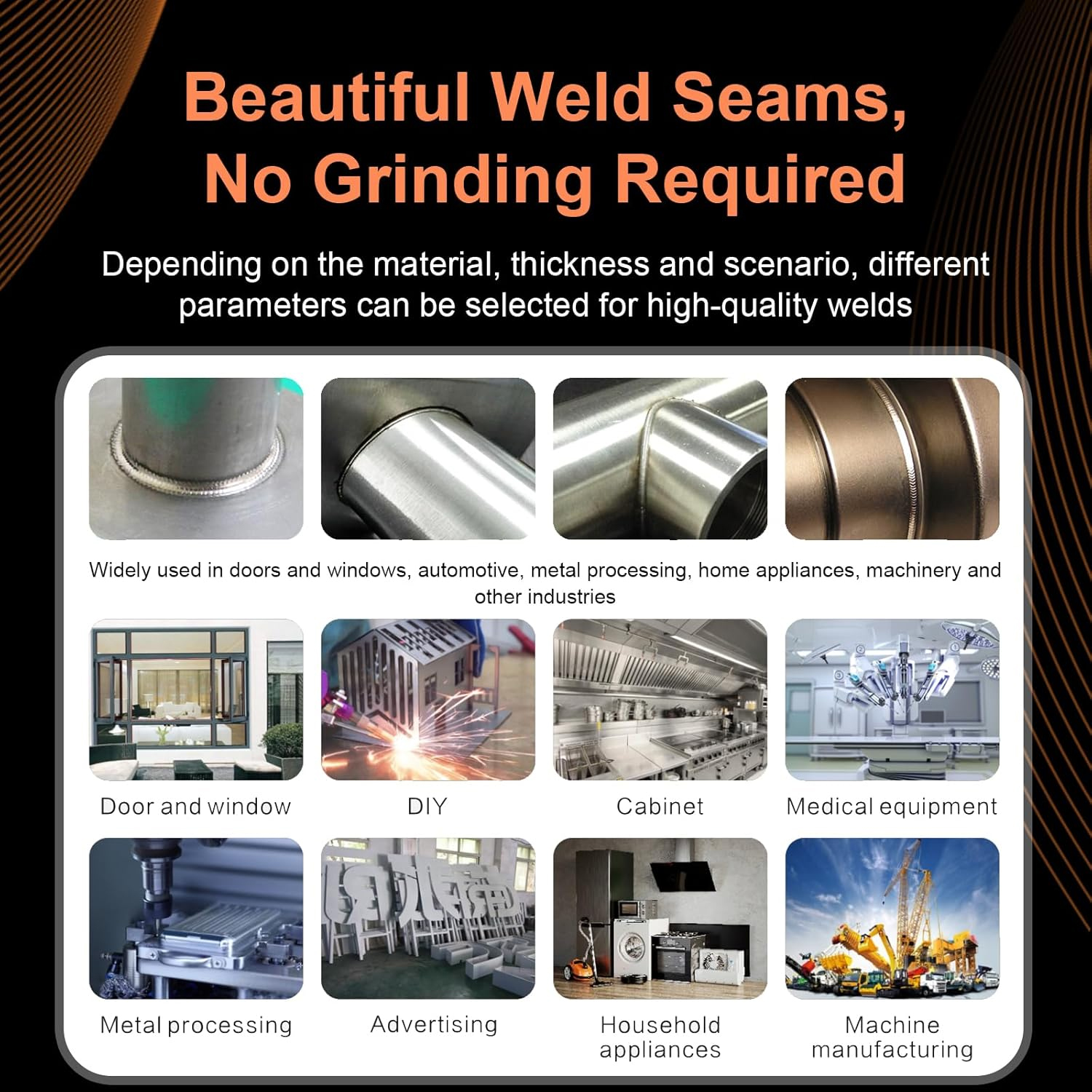

Applications of 2000W Laser Welding Machines

1. Automotive Industry

From car frames to intricate components, these machines streamline the assembly process.

2. Aerospace Engineering

Critical for lightweight and high-strength joints in aircraft manufacturing.

3. Electronics Manufacturing

Delivers precision micro-welding for circuit boards and connectors.

4. Jewelry Crafting

Facilitates seamless repairs and intricate designs for high-end jewelry.

5. Heavy Equipment Repair

Efficiently repairs and refurbishes industrial machinery components.

Factors Influencing the Price of a 2000W Laser Welding Machine

1. Machine Specifications

Higher precision and advanced features can raise the price.

2. Material Compatibility

The ability to weld diverse materials increases versatility but impacts cost.

3. Automation Levels

Machines with AI-assisted welding and automated functions typically cost more.

4. Accessories and Maintenance

Included accessories and ease of maintenance also influence the overall cost.

Price Ranges for a 2000W Laser Welding Machine

| Category | Price Range (USD) | Features |

|---|---|---|

| Entry-Level | $20,000 - $30,000 | Basic functionality for standard materials |

| Mid-Range | $30,000 - $50,000 | Enhanced cooling and automation |

| High-End | $50,000 - $80,000 | AI integration and advanced precision |

Benefits of Investing in a 2000W Laser Welding Machine

1. Enhanced Efficiency

Minimizes welding time while delivering superior results.

2. Cost Savings

Reduces labor and material waste, making it cost-effective in the long term.

3. Durable and Reliable Welds

Ensures strong and lasting joints, even in challenging environments.

How to Choose the Right 2000W Laser Welding Machine

1. Identify Your Needs: Define material types and production volume.

2. Set a Budget: Balance affordability with desired features.

3. Evaluate Support: Check for reliable after-sales service and spare parts availability.

Maintenance Tips for Longevity

• Regularly clean optics and nozzles.

• Inspect cooling systems for leaks or inefficiencies.

• Schedule professional maintenance annually.

• Keep the machine in a clean, dust-free environment.

The Future of 2000W Laser Welding Machines

With advancements in AI and IoT integration, the future of 2000W laser welding machines promises even greater automation, precision, and efficiency. These machines are set to remain indispensable across industries for years to come.

Understanding the features, applications, and pricing of a 2000W laser welding machine can empower professionals to make informed investment decisions.