2000W Laser Cleaner: The Ultimate High-Power Surface Cleaning Solution

Introduction: The Future of Heavy-Duty Laser Cleaning

In industrial settings, rust, oxidation, paint, and coatings pose significant challenges for maintenance and manufacturing. Traditional methods like sandblasting, chemical stripping, and manual grinding are labor-intensive, environmentally hazardous, and often damage the base material.

Enter the 2000-watt laser cleaner, a high-power, precision-based cleaning solution that removes contaminants without abrasives, chemicals, or secondary waste. This next-generation laser technology is revolutionizing industries by enhancing efficiency, reducing operational costs, and improving sustainability.

Why is a 2000W laser cleaner the best choice for industrial-scale cleaning? How does it compare to lower-powered models? In this guide, we explore its technology, applications, pricing, and long-term benefits.

1. What is a 2000W Laser Cleaner?

A 2000-watt laser cleaner is a high-powered, industrial-grade laser cleaning system designed for large-scale and deep-layer contaminant removal. It employs a fiber laser beam to vaporize rust, paint, and coatings without damaging the underlying material.

How Does a 2000W Laser Cleaner Work?

1. The laser beam is directed at the contaminated surface.

2. The coating, rust, or grime absorbs the laser energy, causing rapid heating and instant vaporization.

3. The cleaned surface remains unaffected, ensuring precision without mechanical wear.

4. No waste materialis left behind, reducing environmental impact.

Unlike lower-powered alternatives, a 2000W laser cleaner delivers extreme efficiency, making it suitable for high-speed, industrial applications.

2. Why Choose a 2000W Laser Cleaner?

When dealing with stubborn contaminants on large surfaces, power matters. The 2000W laser cleaner provides a faster, deeper, and more efficient cleaning solution compared to lower-wattage systems.

Comparison of Laser Cleaning Power Levels

| Laser Power | Best Use Cases | Advantages | Disadvantages |

|---|---|---|---|

| 100W – 500W | Light rust, delicate parts, restoration | Affordable, precise, easy to use | Slower for large surfaces |

| 1000W – 1500W | Automotive, mid-range industrial use | Faster cleaning, moderate cost | Limited for deep contamination |

| 2000W+ | Heavy industry, shipbuilding, large-scale production | Ultra-fast, deep cleaning, minimal residue | High initial investment |

Key Benefits of a 2000W Laser Cleaner

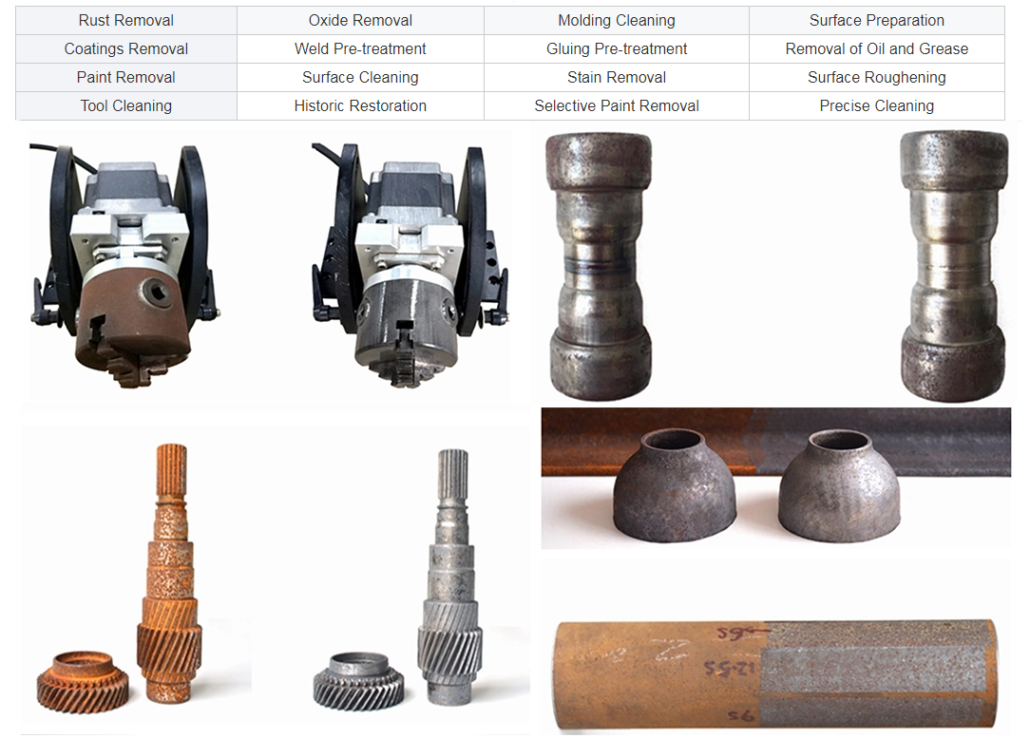

1. Fast & Efficient– Removes rust, paint, and coatings 5–10 times faster than lower-power models.

2. Non-Abrasive & Contact-Free– No sandblasting, no chemical solvents, no surface damage.

3. Eco-Friendly & No Waste– Reduces hazardous waste disposal and airborne dust.

4. Long-Term Cost Savings– Eliminates recurring costs of chemicals and abrasive materials.

5. High Versatility– Suitable for steel, aluminum, iron, concrete, and various alloys.

A 2000W laser cleaner is an investment in efficiency, quality, and long-term cost reduction.

3. Key Applications of a 2000W Laser Cleaner

The industrial-grade power of a 2000W laser cleaning system makes it ideal for high-demand environments.

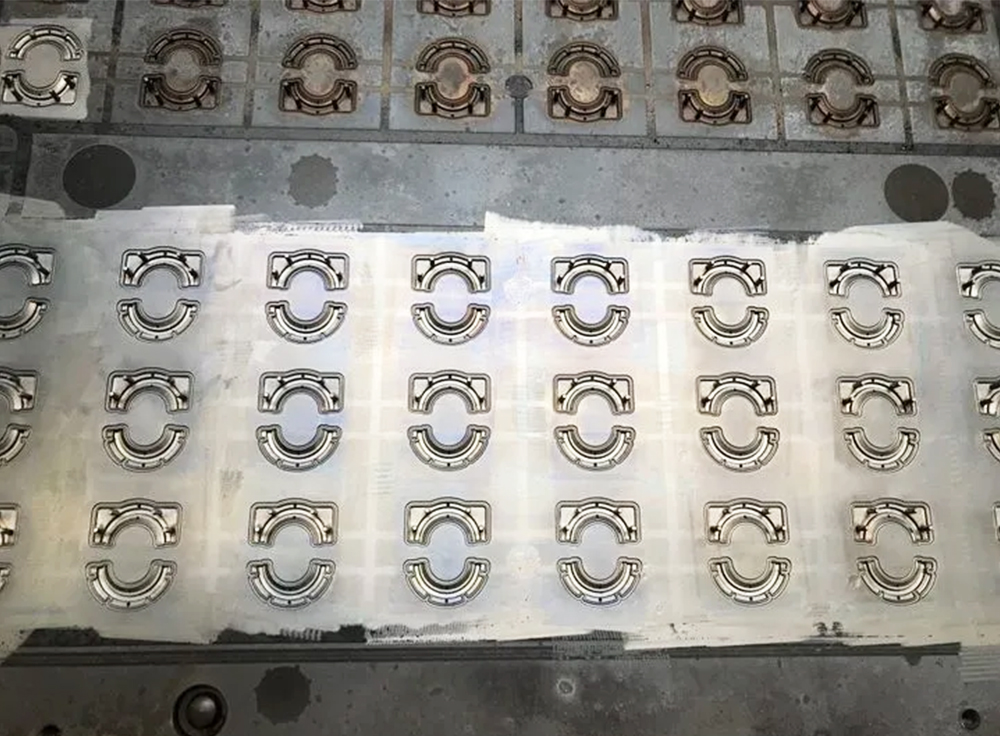

1. Heavy Machinery & Industrial Equipment

• Cleans large-scale manufacturing tools and metal parts.

• Removes stubborn grease, grime, and oxidationfrom industrial surfaces.

• Restores factory equipment without causing wear and tear.

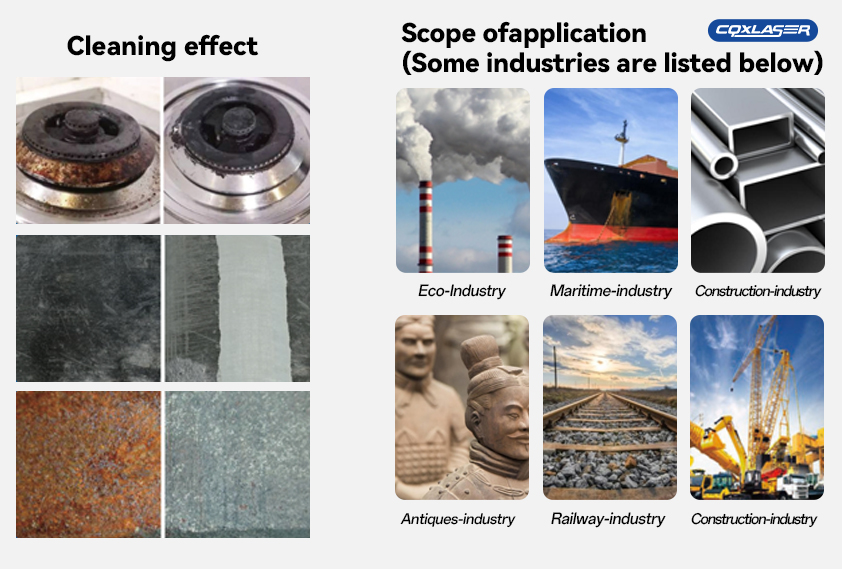

2. Shipbuilding & Marine Industry

• Removes marine rust, barnacles, and corrosionfrom ship hulls.

• Prepares surfaces for repainting and recoating.

• Minimizes downtime in offshore and naval maintenance.

3. Aerospace & Automotive Manufacturing

• Cleans aircraft fuselage, engine components, and mechanical parts.

• Removes oxidation and coatings from vehicle frames and chassis.

• Prepares surfaces for adhesion, bonding, and precision welding.

4. Infrastructure & Metal Processing

• Cleans bridges, rail tracks, pipelines, and industrial structures.

• Restores historical monuments, buildings, and metal sculptures.

The 2000W laser cleaner is the ultimate solution for high-speed, precision-based, large-scale cleaning applications.

4. How Much Does a 2000W Laser Cleaner Cost?

The cost of a 2000W laser cleaning machine varies based on factors like brand, cooling system, automation, and beam control.

Price Range for 2000W Laser Cleaners

| Laser Type | Price Range (USD) | Best For |

|---|---|---|

| Handheld 2000W Laser | $30,000 – $50,000 | Flexible, on-site cleaning |

| Stationary 2000W Laser | $50,000 – $80,000 | Industrial production lines |

| Automated 2000W Laser | $80,000+ | Robotics-integrated, large-scale industries |

Factors Affecting Cost

1. Cooling System– Water-cooled systems are required for continuous operation.

2. Automation– CNC and robotic integration increase costs but enhance precision.

3. Beam Control & Software– Advanced AI-driven precision targeting improves efficiency.

4. Portability vs. Fixed Installations– Mobile models are less expensive than large, factory-based systems.

Despite the high upfront cost, a 2000W laser cleaner reduces long-term operational expenses by eliminating consumables and downtime.

5. Long-Term Savings & Cost Benefits of a 2000W Laser Cleaner

A 2000W laser cleaning system provides industries with significant economic advantages.

1. Eliminates Consumable Costs

• No abrasives, solvents, or chemical agents

• Reduces storage and hazardous waste disposal fees.

2. Boosts Productivity & Reduces Downtime

• Faster cleaning timesreduce labor costs.

• Less maintenancerequired compared to sandblasting equipment.

3. Protects Equipment & Increases Longevity

• Prevents corrosion-related damage.

• Enhances metal durability for long-term performance.

4. Meets Environmental & Safety Regulations

• No hazardous wastealigns with global sustainability standards.

• Reduced airborne contaminantscreate a safer work environment.

For industries requiring fast, sustainable, and cost-effective cleaning solutions, a 2000W laser cleaner is an essential tool.

6. Choosing the Right 2000W Laser Cleaning Machine

To ensure maximum efficiency and performance, consider these factors when selecting a 2000W laser cleaning system:

1. Cooling Type:

° Water-cooledmodels for continuous industrial use.

° Air-cooledfor intermittent, mobile cleaning.

2.Automation Level:

° Handheld systemsfor manual cleaning flexibility.

° CNC-integrated systems for fully automated industrial processing.

3.Software & AI Features:

° Manual controlfor simple operations.

° AI-assisted targetingfor precision cleaning in complex applications.

Selecting the right configuration ensures optimal results for any industrial cleaning requirement.

Final Thoughts: The 2000W Laser Cleaner as the Industrial Standard

A 2000-watt laser cleaner is a game-changer for high-intensity, industrial-scale cleaning. It combines speed, efficiency, and eco-friendliness to deliver unmatched performance in automotive, aerospace, marine, and heavy manufacturing industries.

As industries move toward sustainable, automated solutions, the 2000W laser cleaning system is setting new standards for industrial maintenance and surface restoration.