Unveiling the Cost of Precision: 1500W Laser Welding Machine Price

When discussing industrial-grade precision tools, one question often emerges: What is the price of a 1500W laser welding machine? This article unpacks the factors influencing pricing while guiding potential buyers through the value these machines deliver.

What Makes a 1500W Laser Welding Machine Special?

A 1500W laser welding machine refers to a device operating at a 1500-watt power output, providing the balance between power and finesse. These machines are versatile, capable of welding a variety of metals with unparalleled precision.

Factors Influencing 1500W Laser Welding Machine Price

1. Power and Performance

Higher power translates to deeper penetration and faster welding speeds. The 1500-watt machines fall in the mid-range, offering significant performance at a competitive price.

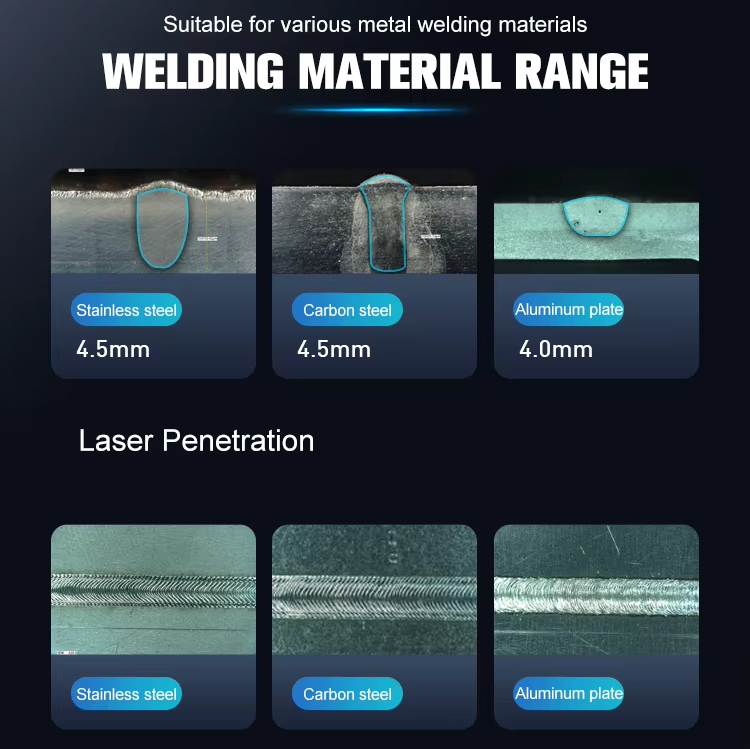

2. Material Compatibility

Machines supporting diverse materials like stainless steel, aluminum, and titanium often command higher prices due to enhanced versatility.

3. Cooling Systems

Efficient cooling systems extend operational hours and ensure consistent performance, influencing overall cost.

4. Technology Integration

Advanced features like AI, programmable settings, and touch-screen interfaces increase the price but improve usability and productivity.

5. Accessories and Add-Ons

Nozzles, protective glasses, and maintenance kits can impact the total cost of ownership.

Cost Breakdown

A general overview of 1500W laser welding machine pricing is as follows:

| Category | Price Range (USD) | Features |

|---|---|---|

| Entry-Level | $10,000 - $15,000 | Basic functionality, limited material support |

| Mid-Range | $15,000 - $25,000 | Higher power, better cooling, wider compatibility |

| High-End | $25,000 - $50,000 | Advanced automation, enhanced precision |

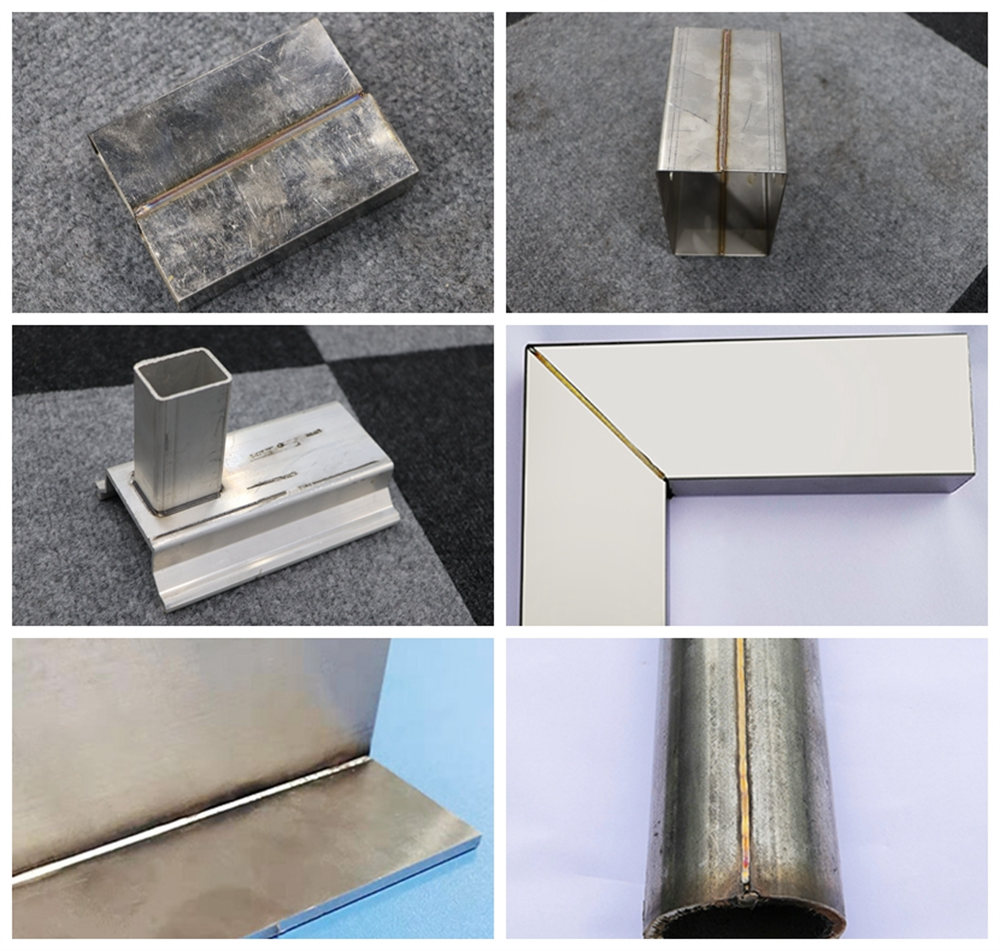

Applications of 1500W Laser Welding Machines

1. Automotive Industry

Used for joining critical components, ensuring durability and lightweight construction.

2. Medical Equipment Manufacturing

Enables precise welding of surgical instruments and implants.

3. Aerospace Components

Critical for creating strong yet lightweight joints in aircraft manufacturing.

4. Jewelry Making

Allows intricate designs and seamless repairs, particularly for precious metals.

5. Electronics

Facilitates micro-welding in circuit boards and connectors.

Why Invest in a 1500W Laser Welding Machine?

1. Cost-Effectiveness

While initial investment may seem high, the machine’s efficiency reduces long-term operational costs.

2. Precision

Achieves flawless welds with minimal waste, reducing post-weld processes.

3. Versatility

Supports a broad spectrum of applications across industries.

How to Choose the Right Machine

When investing in a 1500W laser welding machine, consider the following:

1. Application Needs: Match machine capabilities to project requirements.

2. Budget Constraints: Balance features with affordability.

3. Support and Maintenance: Opt for models with accessible customer service and spare parts.

Maintaining Your Investment

To maximize the lifespan of your machine:

• Perform regular cleaning of lenses and nozzles.

• Monitor and refill cooling fluids as needed.

• Schedule professional maintenance checks.

• Store in a controlled environment to prevent damage.

Future Trends in Laser Welding Technology

The laser welding industry is evolving rapidly, with trends like AI-assisted welding and compact, portable machines gaining traction. These innovations promise even greater efficiency, accuracy, and affordability, making tools like the 1500W laser welding machine indispensable for future applications.

Understanding the pricing and value of a 1500W laser welding machine can simplify purchasing decisions, helping professionals achieve cost-effective and precise results in their projects.