The Power of a 1000W Rust Cleaning Laser

Rust removal has always been a daunting task, especially when dealing with industrial-grade equipment or valuable items. Enter the 1000W rust cleaning laser, a revolutionary tool that combines cutting-edge technology with unmatched precision. This device has redefined how we approach rust removal, providing an eco-friendly, efficient, and highly accurate solution for various industries and applications.

What is a 1000W Rust Cleaning Laser?

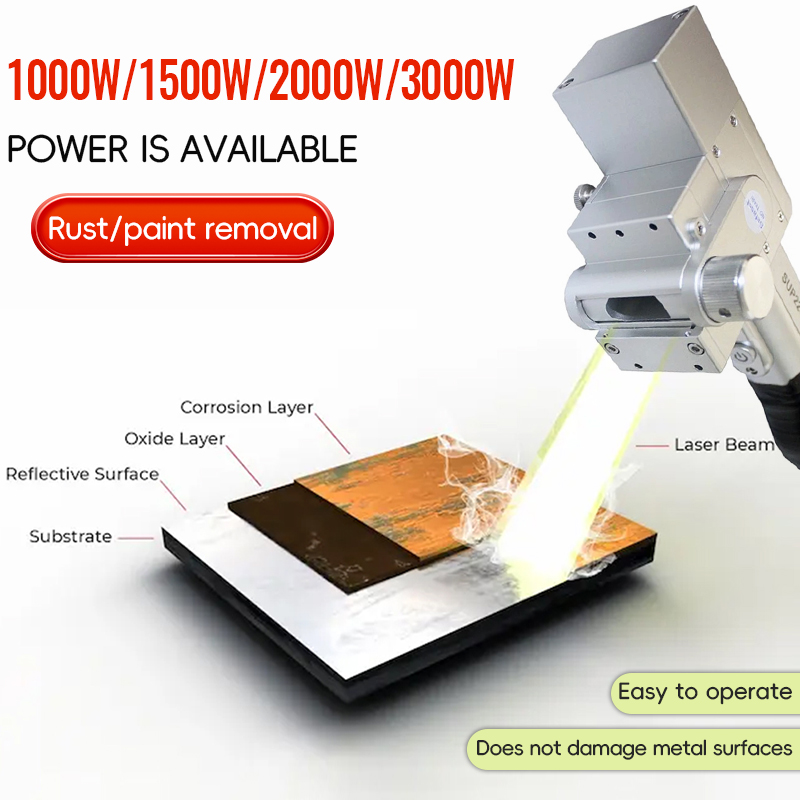

A 1000W rust cleaning laser is a high-powered device designed to remove rust, paint, and other contaminants from metal surfaces using laser technology. The laser beam interacts with the surface layer, vaporizing or breaking down rust particles without damaging the underlying material.

How Does It Work?

1. Emission of Laser Beam: A focused laser beam targets the rusted surface.

2. Heat and Energy Absorption: Rust particles absorb the laser’s energy, causing them to break apart.

3. Residue Removal: The debris is safely removed, leaving a clean and smooth surface behind.

Advantages of Using a 1000W Rust Cleaning Laser

1. High Efficiency

With a power output of 1000W, this laser can clean large areas quickly and effectively, reducing downtime and increasing productivity.

2. Environmentally Friendly

This method eliminates the need for harsh chemicals or abrasive materials, making it a sustainable and eco-conscious choice.

3. Precision Cleaning

The laser targets rust and contaminants without affecting the surrounding area, ensuring a clean and undamaged surface.

4. Cost-Effective

Although the initial investment might seem high, the durability and efficiency of the 1000W laser reduce long-term operational costs.

5. Versatility

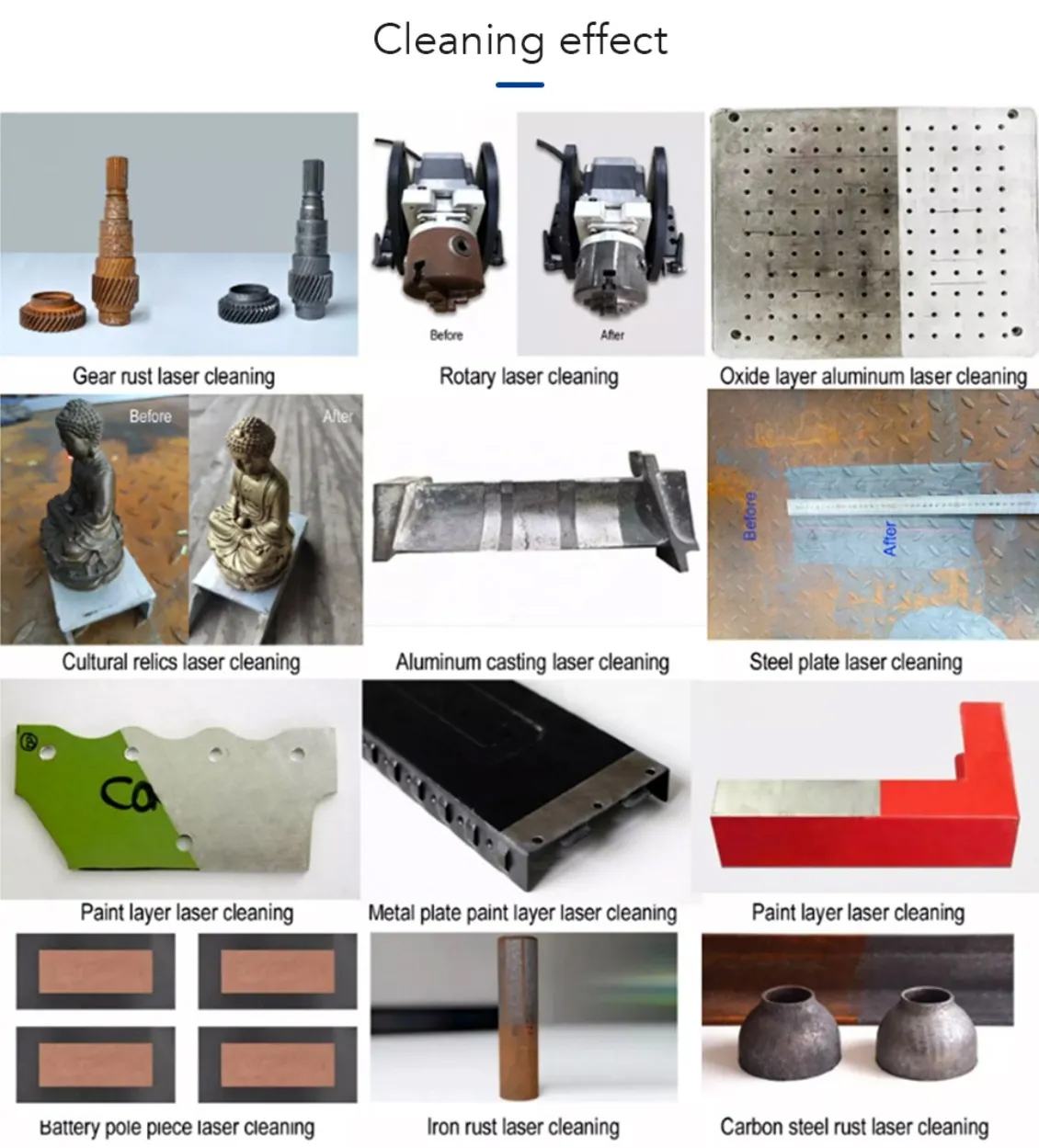

From industrial machinery to delicate tools, this laser adapts to a wide range of cleaning applications.

Applications of the 1000W Rust Cleaning Laser

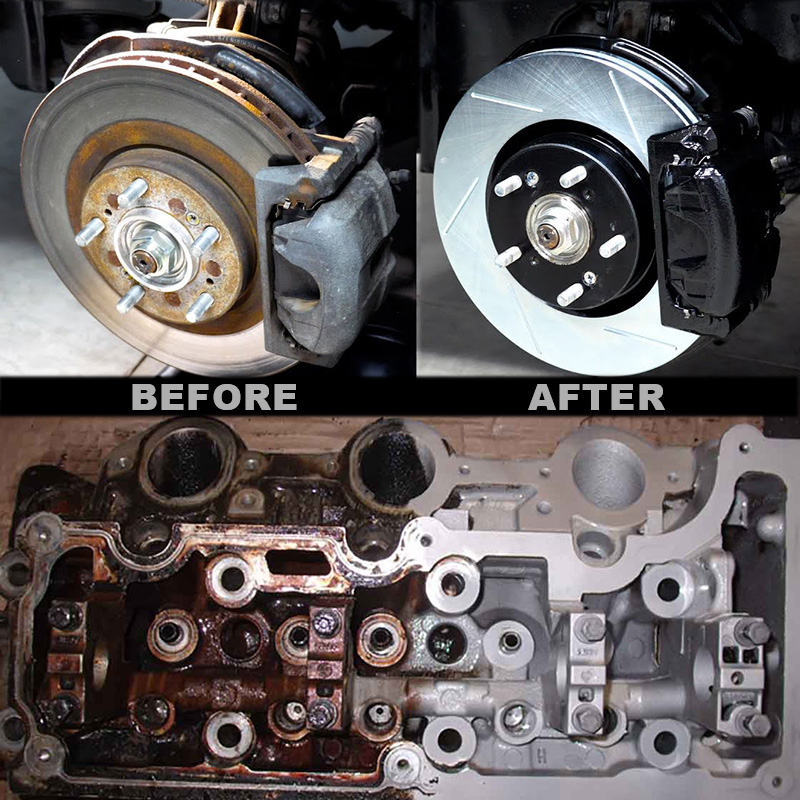

1. Industrial Equipment Maintenance

Restore machinery, tools, and equipment to their original condition without dismantling them.

2. Automotive Restoration

Remove rust and old paint from car parts, frames, and body panels with precision.

3. Shipbuilding and Marine Maintenance

Clean rust and contaminants from ship hulls, decks, and other marine components.

4. Historical Artifact Conservation

Safely remove rust from valuable historical artifacts and metal sculptures.

5. Surface Preparation

Prepare metal surfaces for welding, painting, or coating by removing rust and other contaminants.

Factors to Consider When Choosing a 1000W Rust Cleaning Laser

1. Power Requirements

Ensure your workspace can handle the power demands of a 1000W laser.

2. Surface Material

Consider the type of material you’ll be cleaning, as some surfaces may require specific laser settings.

3. Safety Features

Look for lasers equipped with safety mechanisms such as automatic shut-off and protective enclosures.

4. Portability

Portable models are ideal for on-site applications and smaller workshops.

5. Cost and Maintenance

Evaluate the overall cost, including maintenance, training, and consumables.

Cost Analysis of a 1000W Rust Cleaning Laser

The price of a 1000W rust cleaning laser varies depending on its features, brand, and accessories. Here are some factors influencing the cost:

1. Power Output: Higher wattage typically results in a higher price.

2. Automation Level: Fully automated systems are more expensive but offer increased efficiency.

3. Portability: Compact and portable models are often pricier due to their design and convenience.

4. Additional Features: Built-in cooling systems, advanced software, and safety features contribute to the overall cost.

On average, a 1000W laser can cost between $20,000 and $50,000, but the long-term savings on consumables and labor make it a worthwhile investment.

Comparing Laser Rust Cleaning with Traditional Methods

| Feature | Laser Rust Cleaning | Traditional Methods |

|---|---|---|

| Precision | High | Moderate |

| Surface Preservation | Excellent | Varies |

| Chemical-Free Process | Yes | No |

| Speed | Fast | Slow |

| Eco-Friendly | Yes | No |

Innovations in Rust Cleaning Lasers

1. AI-Driven Cleaning

Artificial intelligence enhances the laser’s ability to identify and clean rusted areas automatically.

2. Enhanced Portability

Newer models are lighter and more compact, allowing for easier transportation and on-site use.

3. Energy Efficiency

Advanced designs consume less power while maintaining high performance, reducing operating costs.

4. Multi-Material Capability

Some models can clean not only metal but also other materials like stone or plastic, increasing their versatility.

How to Operate a 1000W Rust Cleaning Laser Safely

1. Wear Protective Gear

Always use safety glasses and appropriate clothing when operating the laser.

2. Ensure Proper Ventilation

Laser cleaning can produce fumes and particles, so adequate ventilation is crucial.

3. Follow Manufacturer Guidelines

Adhere to the provided manual for optimal settings and maintenance procedures.

4. Regular Maintenance

Keep the laser lens clean and inspect the machine regularly to ensure consistent performance.

Future of 1000W Rust Cleaning Lasers

The 1000W rust cleaning laser represents a significant leap forward in surface restoration technology. As advancements continue, these devices will become more affordable, efficient, and versatile, solidifying their role as an essential tool across industries. For those seeking precision, sustainability, and long-term value, investing in this technology is a forward-thinking decision.