Welcome to CQXLaser! Our working hours are 7×24 hours

Welcome to CQXLaser! Our working hours are 7×24 hours

Imagine a world where cleaning is effortless, precise, and eco-friendly—this is the promise of the deep cleaning laser. This innovative technology is reshaping industries, offering unparalleled efficiency and sustainability. But what exactly is a deep cleaning laser, and how can it benefit you? Let’s dive deep into the technology, applications, and considerations for adopting this advanced solution.

A deep cleaning laser is a powerful tool that uses high-intensity laser beams to remove contaminants, such as rust, paint, grease, and other residues, from a variety of surfaces. Unlike traditional cleaning methods, it achieves superior results without abrasives, chemicals, or water, making it a sustainable and efficient alternative.

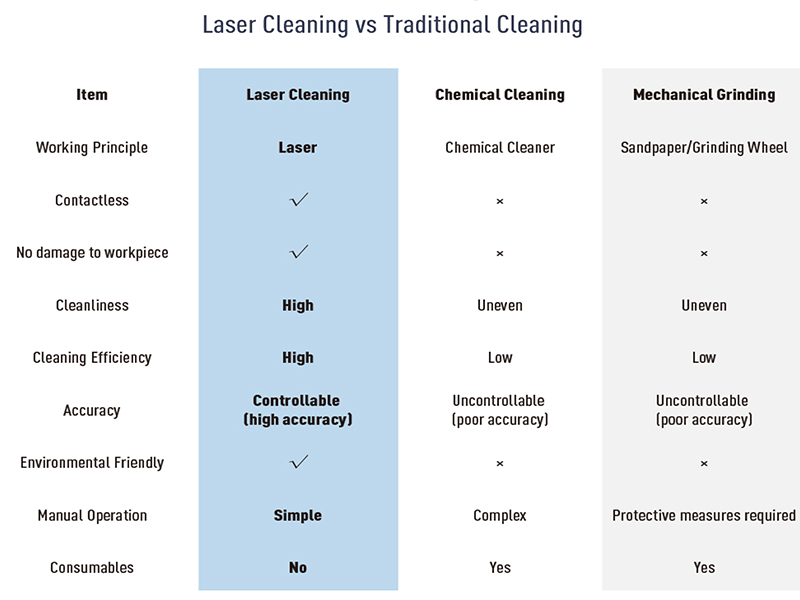

1. Non-Contact Cleaning: Ensures no damage to the substrate material.

2. Precision and Control: Targets only the areas needing cleaning.

3. Environmentally Friendly: Eliminates the need for harmful chemicals or waste disposal.

4.Versatility: Suitable for metals, ceramics, and composites.

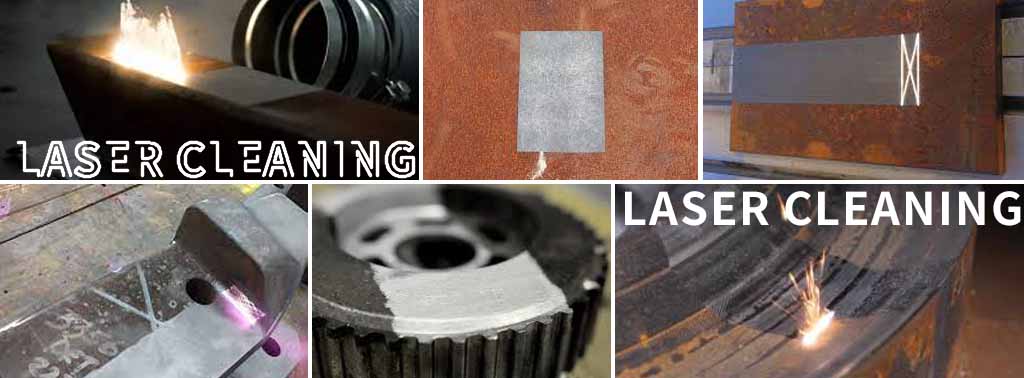

Deep cleaning lasers emit focused light energy that interacts with contaminants on the surface. This interaction causes the contaminants to evaporate or disintegrate, leaving the underlying material untouched. The process is non-invasive, precise, and incredibly fast, making it ideal for delicate and industrial applications alike.

• Laser Ablation: The primary mechanism where contaminants are vaporized using intense heat.

• Selective Absorption: Lasers target specific materials based on their absorption properties, ensuring precise cleaning.

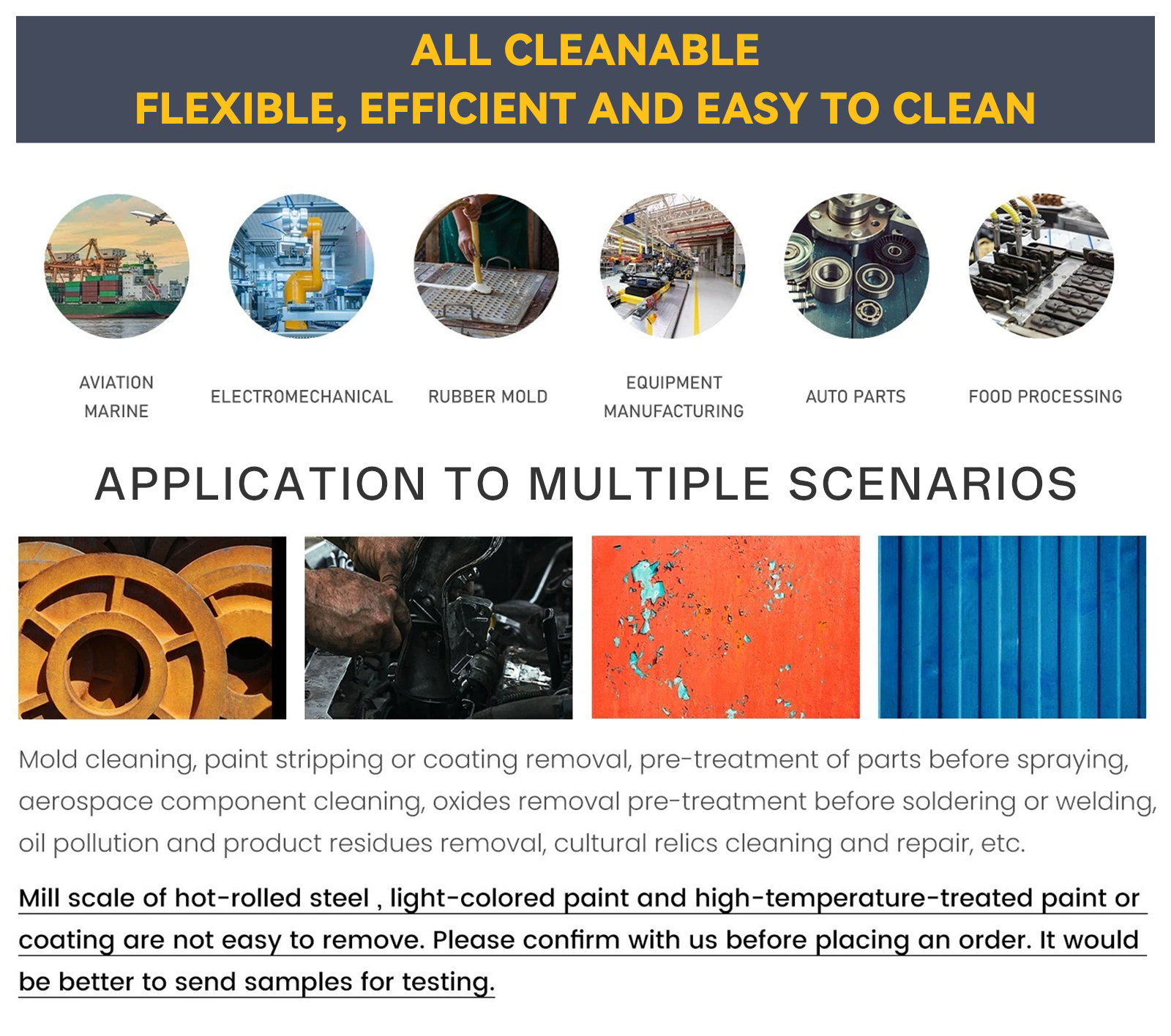

Efficiently remove rust, oil, and dirt from machinery, ensuring optimal performance and longevity.

Safely strip paint and coatings from vehicles, aircraft, or other surfaces without damaging the base material.

Delicately clean historical artifacts, monuments, and sculptures, preserving their integrity.

Clean delicate electronic components without the risk of abrasion or residue.

Prepare surfaces for welding, coating, or adhesive bonding by ensuring they are free from contaminants.

Deep cleaning lasers significantly reduce cleaning time compared to traditional methods.

Though the initial investment might be higher, the long-term savings in maintenance, consumables, and labor are substantial.

These lasers eliminate the need for harsh chemicals, protecting both the environment and the operator.

Their non-contact nature ensures quick cleaning without the risk of damage or lengthy drying times.

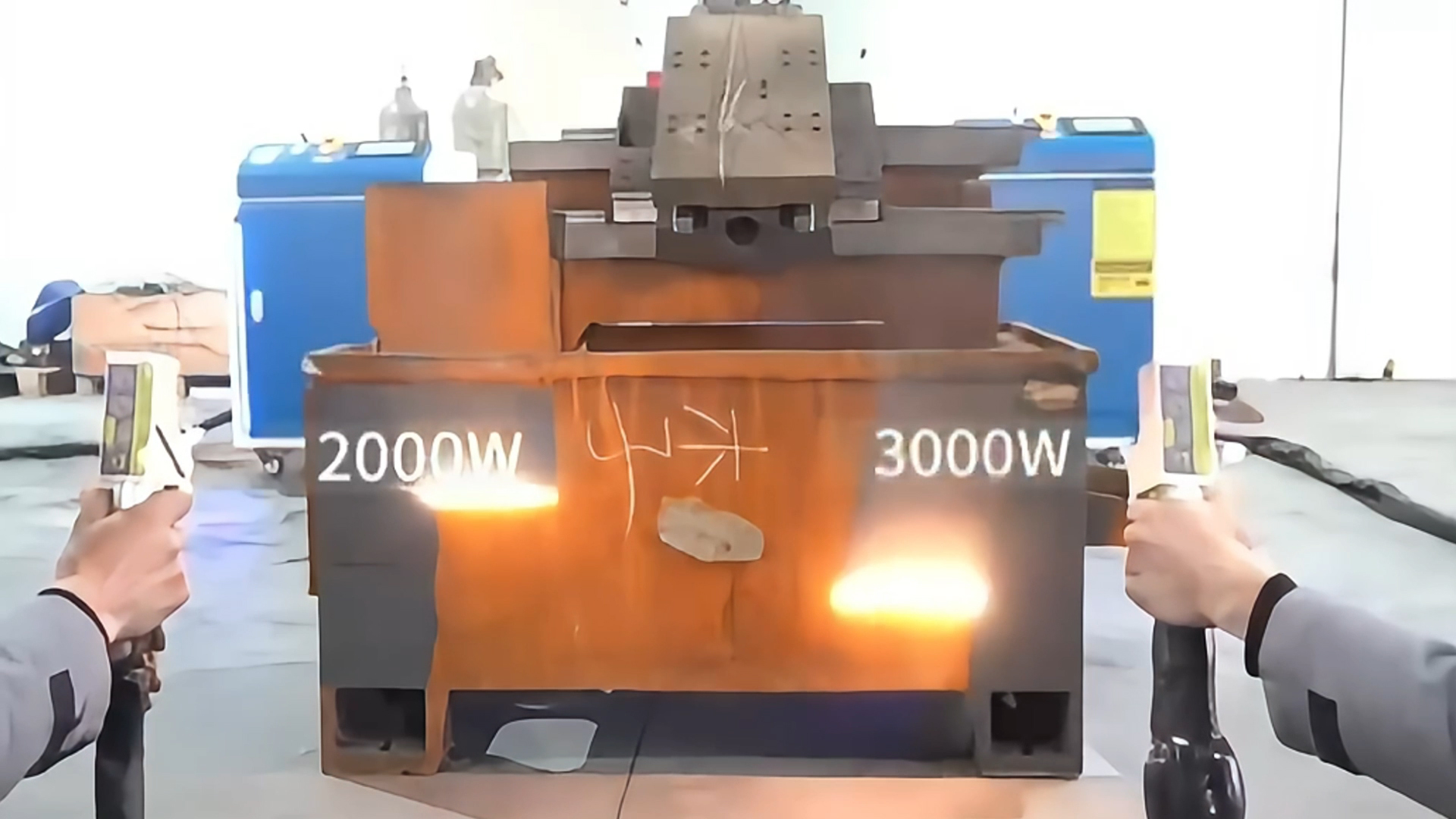

Higher wattage lasers (e.g., 100W or more) offer faster cleaning speeds but may not be necessary for every application.

Ensure the laser is suitable for the materials you frequently work with.

Portable models are ideal for on-site applications, while stationary systems suit factory setups.

Prices range based on features, power, and customization. Evaluate the long-term ROI before making a decision.

Check if the manufacturer provides training, maintenance, and easy access to spare parts.

• Pros: Effective for specific contaminants.

• Cons: Generates waste, requires proper disposal, and can damage sensitive surfaces.

• Pros: Suitable for large-scale operations.

• Cons: May cause surface damage and produce airborne dust.

• Pros: Non-contact, eco-friendly, and precise.

• Cons: Higher upfront cost but justified by long-term savings.

The price of a deep cleaning laser can range from $8,000 to $50,000, depending on factors such as power output, features, and manufacturer.

1. Machine Features: Advanced models with automation or enhanced cooling systems cost more.

2. Power Output: Higher wattage machines offer better performance but at a higher price.

3. Customization: Tailored designs for specific applications may increase costs.

• Training and Installation: Often charged separately.

• Maintenance: Minimal but necessary for long-term performance.

Yes, when operated with proper training and safety equipment, they are highly safe.

While effective on metals and ceramics, testing is recommended for sensitive surfaces like wood or fabric.

Industries such as automotive, aerospace, cultural restoration, and electronics manufacturing see significant advantages.

With proper maintenance, these machines can last over 50,000 hours of operation.

Advancements in laser technology are expected to make these systems even more accessible and efficient. Future trends may include:

• AI Integration: For automated and adaptive cleaning processes.

• Compact Designs: Enhancing portability for diverse applications.

• Increased Affordability: As technology evolves, prices are likely to become more competitive.

Deep cleaning lasers represent the pinnacle of modern cleaning technology, offering unmatched precision, efficiency, and sustainability. Whether for industrial use or delicate restoration, they are a worthwhile investment for anyone seeking innovative cleaning solutions.